Material receiving system and asphalt mixing plant

A technology of receiving vehicles and receiving ports, which is applied in roads, road repairs, roads, etc., and can solve problems that affect the efficiency of receiving vehicles, full of materials in the bucket, overflow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

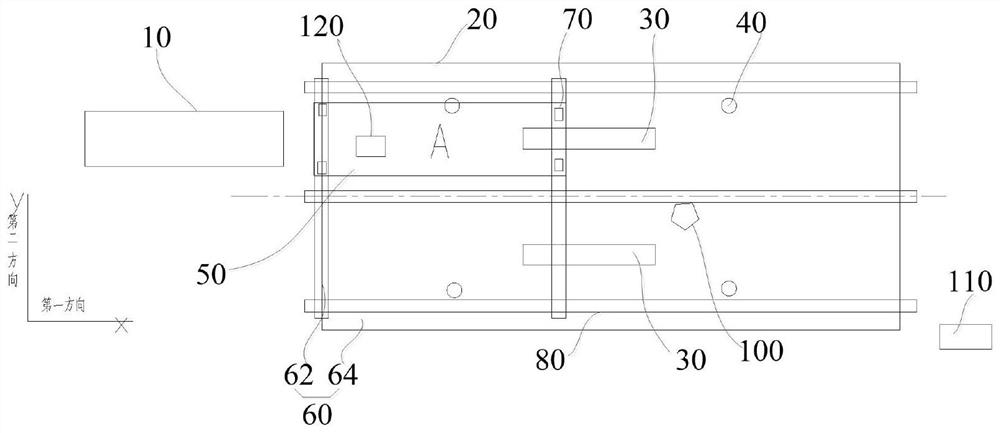

[0046] Specifically, such as figure 1 As shown, in the first embodiment of the present invention, the mobile platform 80 includes a carrying platform 50 , a rail assembly 60 and a driving assembly 70 . Wherein, the carrying platform 50 is used to carry the receiving vehicle 10; the guide rail assembly 60 is located below the carrying platform 50; the driving assembly 70 is connected with the carrying platform 50 and the control system 110 respectively, and the driving assembly 70 can drive the carrying platform 50 on the guide rail assembly 60 Sliding, the control system 110 controls the driving assembly 70 to adjust the relative position of the carrying platform 50 and the material receiving port 30 .

[0047] In the above arrangement, the loading platform 50 is driven to slide on the guide rail assembly 60 by the driving assembly 70, so that the material receiving vehicle 10 is moved to the material receiving position. Since the driving efficiency of the drive assembly 70 i...

Embodiment 2

[0065] The difference between embodiment two and embodiment one is:

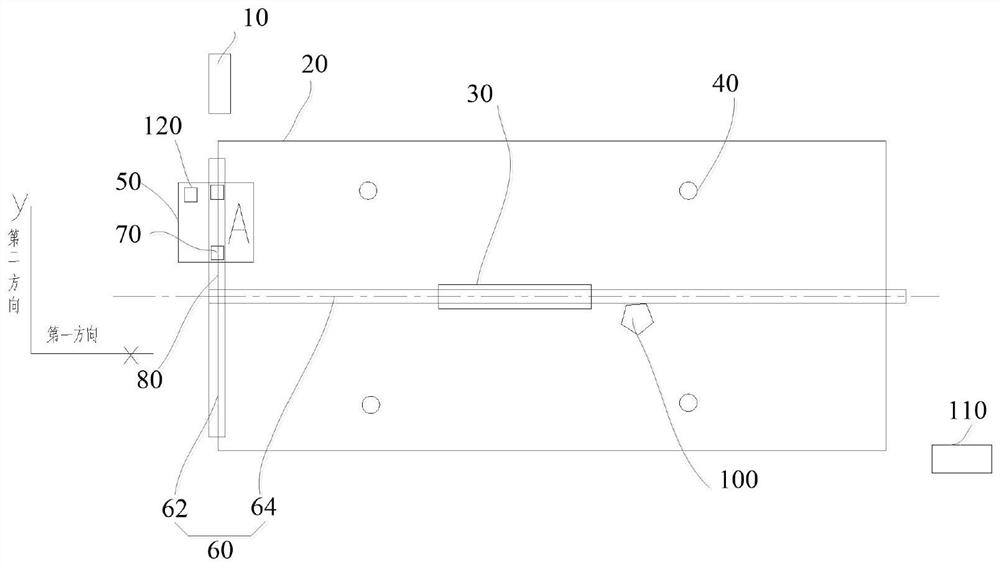

[0066] like figure 2 As shown, in the second embodiment of the present invention, the guide rail assembly 60 includes a first guide rail 62 and a second guide rail 64 , and the first guide rail 62 and the second guide rail 64 are connected in a T shape.

[0067] In the above configuration, the guide rail assembly 60 has a simple structure and is easy to manufacture. This kind of guide rail assembly 60 saves production costs while ensuring that the material receiving cart 10 moves to the material receiving position below the material receiving port 30 . In addition, since the guide rail assembly 60 has a simple structure, it is convenient for subsequent replacement.

[0068] Embodiment 2 is the same as Embodiment 1 in other structures, and will not be repeated here.

[0069] It should be noted that the material receiving system in the second embodiment of the present application is mainly applied to the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com