Electrode adjustable structure of safe and efficient submerged arc furnace

A submerged arc furnace and electrode technology, applied in the direction of furnace, electric furnace heating, furnace components, etc., can solve the problems of submerged arc furnace production efficiency drop, electrode electrothermal efficiency drop, poor safety, etc., achieve high electrode utilization rate, improve continuous work duration and the effect of avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

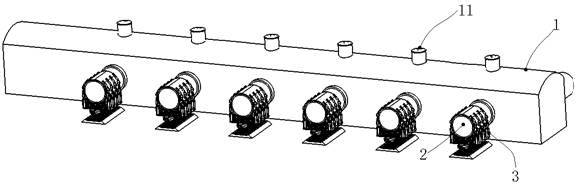

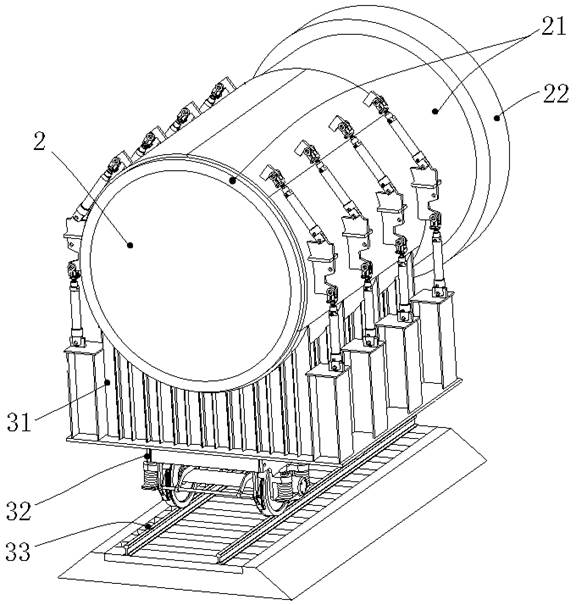

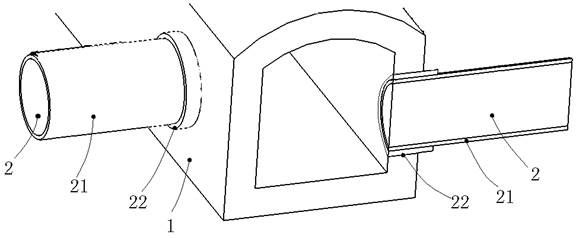

[0026] An electrode controllable structure of a safe and high-efficiency submerged arc furnace, including a furnace body 1, distributed on the side wall of the furnace body 1 and provided with electrodes 2 through it, and the electrodes 2 move toward the furnace body 1 through a moving device 3 Inner retractable mobile setting; the mobile device 3 includes a guide rail 33, a holder 31, an insulating support and a chassis 32, and the chassis 32 is arranged on the guide rail 33 and moved back and forth along the guide rail 33, the described The insulating support is fixed on the chassis 32, and the holder 31 is fixedly connected on the insulating support; the top of the holder 31 is provided with a clamping hole 316, and the upper part of the clamping hole 316 A clamping plate that can be opened and closed is provided, the outer end of the electrode 2 is fixedly sleeved in the clamping hole 316, the electrode 2 is arranged horizontally, and the cross section of the electrode 2 is...

no. 2 example

[0031] Other technical features In the same situation as the first embodiment, the electrodes 2 are arranged on the left and right side walls of the furnace body 1, and the electrodes 2 on the left and right side walls are arranged alternately. .

no. 3 example

[0033] Other technical features In the case of the same as the first embodiment or the second embodiment, the clamping plate is set as a split opening structure, the lower part of the clamping hole 316 is an arc-shaped groove 315, in the A first clamping plate 311 and a second clamping plate 312 are sequentially hinged on both sides of the arc-shaped groove 315, and the arc-shaped groove 315, the first clamping plate 311 and the second clamping plate 312 form a circle The cylindrical clamping hole 316 has a hinge plate 313 distributed on the outer wall of the first clamping plate 311, and the clamper 31 is between the second clamping plate 312 and the hinge plate 313. A telescoping device 31 is hinged between the lower part and the hinge plate 313 .

[0034] The working principle of the present invention: the mixed material is added into the submerged arc furnace through the feeding port above the submerged arc furnace, and the submerged arc electric heat is generated between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com