A dust-absorbing wall grinding system with adjustable grinding depth

A dust-absorbing and adjustable technology, which is applied to the parts of grinding machine tools, machine tools suitable for grinding workpiece planes, grinding machines, etc., can solve the problems of difficult to guarantee grinding accuracy, low construction efficiency, poor construction quality, etc., to achieve Effect of preventing dust spillage and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

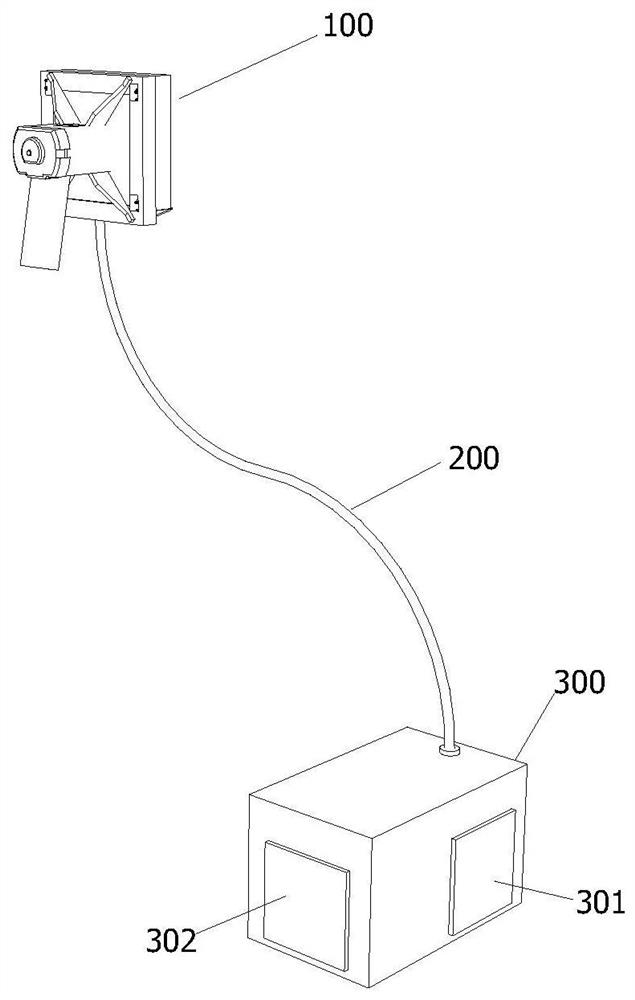

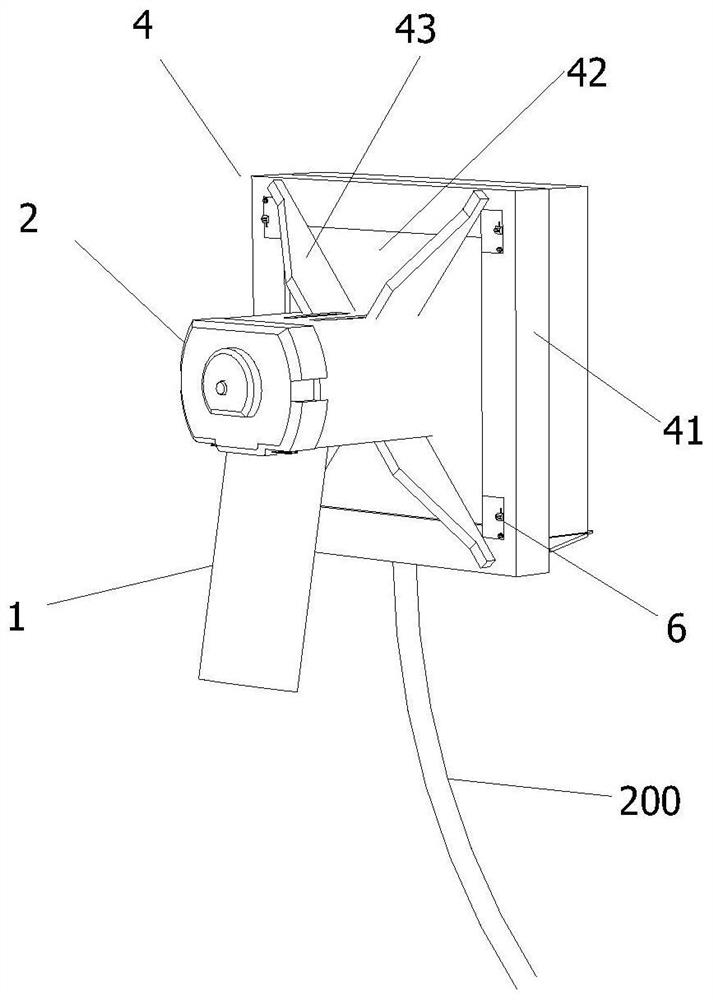

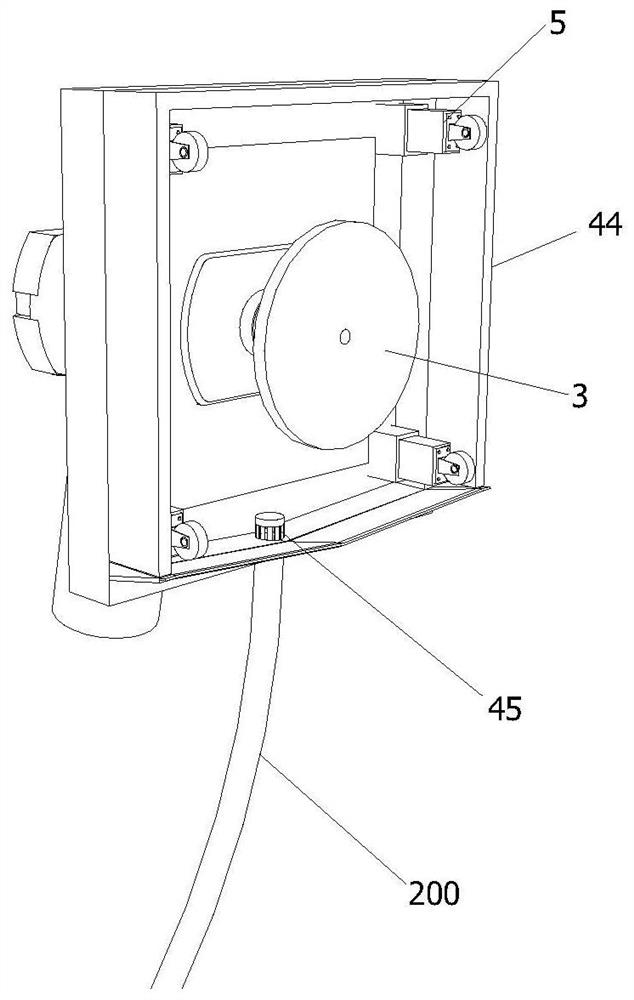

[0039] Such as figure 1 As shown, a vacuum wall grinding system with adjustable grinding depth provided in this embodiment includes a portable wall grinder 100 , a dust suction pipe 200 and a dust collection box 300 . combine figure 2 with image 3 As shown, the portable wall grinder 100 includes a handle 1 , a drive motor 2 , a grinding disc 3 , a dust cover 4 , several hydraulic buffer components 5 and a grinding depth adjustment component 6 . Can adopt prior art for holding handle 1, driving motor 2 and grinding cutter head 3, and its specific structure, connection relation and working principle are not described in detail. A dust collector is arranged in the dust collection box 300, and a dust discharge cabin door 301 and an exhaust grille 302 are arranged on the dust collection box. The dust collector can adopt the existing technology to suck the gas and dust in the dust cover 4 for dust collection. In the box 300, then the gas is discharged, and the dust is left in t...

Embodiment 2

[0050] This embodiment provides a construction method for accurately controlling the grinding depth of the wall surface. The dust-absorbing wall grinding system with adjustable grinding depth in Embodiment 1 is adopted. According to the following Figure 11 to Figure 13 , and combined with Figure 1 to Figure 10 Describe the construction method further. Described construction method comprises the steps:

[0051] Step 1. Determine the depth to be polished on the wall, adjust the position of the stepped limit card 61 through the adjustment button 62, and set all the grinding depth adjustment components 6 of the portable wall grinder to the required grinding depth;

[0052] Step two, such as Figure 11 As shown, start the portable wall grinder, start the vacuum cleaner, and gradually press the grinding cutter head to the wall 8 to grind out a circular groove, as shown in Figure 12 As shown, when the grinding depth reaches the maximum, the portable wall grinder is moved downwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com