Steel ball grinding scrap removing and screening device based on bearing internal assembly

A screening device and component technology, which is applied in grinding/polishing safety devices, sieves, solid separation, etc., can solve the problems of low working efficiency of the device and inability to completely remove waste debris, etc., and achieve convenient operation and improved The effect of screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

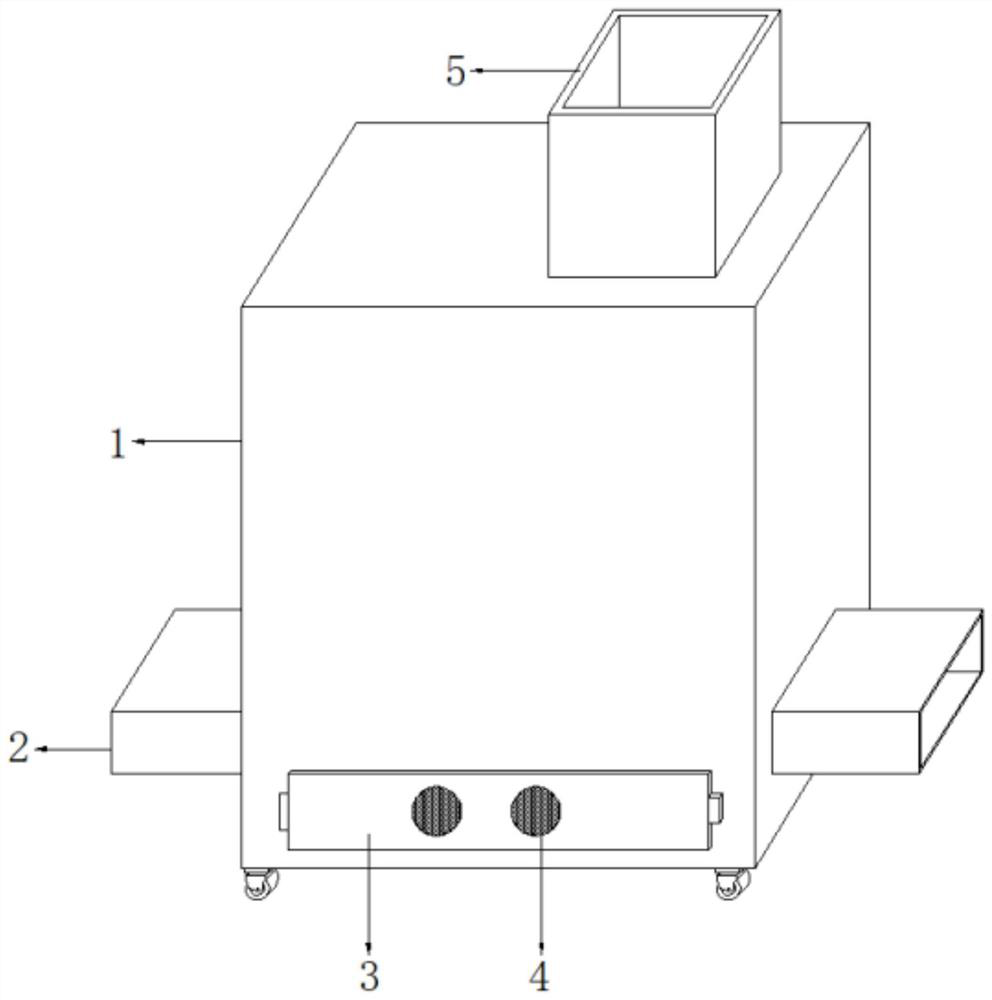

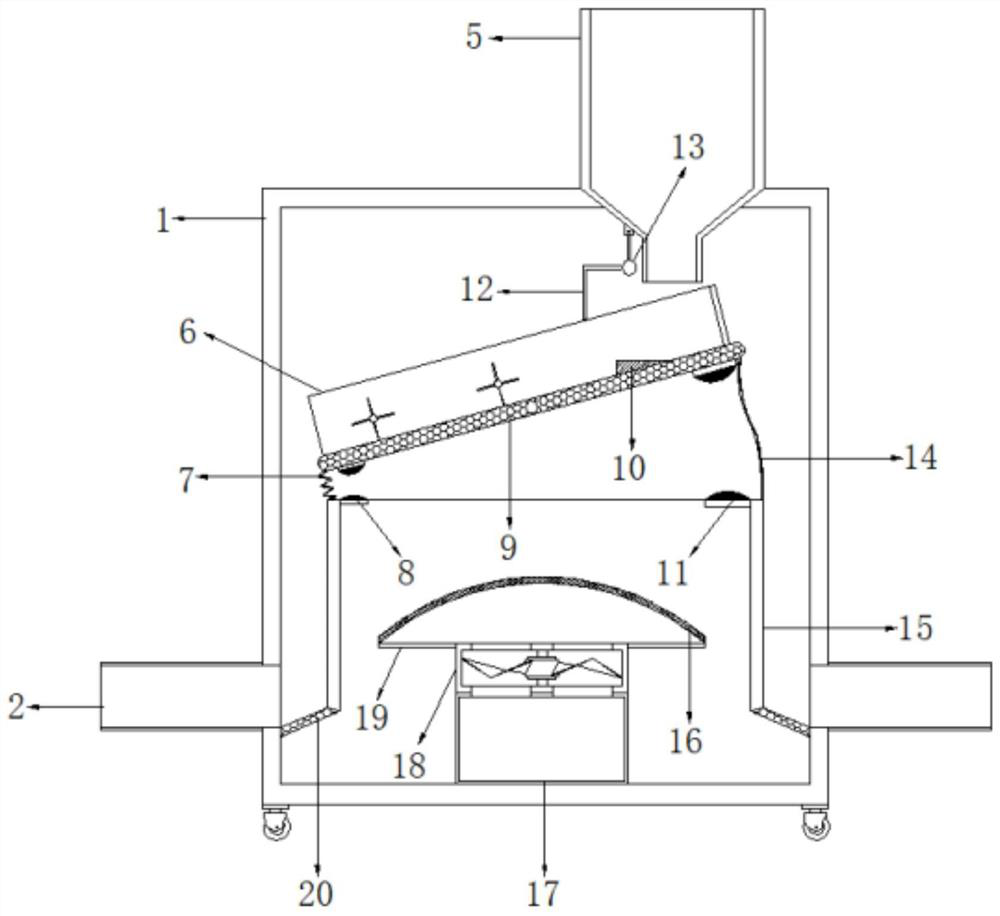

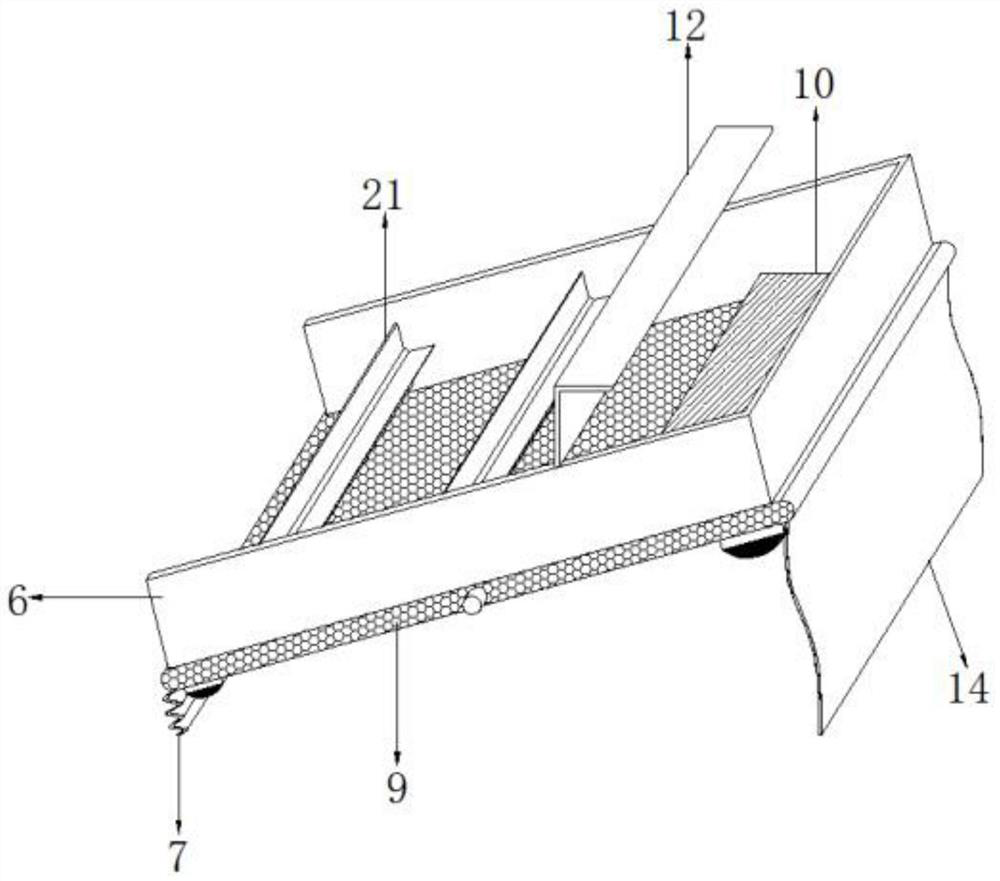

[0032] refer to Figure 1-5 , a steel ball grinding waste screening device based on the internal components of the bearing, including a treatment box 1, the top side of the treatment box 1 is connected with a feed hopper 5 by bolts, and the inner walls of the two sides of the treatment box 1 are close to the top The first screen cloth 9 is connected with the first screen cloth 9 by pin rotation between the middle position, and the two ends of the both sides inner walls near the bottom of the processing box 1 are welded with a baffle plate 15, and the top of one of the baffle plate 15 is connected with the first screen cloth 9 The first cloth bag 7 is fixedly connected between the bottom one end of the bottom, and the second cloth bag 14 is fixedly connected between the top of the other baffle plate 15 and the bottom other end of the first screen cloth 9, and one side top of one baffle plate 15 and One side of the bottom of the first screen 9 is welded with a first mount, and t...

Embodiment 2

[0041] refer to Figure 6-7 , a steel ball grinding based on the internal components of the bearing and a waste-removing screening device. Compared with Embodiment 1, the top of the first screen 9 is welded with blanking plates 24 distributed equidistantly, and the blanking The plate 24 is arranged in an S-shape.

[0042] Working principle: Since the blanking plate 24 is set in an S shape, when the steel balls and waste chips slide up and down the first screen 9, the S-shaped blanking plate 24 is used to increase the sliding distance of the steel balls, so that the waste chips can be fully through the first sieve 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com