Plug-and-play industrial adapter for intelligent manufacturing and application thereof

An intelligent manufacturing and adapter technology, applied in the direction of comprehensive factory control, instrument, program control, etc., can solve the problems that the production process cannot be self-organized and self-adapted, resource data and information cannot be shared, and consume a lot of time and cost, so as to optimize production execution activities, ease the reconfiguration process, and increase productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

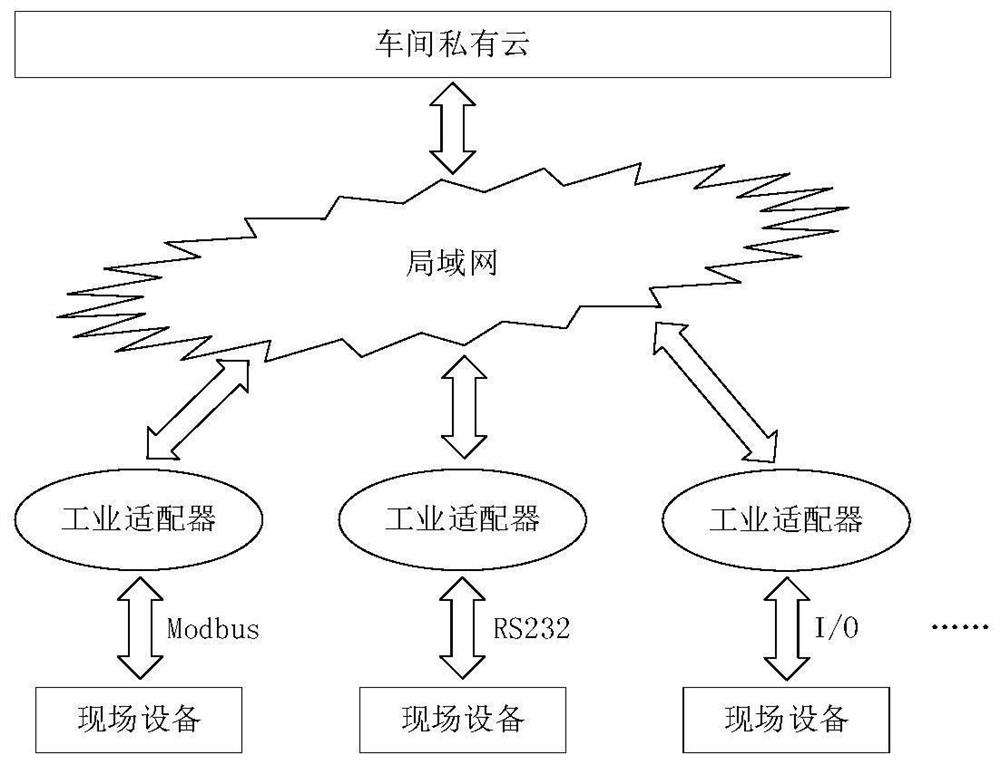

[0051] combine figure 1As shown, this embodiment provides a plug-and-produce industrial adapter for intelligent manufacturing. The industrial adapter deeply integrates emerging cloud technology on the basis of the traditional discrete manufacturing environment, and utilizes the powerful computing power of the workshop private cloud to centralize coordination And manage heterogeneous production equipment, optimize the production process, so as to reduce the time and cost overhead caused by the reconstruction process of products, resources and processes, including:

[0052] In this embodiment, the industrial adapter includes: an AutomationML model, a model conversion module, an OPC UA server dynamically generated by the model conversion module, a Web Server service module, and a communication protocol mapping module;

[0053] Among them, the AutomationML model is used to describe the collection of all internal data elements of physical resources, as well as information such as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com