Pump base of lubricating pump and lubricating pump

A technology for lubricating pumps and pump bases, used in lubrication pumps, lubricating parts, engine lubrication, etc., can solve problems such as low exhaust efficiency, and achieve the effect of improving exhaust efficiency and reducing air content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0031] The specific embodiment of lubricating pump of the present invention:

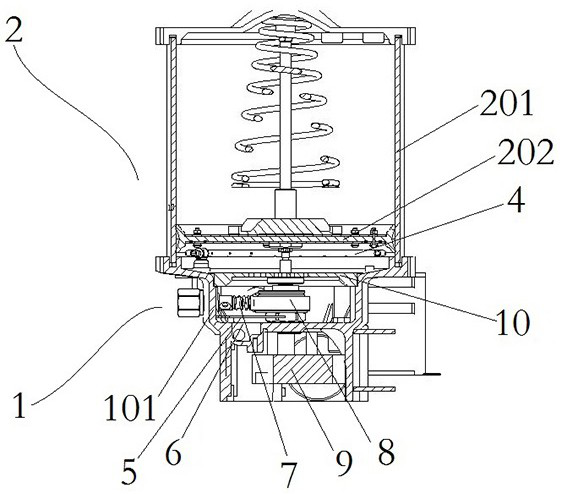

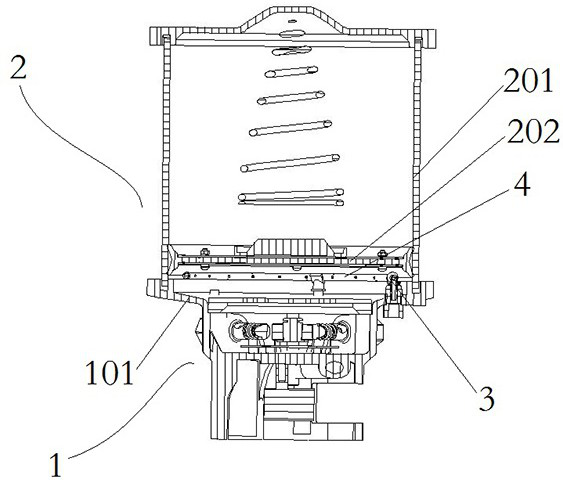

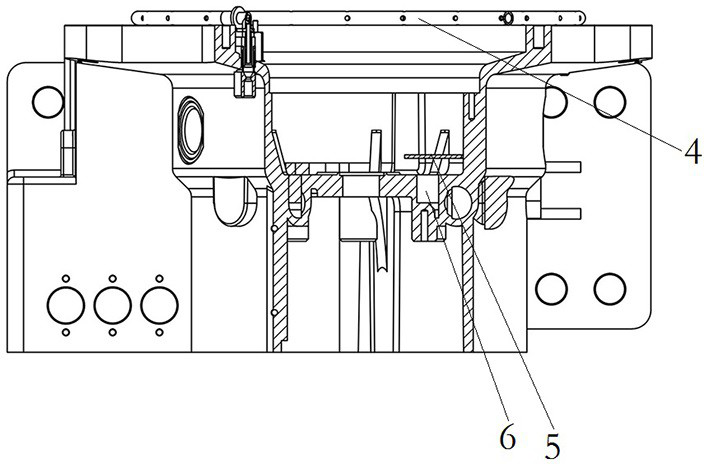

[0032] Such as Figure 1 to Figure 6 As shown, the lubricating pump includes a lubricating pump base 1 and an oil tank 2 fixed on the lubricating pump base 1. The upper side of the lubricating pump base 1 has a base 101, and the base 101 and the oil tank 2 form a sealed oil chamber. The bottom of the seat body 101 is provided with an oil filling port 6 communicating with the oil chamber for filling oil into the oil chamber.

[0033] The base body 101 is also provided with a horizontal deflector 5, the deflector 5 covers the top of the oil filling port 6, and the deflector 5 is spaced from the bottom wall of the base 101 to form a flow guide channel for the grease to spread horizontally. . The base body 101 is provided with an exhaust passage communicating with the outside w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com