Deep water bare rock foundation construction device and method

A technology for foundation construction and deep-water bare rock, which is applied in infrastructure engineering, protection devices, water conservancy projects, etc. It can solve problems such as hidden safety hazards and high construction costs, simplify the structure, reduce total weight and strength requirements, and improve accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

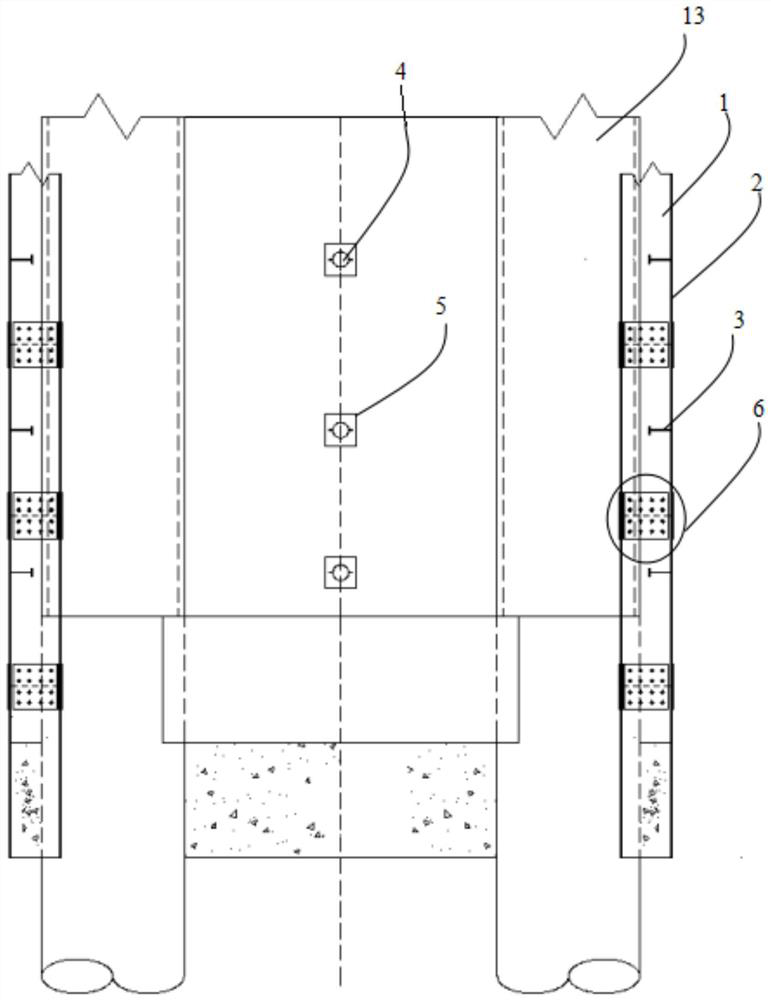

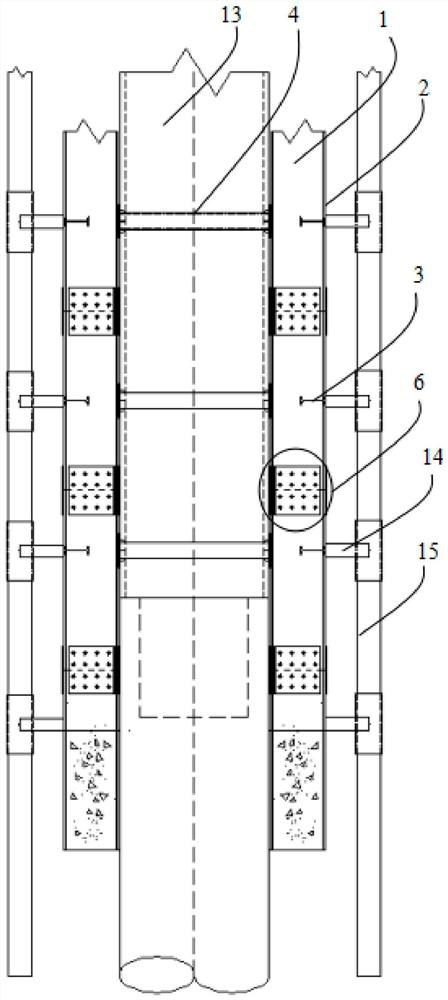

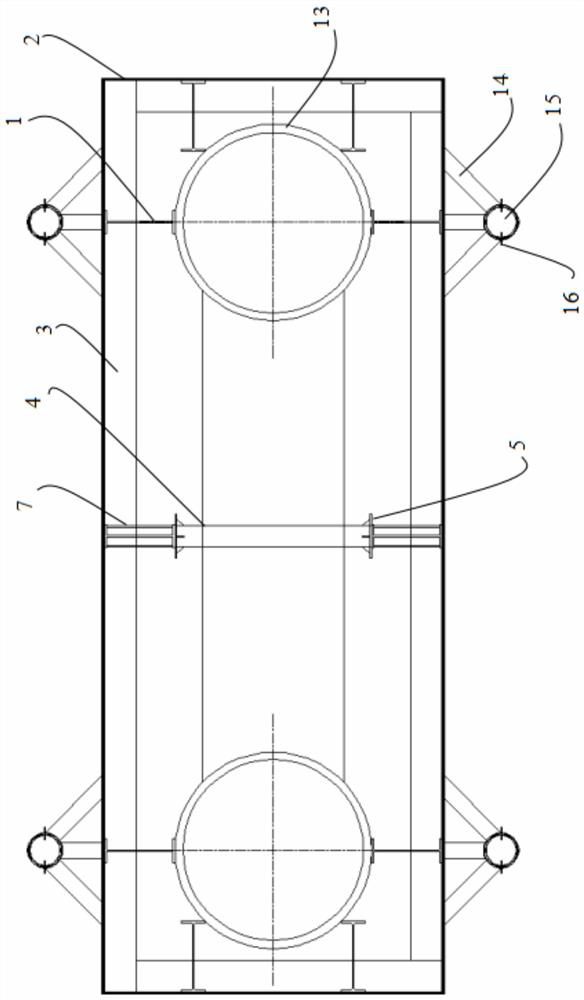

[0058] As a kind of embodiment of the deep water bare rock foundation construction method provided by the present invention, specifically comprise the following steps:

[0059] Build a trestle bridge as a temporary construction work platform;

[0060] Assemble the first section of steel casing and the second section of steel casing on the trestle bridge, install part of the casing, and install the connection and fixing system on the outer wall of the steel casing. First, two sections of steel casing are used to facilitate the vertical state of the slide bar;

[0061] The crane lifts the assembled steel box of the first section, the steel box of the second section, the casing and the connection and fixing system, and lowers them to a suitable height;

[0062] Use other cranes to hoist the steel pipes, insert 4 steel pipes to the bare rock bottom as sliding rods, insert pins, unhook the crane, and use steel pipes to support the double-section steel casing and casing in the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com