Peculiar smell removing equipment

A technology for odor removal and equipment, which is applied in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, and can solve problems such as the weakening of the filtering effect of the filter cotton layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

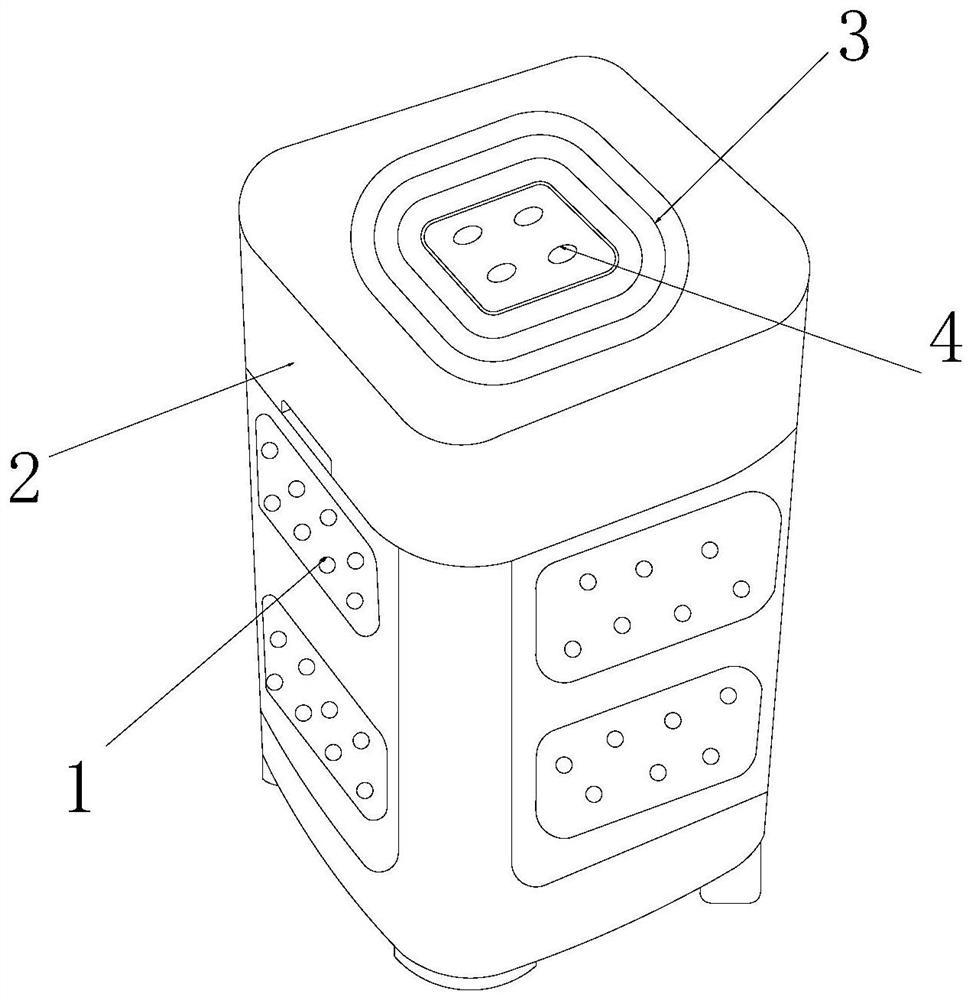

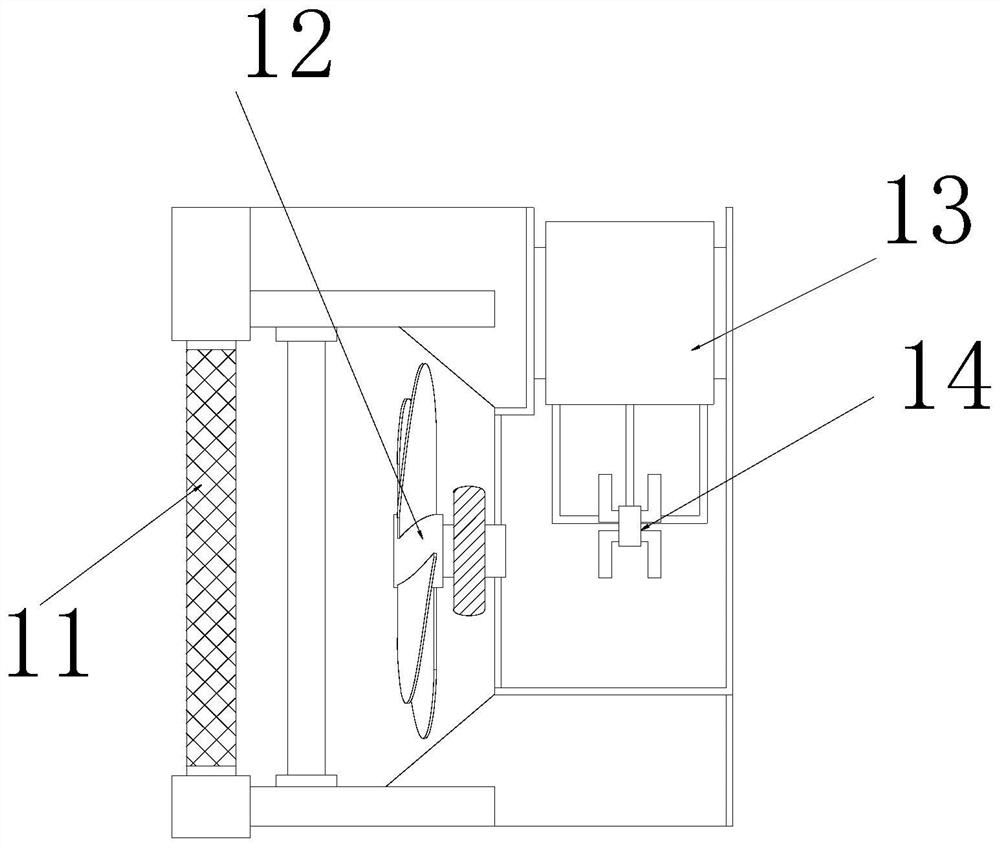

[0025] as attached figure 1 To attach Figure 4 Shown:

[0026] The present invention provides a kind of peculiar smell removing equipment, its structure comprises filter system 1, equipment box 2, vent hole 3, central control panel 4, and described filter system 1 is embedded and installed on the outer end surface of equipment box 2, and described equipment box 2 The air outlet 3 is inlaid and engaged with the upper end surface of the air outlet 3, and the air outlet 3 is embedded and installed directly above the filter system 1, and the central control panel 4 is located at the center of the upper end surface of the air outlet 3; the filter system 1 includes Filter screen plate 11, impeller 12, filter core 13, vibration mechanism 14, the filter screen plate 11 is inlaid and installed on the left side of the impeller 12, the impeller 12 is movably mounted on the inner end surface of the filter system 1, the filter core 13 is embedded and installed on the inner end surface o...

Embodiment 2

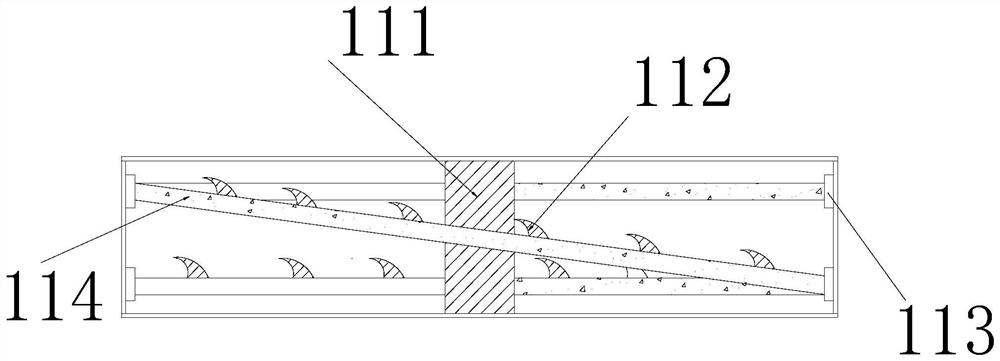

[0032] as attached Figure 5 To attach Figure 7 As shown: the vibration mechanism 14 includes a vibrating rod 141, a vibrating ring 142, a rotating blade 143, and a clamping ring 144. The vibrating rod 141 is inlaid and installed on the outer end face of the vibrating ring 142, and the outer end face of the vibrating ring 142 is evenly inlaid The rotating blade 143 is engaged and connected, and the rotating blade 143 is symmetrically installed on the left and right sides of the outer end surface of the vibrating ring 142. The clamping ring 144 is installed on the upper end surface of the vibrating rod 141 by welding, and the vibrating rod 141 is provided with Four of them are evenly engaged and connected to the filter element 13 in a ring shape, which can effectively transmit the vibration brought by the vibration ring 142 .

[0033] Wherein, the vibrating ring 142 includes a toggle block 421, a fixed ring 422, a vibrating block 423, a connecting rod 424, and a conductive bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com