A high stability high pressure fire pump

A high-stability, fire-fighting pump technology, applied to pumps, parts of pumping devices for elastic fluids, pump components, etc., can solve problems such as reduction, reduce cumbersomeness, increase contact area, and reduce potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

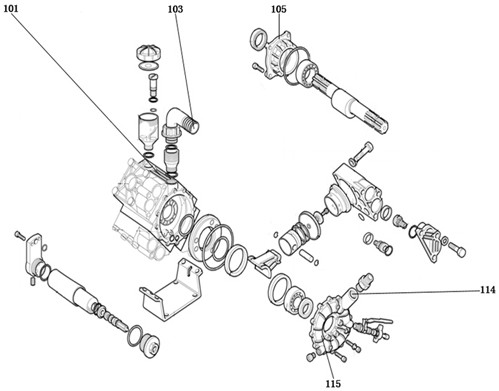

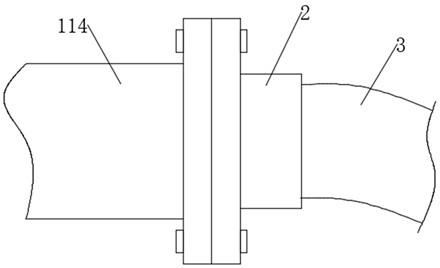

[0040] see figure 1 , a high-stability high-pressure fire pump, including a front cover 105, a pump casing 101, a drive mechanism, a booster mechanism, and a water outlet pool 115, the outer end of the water outlet pool 115 is fixedly connected to a water outlet 114, and the water outlet of the water outlet 114 Bolted with mounting disc 2 .

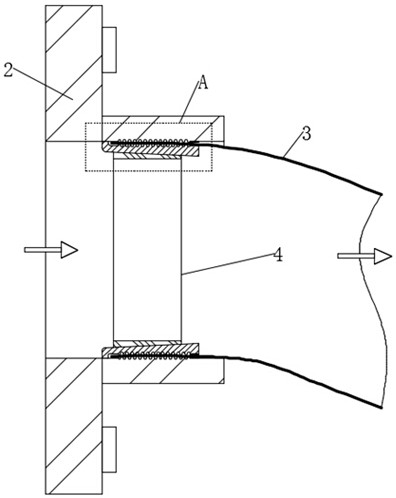

[0041] see Figure 2-4 , the end of the mounting plate 2 away from the water outlet 114 is provided with a water pipe 3, the inner wall of the mounting plate 2 is fixedly connected with a sawtooth snap ring 5, and the inside of the serrated snap ring 5 is fitted with a wedge-shaped embedded ring 4, and the inner wall of the installation plate 2 and the serrated snap ring The ends of the rings 5 that are close to each other are respectively provided with an undulating fixed layer 61 and an undulating dynamic layer 62. The undulating fixed layer 61 and the undulating dynamic layer 62 are matched with each other, and the two are not in co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com