Device for evaluating filtration performance of drilling fluid on line

A drilling fluid and fluid loss technology, applied in measuring devices, liquid/fluid solids measurement, instruments, etc., can solve the problems of many operation steps, large sample volume, long time consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

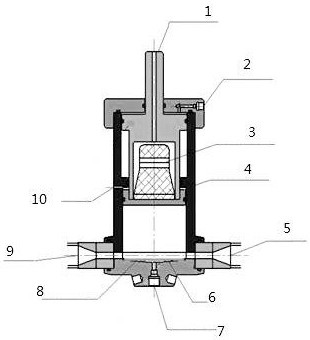

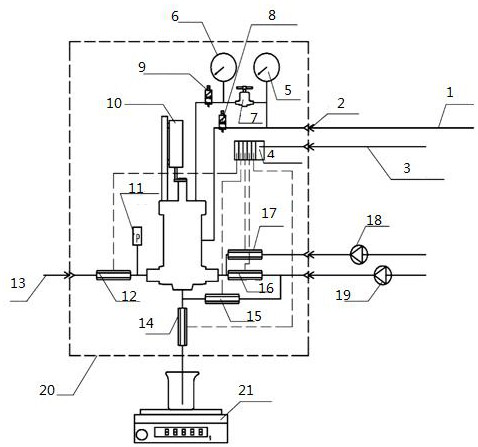

[0040] Embodiment 1: The fluid loss body is made of stainless steel with a pressure resistance of 1.5 MPa. A displacement sensor is installed on the top, the stroke of the piston is 50mm, the ultrasonic generator is installed in the piston, and there is a filter medium at the bottom to filter impurities, and the filtered liquid flows out through the bottom port. On both sides of the main body, there are interfaces for connecting the clean water pump, mud pump and venting. The filter loss medium uses a repeatable 316L laser hole plate instead of filter paper and cooperates with an ultrasonic washing device to realize the repeated application of the filter loss medium; the holes on the filter loss medium are circular and evenly distributed, and the thickness of the medium is 1mm. The compression spring presses the filtered fluid loss medium and guides the liquid through the radiation groove at the bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com