An intelligent rubber tire hot film air-drying roller device

A rubber tire and pressure roller device technology, which is applied in the direction of drying gas arrangement, tire, drying, etc., can solve the problems of affecting the quality of thermal film, the inability to accurately control the extrusion pressure, uneven cross-section, etc., and achieve low drying cost , easy to disassemble and increase the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

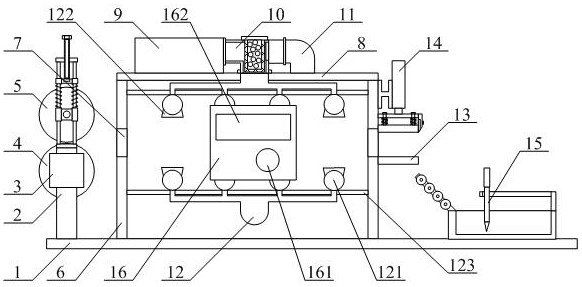

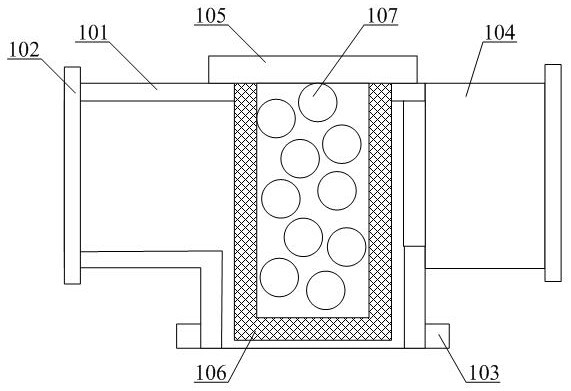

[0042] as attached figure 1 And attached figure 2 As shown, an intelligent rubber tire hot film air-drying roller device includes a bottom mounting base 1, a side mounting plate 2, a power motor 3, a fixed roller 4, an adjustable pressure movable roller structure 5, an air-drying box 6, and a feeding Port 7, upper mounting plate 8, fan 9, detachable drying and ventilation joint structure 10, aluminum foil ventilation pipe 11, four-port ventilation connecting pipe 12, fixed pressure plate 13, cutter mounting frame structure 14, thermal film collecting and discharging frame structure 15 and the control box 16, the side mounting plate 2 is respectively welded to the front and rear ends of the upper left side of the bottom mounting base 1; the power motor 3 is bolted to the upper front end of the side mounting plate 2; the fixed roll 4 is arranged on the upper part of the inner side of the side mounting plate 2, and is interference-connected with the output shaft of the power mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com