Permanent magnet motor assembling jig and method thereof

A permanent magnet motor and assembly jig technology, applied in the direction of centering/balancing the rotor, etc., can solve the problems of assembly process obstruction and inability to complete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

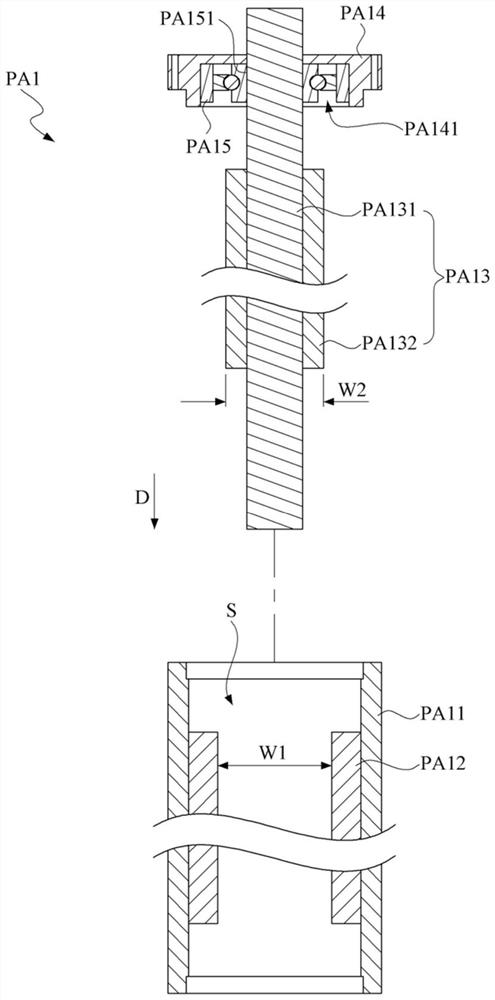

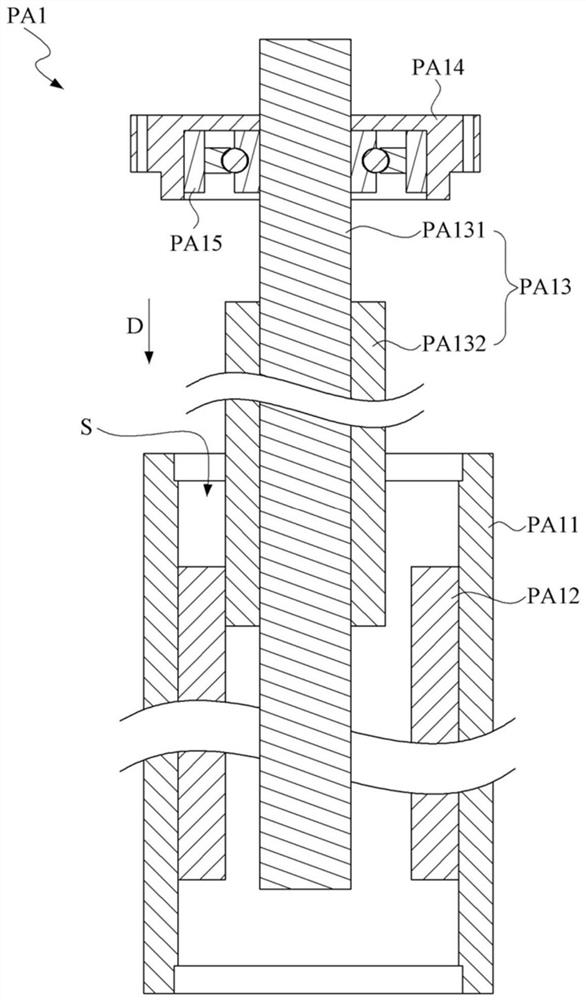

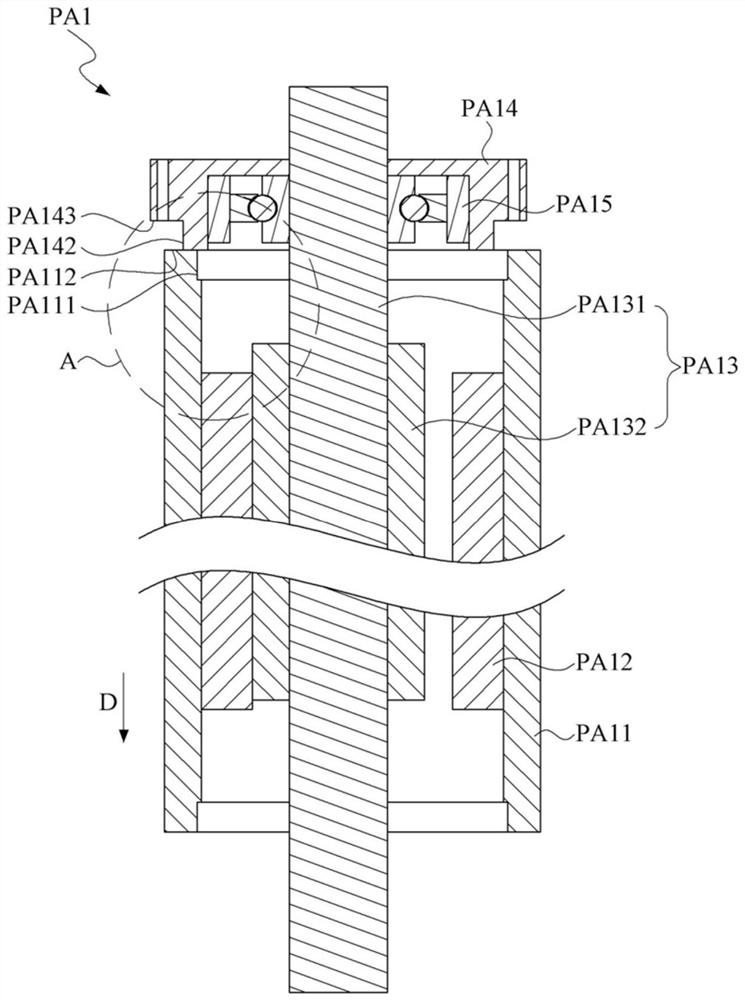

[0095] see Figure 5 to Figure 7 ,in, Figure 5 A perspective view showing the permanent magnet motor assembly jig provided by the preferred embodiment of the present invention; Figure 6 A three-dimensional combined view showing the guide tube and the fixed platform of the permanent magnet motor assembly jig provided by the preferred embodiment of the present invention; and, Figure 7 show Figure 6 The A─A sectional view. As shown in the figure, a permanent magnet motor assembly jig 1 is used to assemble a permanent magnet motor 2 (marked on Figure 12 ), including a fixed platform 11 , a guide tube 12 and a guide shaft 13 .

[0096] The fixing platform 11 includes a carrying component 111 and a fixing component 112 , and defines a through hole H. As shown in FIG. The carrying component 111 and the fixing component 112 include a carrying plate 1111 and a supporting member 1112 . The supporting plate 1111 is provided with the aforementioned through hole H and has a supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com