Gas flow standard device with high and low pressure double calibration sections, and calibration method thereof

A gas flow, standard device technology, applied in test/calibration devices, measurement devices, liquid/fluid solid measurement, etc., can solve the problems of high cost and narrow calibration range, reduce construction costs, improve calibration accuracy, expand The effect of calibration capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

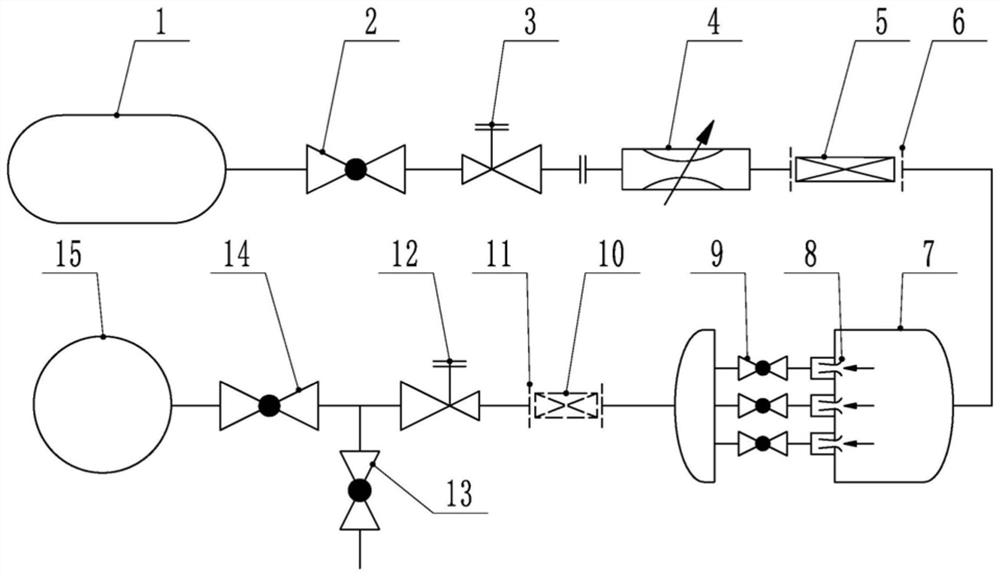

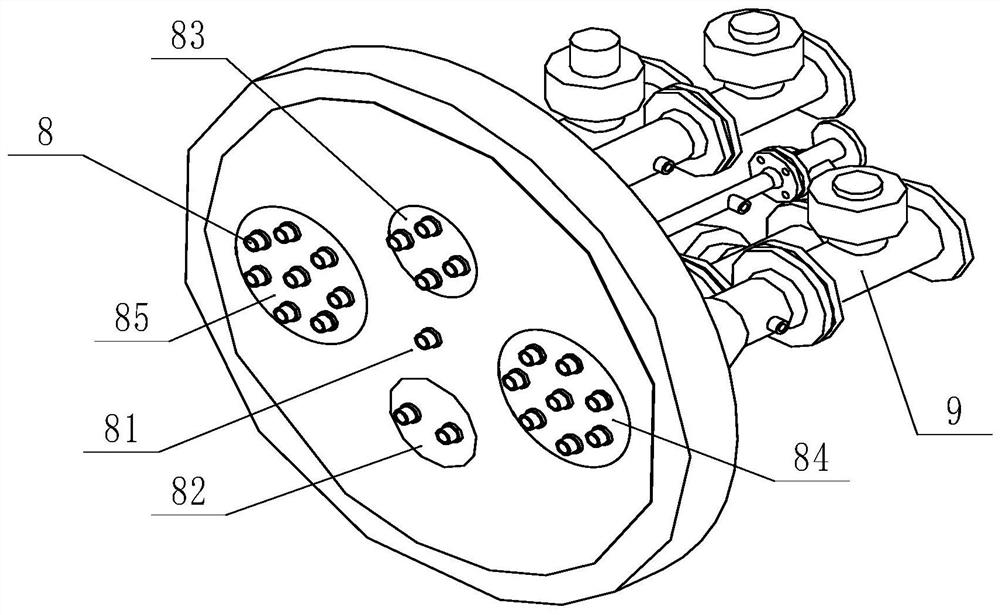

[0044] Combine figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 This embodiment will be described. In this embodiment, a gas flow standard device with high and low pressure dual calibration sections involved in this embodiment includes a high-pressure gas source 1, a high-pressure stop valve 2, a high-pressure regulating valve 3, and an adjustable Flow valve 4, high pressure calibrated flow meter 5, high pressure calibration section 6, stagnation vessel 7, critical flow sonic nozzle standard table 8, branch stop valve 9, low pressure calibrated flow meter 10, low pressure calibration section 11, low pressure regulating valve 12. Low-pressure exhaust valve 13, low-pressure shut-off valve 14, and vacuum source 15, the outlet of said high-pressure gas source 1 and high-pressure shut-off valve 2, high-pressure regulating valve 3, adjustable flow valve 4, high-pressure calibration section 6, stagnation The container 7, the low pressure calibration section 11, the low pressu...

Embodiment 2

[0049] This embodiment will be described in conjunction with Embodiment 1. In this embodiment, the calibration method of a gas flow standard device with high and low pressure dual calibration sections involved in this embodiment includes the following steps:

[0050] Step 1. Use the high pressure calibrated flow meter 5 to calibrate the critical state high pressure flow meter;

[0051] Step 2: Use the high-pressure calibrated flowmeter 5 to calibrate the non-critical state high-pressure flowmeter;

[0052] Step 3: Use the low-pressure calibrated flowmeter 10 to calibrate the low-pressure flowmeter.

[0053] A gas flow standard device and calibration method with high and low pressure dual calibration sections, which can be used for the calibration and verification of high-pressure working condition flowmeters and low-pressure working condition flowmeters. The total mass flow flowing through the standard meter can be passed through the following formula Calculation:

[0054]

[0055] Whe...

Embodiment 3

[0065] This embodiment will be described in conjunction with embodiment 1 and embodiment 2.

[0066] 1) When calibrating the critical state high pressure flow meter, the high pressure to be calibrated flow meter 5 is between the adjustable flow valve 4 and the stagnation vessel 7, and the actual state is similar Image 6 , The calibrated flow meter is located at section A2, the adjustable flow valve 4 is located at section A1, and the stagnation container 7 is the space in front of section A3. At this time P01> P02> P03, A1 k1, P01 / P03> k2, k1 and k2 are all a value greater than 1. The pipeline state set according to this area, as long as P01 is high enough, the calibrated flowmeter at section 2 can reach the critical state, that is, the throat reaches the speed of sound. That is to provide the ability to calibrate critical flow meters.

[0067] 2) When calibrating a non-critical state high pressure flow meter, the high pressure to be calibrated flow meter 5 is between the high pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com