Steel track beam mounting mould and steel track beam mounting method

A technology of steel track beams and molds, which is applied in the direction of track, track laying, track maintenance, etc. It can solve the problems of inability to make precise adjustments during the adjustment process, affect the installation accuracy of steel track beams, and increase the labor intensity of operators, so as to reduce the quality Risk reduction, shortening of work efficiency, improvement of work efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

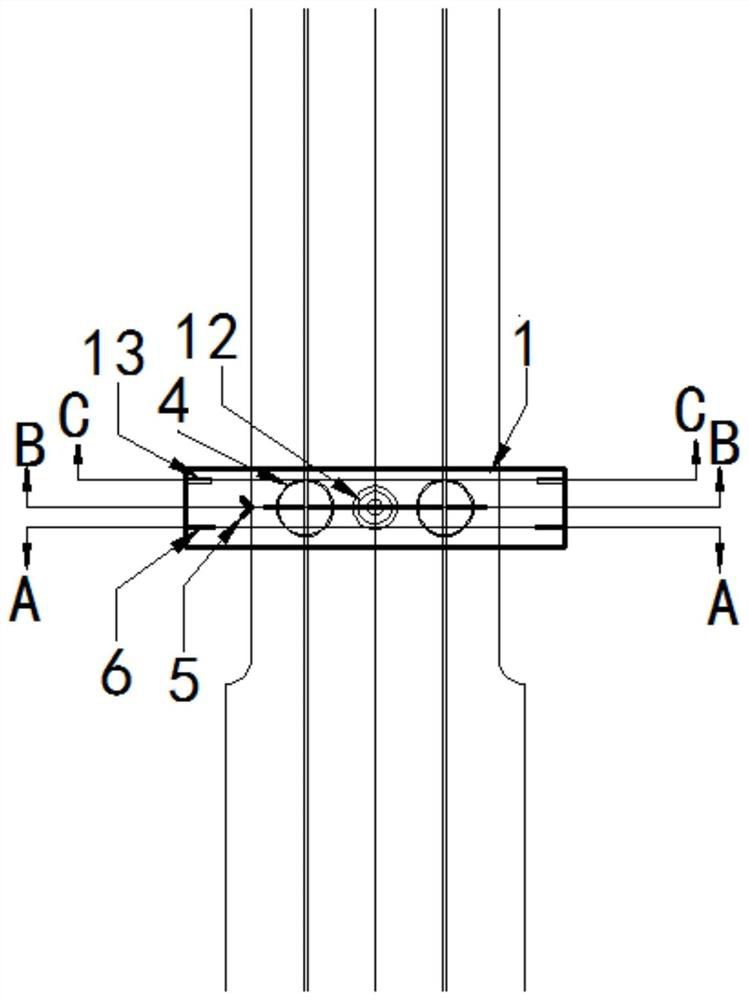

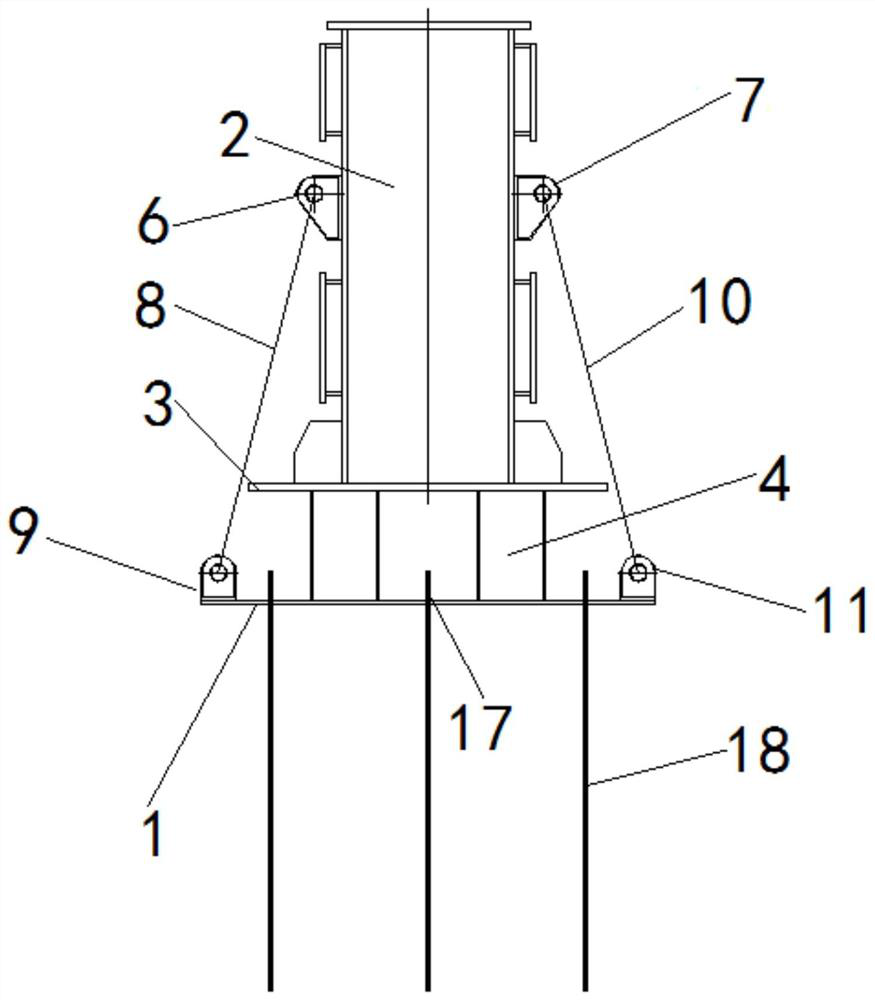

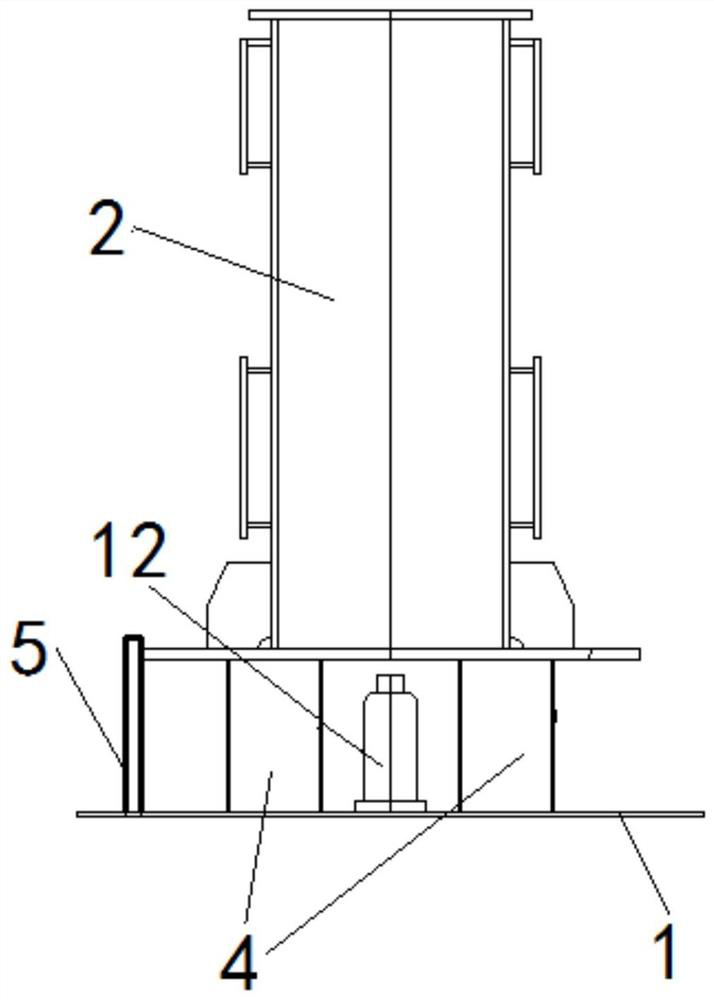

[0026] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the role and working principle of the various parts, etc., will be further described. Detailed instructions:

[0027] as attached figure 1 - attached Figure 4 As shown, the present invention is a steel track beam installation mold, including a mold bottom plate 1, the tire mold bottom plate 1 is connected with a reserved steel bar 18, a steel beam bottom plate 3 is arranged at the bottom of the steel beam body 2, the mold bottom plate 1 and the steel beam Adjusting pipe 4 is set between bottom plates 3, angle steel 5 is also set on tire bottom plate 1, one side of steel beam bottom plate 3 is connected with angle steel 5, steel beam ear plate I6 is set on one side of steel beam body 2, and steel beam ear plate I6 is set on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com