Process for manufacturing intelligent security door

An intelligent anti-theft door and manufacturing process technology, applied in the field of intelligent anti-theft door manufacturing technology, can solve the problems of high cost and difficulty in popularization of anti-theft doors, and achieve the effects of good plasticity, reduced total cost, and strong temperature adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

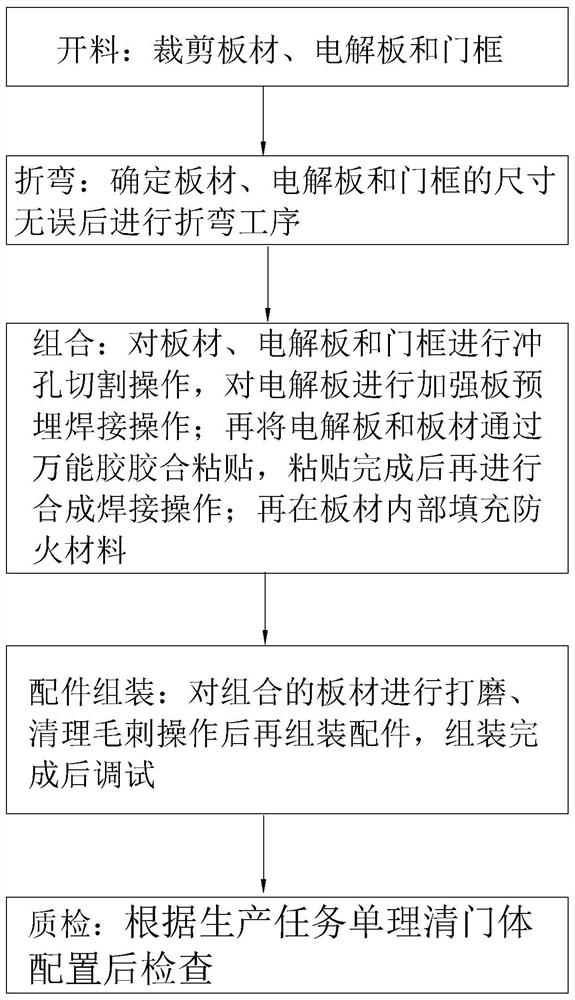

[0046] The following is attached figure 1 The application is described in further detail.

[0047] The embodiment of the present application discloses a manufacturing process of an intelligent anti-theft door. refer to figure 1 , the manufacturing process of the anti-theft door comprises the following steps:

[0048] 1) Cutting: cutting plates, electrolytic plates and door frames. In this example, the surfaces of the selected plates, electrolytic plates and door frames need to be smooth and flat, free of orange peel, cracks, sagging, and color difference, etc., and the plates and electrolytic plates that need to be cut are calculated according to the size required by the customer. Cut to the size of the door frame. Among them, the material of the plate is stainless steel plate, and the electrolytic plate is made of steel plate through electrolytic treatment. The area of the electrolytic plate is the same as that of the plate. The sum of the thickness of the electrolytic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com