Intercooling humidifying device and fuel cell system applying same

A humidification device and heat exchange device technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange and other directions, can solve the problems of complex layout, increased pipeline flow resistance, large space occupation, etc., to increase the mutual contact area , the effect of increasing airflow capacity and improving overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

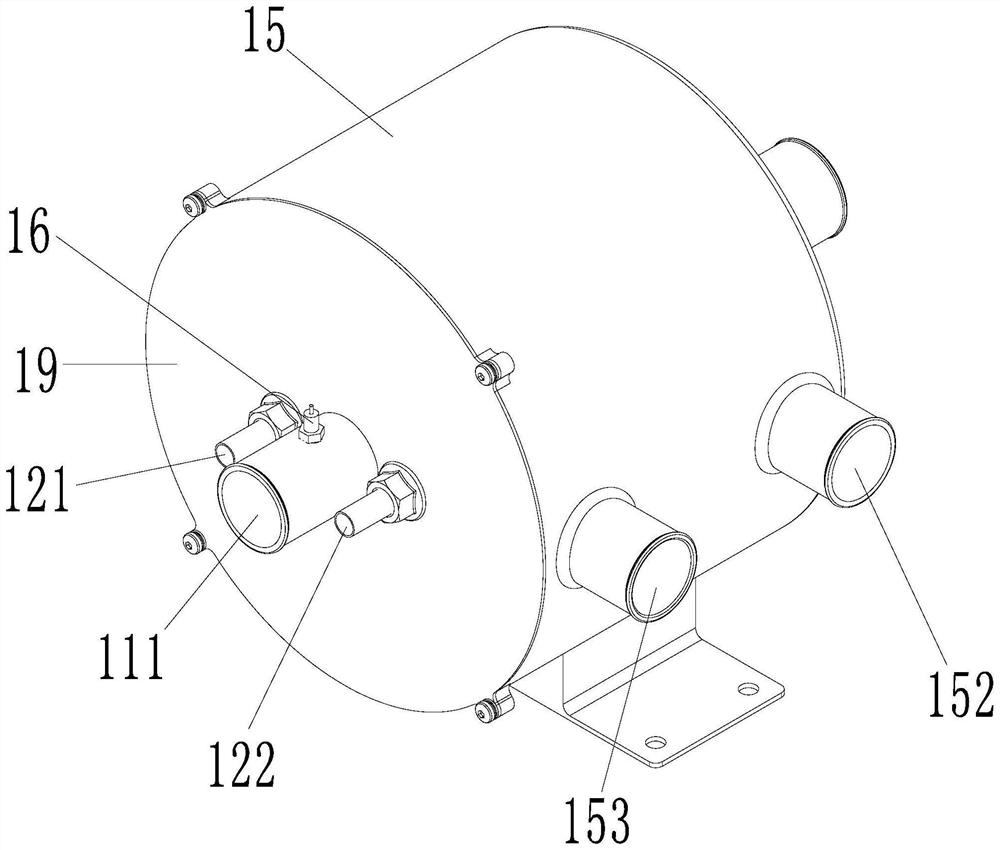

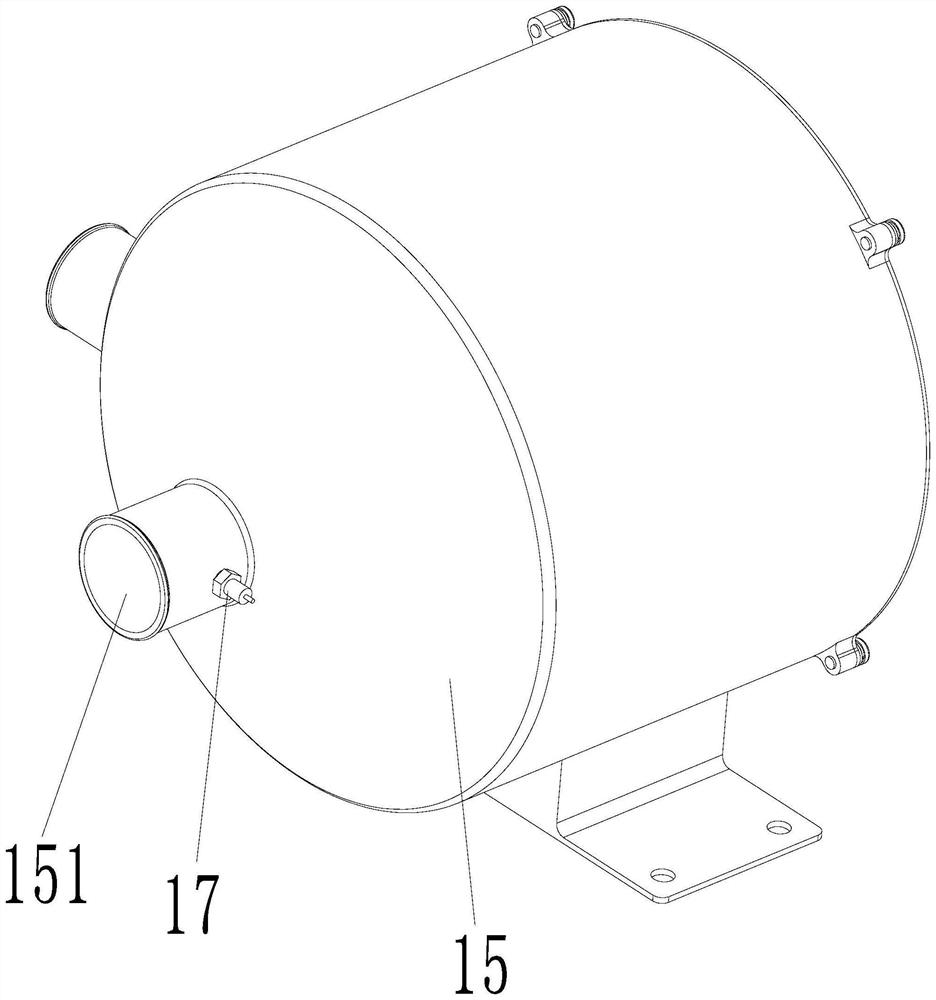

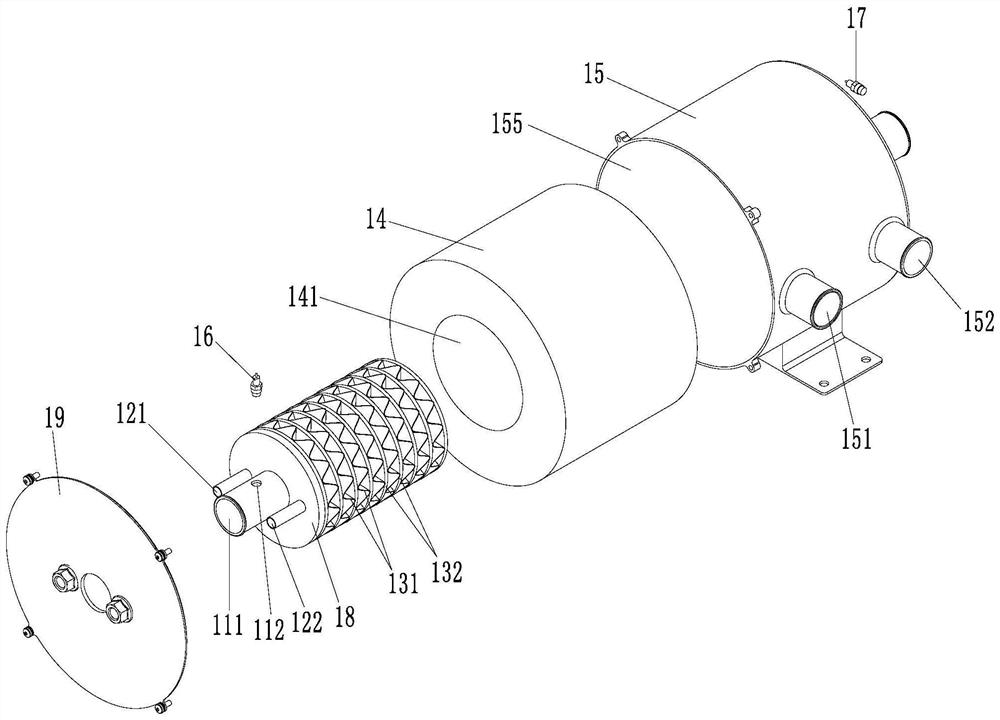

[0044] Such as Figure 1 to Figure 15As shown, this embodiment provides an intercooling and humidifying device, which is characterized in that it includes an air intake pipe 11, a heat exchange device 13, a humidification module 14 and a sleeve shell 15, and the heat exchange device 13 is set on the air intake pipe 11, the humidification module 14 is set outside the heat exchange device 13, the sleeve shell 15 is set outside the humidification module 14, and one end of the sleeve shell 15 is provided with a first air outlet 151, and the dry hot air flows from the air intake duct 11 One end enters and flows out radially, and after the cooling treatment of the heat exchange device 13 and the humidification treatment of the humidification module 14, the humid air formed at a low temperature flows out from the first air outlet 151. This structure will intercool and humidify the The function is integrated, the structure is simple and compact, occupies less space in the overall layo...

Embodiment 2

[0060] Such as Figure 16 with Figure 17 As shown, a fuel cell system includes a fuel cell stack module, a fuel cell system controller, a coolant circulation system, an air intake system, a hydrogen supply system, and an intercooling and humidifying device, and the air intake system includes an air filter , an air flow meter and an air compressor, characterized in that: the intercooling and humidifying device is the intercooling and humidifying device described in any one of claims 1 to 11, and the air enters the air after passing through the air filter and the air flow meter. Compressor, the air compressor controller controls the air compressor to compress the incoming air from the first air inlet 111 of the intercooling and humidifying device to enter through the heat exchange device 13 to exchange heat between the air and the cooling liquid, and then enter The humidification module 14 humidifies the passing air and discharges it from the first air outlet 151, and then inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com