Turnover machine for insulation board production

A heat preservation board and turning machine technology, which is applied in the direction of conveyors, storage devices, transportation and packaging, etc., can solve the problems of low efficiency and achieve the effect of improving turning efficiency and strong continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

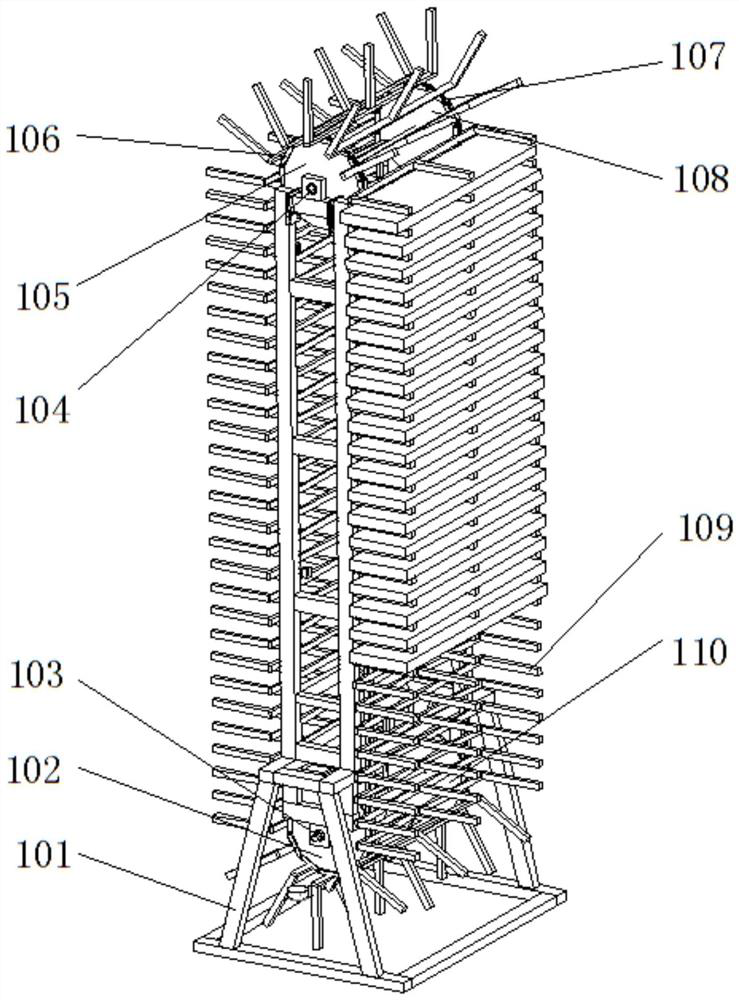

[0028] Such as figure 1 and figure 2As shown, the present invention provides a turning machine for insulation board production, including a support frame 101 and a circulation transmission mechanism installed on the support frame 101. The bottom of the support frame 101 is supported on the ground, and its height is adapted to the height of the curing frame in the production line. Height, several insulation board supports 109 are installed on the circulation transmission mechanism, and the circulation transmission mechanism can drive several insulation board supports 109 to do the circular circulation movement, and several insulation board supports 109 are in the shape of multiple on one side of the circulation transmission mechanism Layers are arranged at intervals, and each insulation board support 109 can make the insulation board to be conveyed lie flat on it and support the insulation board to be conveyed. Wherein, the circulation transmission mechanism includes a left t...

specific Embodiment approach 2

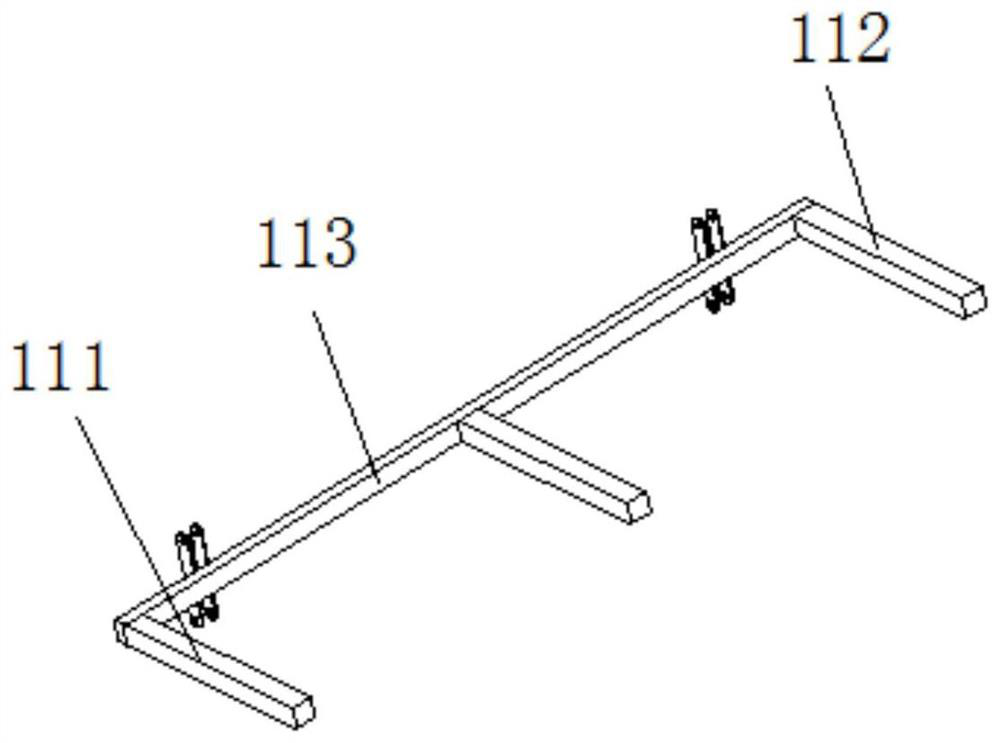

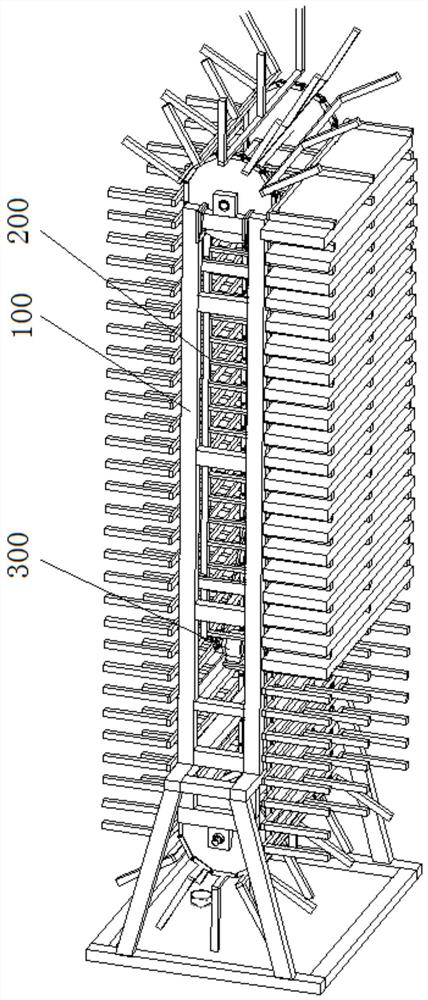

[0032] Such as image 3 As shown, this specific embodiment is improved on the basis of specific embodiment 1, including a turning machine 100, a push frame 200 and a drive mechanism 300, the drive mechanism 300 is installed on the support frame 101, and the push frame 200 is installed on the drive mechanism 300 And supported by the driving mechanism 300, the driving mechanism 300 can drive the push frame 200 to reciprocate back and forth, and the front part of the push frame 200 can pass between two adjacent heat preservation board supports 109 when the push frame 200 is reciprocating back and forth Clearance. Among them, such as Figure 4 As shown, the driving mechanism 300 includes a drive wheel 301, a left wheel set, a right wheel set and a transmission chain 302 that connects them together in transmission. The left wheel set is located at the top left of the drive wheel 301, and the right wheel set Located on the upper right of the driving wheel 301 , the driving wheel 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com