Efficient and oil-gas-free sealing device for floating roof storage tank

A floating roof storage tank and sealing device technology, applied in packaging, transportation and packaging, containers and other directions, can solve problems such as hidden safety hazards, oil and gas accumulation, secondary sealing collapse, etc., to ensure safe operation, tear resistance, The effect of soft indentation hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

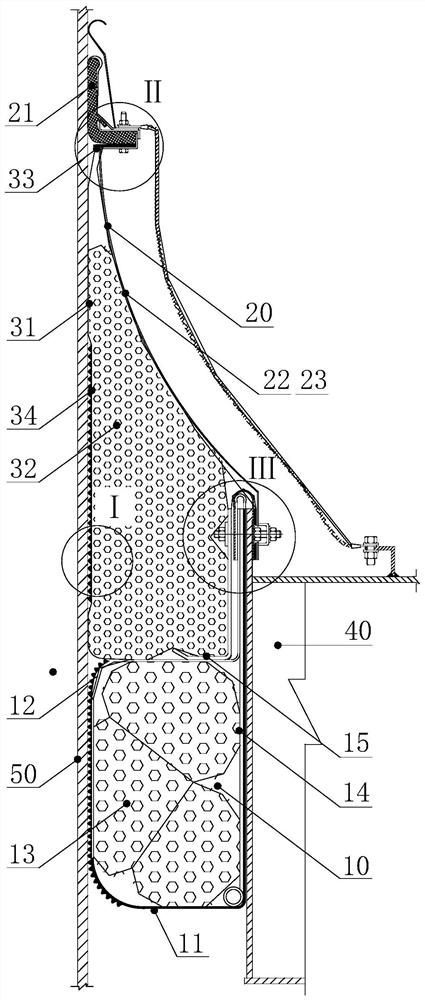

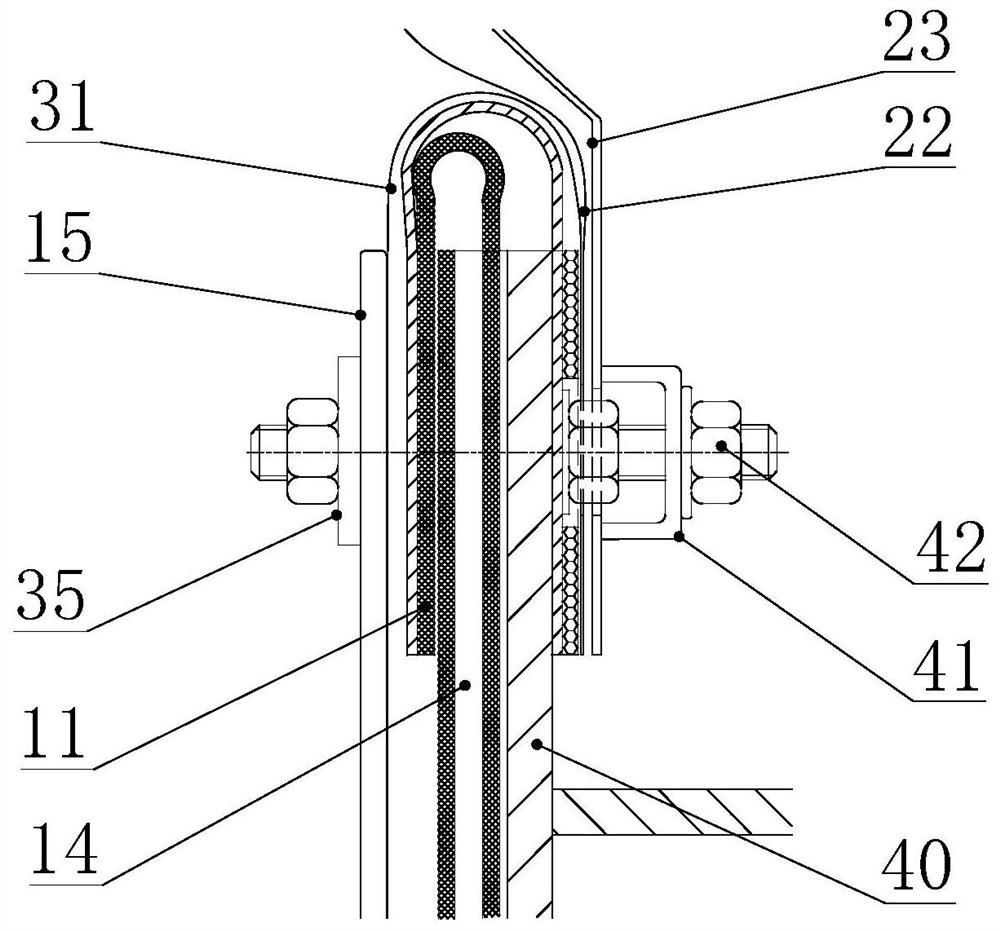

[0045] The specific structure of the present invention will be further described below in conjunction with the accompanying drawings.

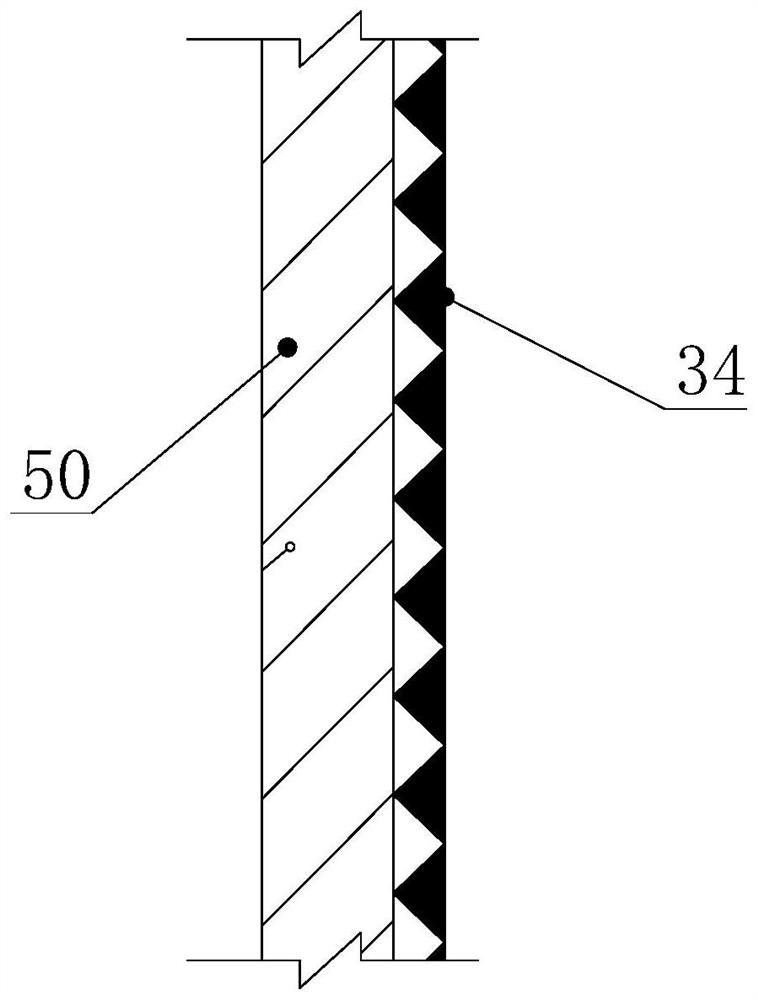

[0046] First of all, it should be noted that in this embodiment, the direction from the storage tank wall 50 to the edge plate 40 of the floating plate is defined as an inward direction, and the direction from the edge plate 40 of the floating plate to the wall 50 of the storage tank is defined as an inward direction. Therefore, the side of the tank wall 50 facing the edge plate 40 of the storage tank is the inner side of the tank wall, and the side of the edge plate 40 facing the tank wall 50 is the outer side of the edge plate of the floating plate. The side of the floating plate edge plate 40 away from the storage tank wall 50 is the inner surface of the floating plate edge plate.

[0047] Such as figure 1 As shown, a high-efficiency oil-free and gas-free sealing device for floating roof storage tanks, the device includes the following com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com