Device for achieving laser processing on surface of involute cylindrical gear

An involute cylinder, laser processing technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of keeping the groove depth and shape unchanged, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

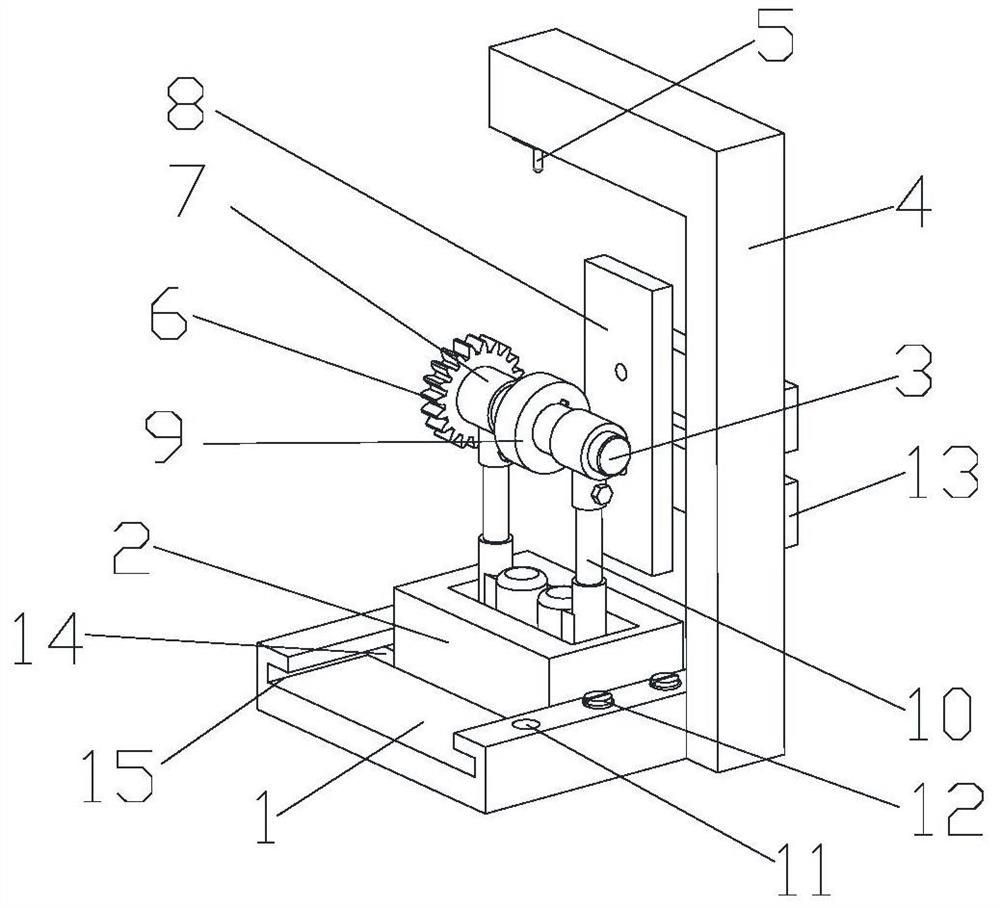

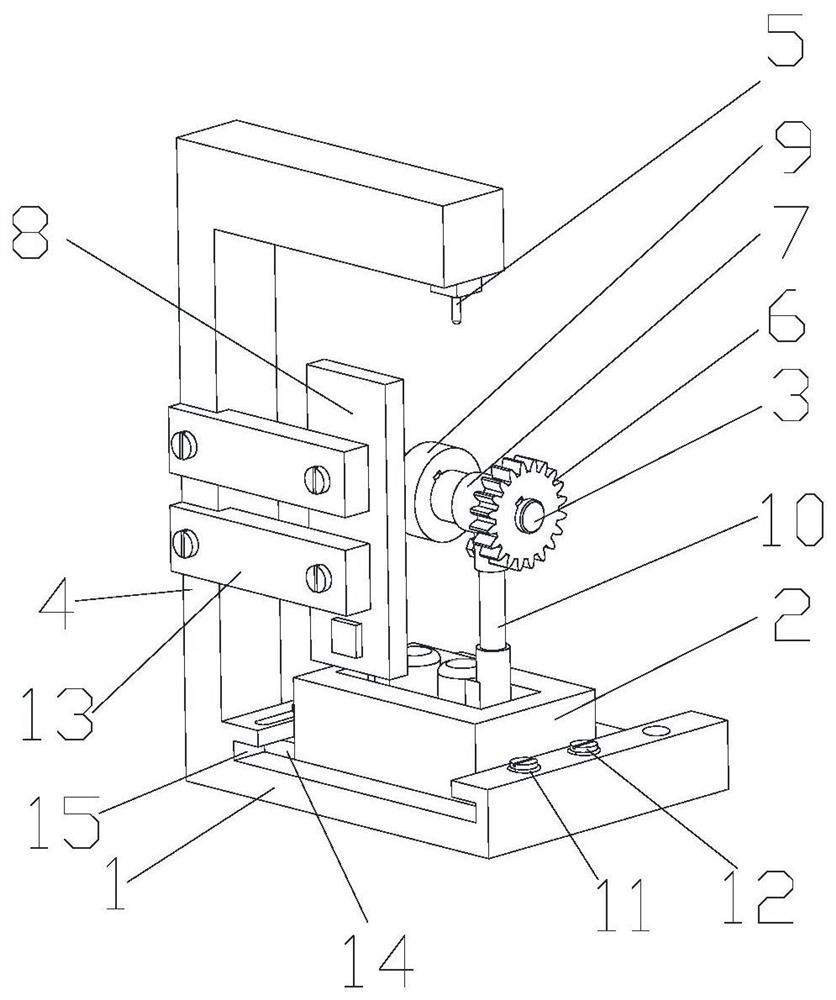

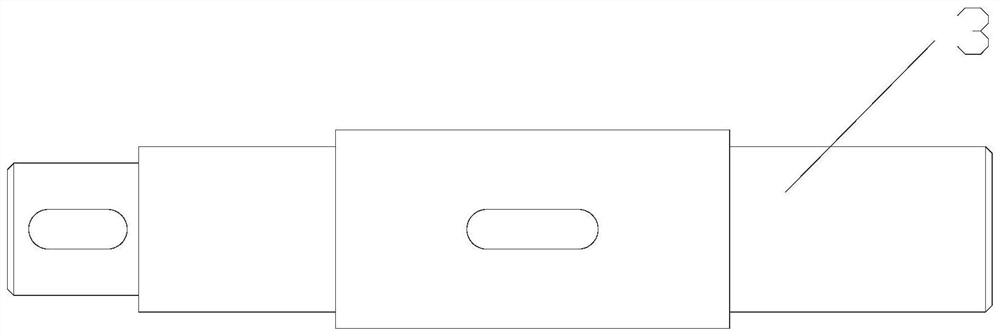

[0020] A device for laser processing the surface of an involute cylindrical gear, comprising a base 1, a slide table 2 slidably arranged on the base 1, an installation shaft 3 rotatably arranged on the slide table 2, and a fixed shaft installed on the base The laser marker 5 on one side of the base 1 and the electromagnetic chuck 8 fixedly arranged on one side of the base 1, the installation shaft 3 is used to install the gear 6, and the electromagnetic chuck 8 in this embodiment is perpendicular to the base 1 Setting as an example for illustration, the installation shaft 3 is fixed with a collar 9, the material of the collar 9 is iron, which is convenient to be absorbed by the electromagnetic chuck 8, and the outer diameter of the collar 9 is consistent with the base circle of the gear 6 The diameters are consistent. In order to prevent the gear 6 from interfering with the electromagnetic chuck 8, the gear 6 is located outside the electromagnetic chuck 8, and the slide table 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com