A kind of organic-inorganic electric polarization particle and its preparation method and application

An electro-polarized and inorganic technology, applied in instruments, optics, nonlinear optics, etc., can solve the problems of unsatisfactory minimum transmittance, complex processing technology, and limited application scenarios of smart glass technology, and achieve a wide range of color adjustment. , Simple preparation, wide color change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The preparation method of the titanium oxide nanorod solution includes: adding 2.4 g of titanium sulfate and 6.7 g of citric acid into 14 mL of deionized water, and ultrasonically dispersing and dissolving. Add 8 mL of ethylenediamine, stir for 1 hour, transfer to a 50 mL hydrothermal reaction kettle, and react at 200° C. for 6 h. The resulting precipitate was washed three more times with deionized water to yield about 1.1 g of wet titanium oxide product. Take 500 mg of it and add 100 mL of ethylene glycol methyl ether, remove part of the water and then ultrasonically disperse for 3 hours. Its concentration was determined to be 3.0 mg / mL by heating method.

[0063] The homemade method of polyoctyl methacrylate (Mn=4300) is: add 15.2g butyl methacrylate and 10.5g acryloxypropyltrimethoxysilane to 125mL ethyl acetate, add 175mg AIBN, remove oxygen, The temperature was raised to 75°C for 4h. Cool down to 60° C. and add 0.5 g of triethylene glycol dimethacrylate to carry...

Embodiment 1

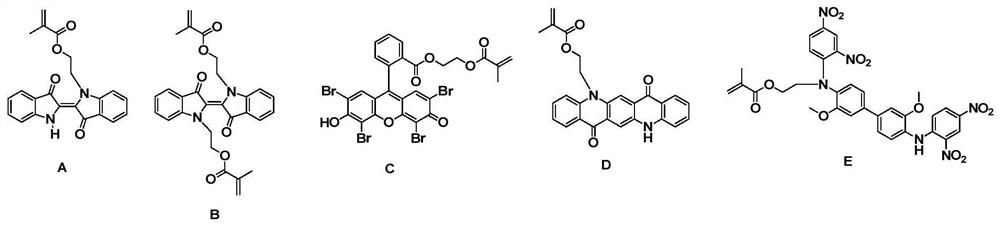

[0066] 1) Prepare dye molecule A according to literature [ACS Appl.Mater.Interfaces 2013,5,7086]: add 2.6g of indigo raw material (CAS: 482-89-3; Tokyo Chemical Co., Ltd.) into a 100mL single-necked round bottom flask, Add 4.1 g of ethyl 2-chloromethacrylate (Alpha Aesar Chemical Co., Ltd., 98%), 2.5 g of potassium carbonate (analytical grade) and 50 mL of N,N-dimethylformamide to dissolve it. Subsequently, the temperature of the reaction solution was raised to 110° C., and nitrogen gas was passed for 15 minutes. After 12 hours of reaction, the temperature was lowered, and 100 mL of deionized water was added to precipitate a blue blocky solid. Then the blue solid was collected, 120 mL of dichloromethane was added, stirred for 30 minutes, and the insoluble matter was removed. The crude product was recrystallized in a mixed solvent of petroleum ether:dichloromethane=2:1 to obtain 2.0 g of solid powder dye molecule A with a yield of 76%.

[0067]

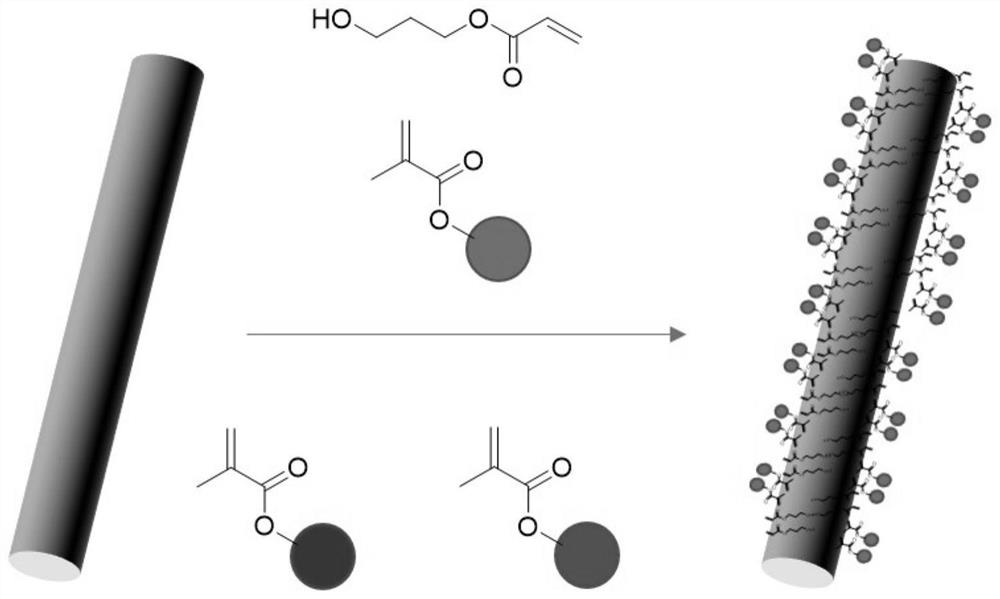

[0068] 2) if figure 2 As...

Embodiment 2

[0073] 1) Preparation of organic-inorganic electrically polarized particles: Add dye molecule A (75.0mg), hydroxypropyl acrylate (178.0 mg), ventilated for 15 minutes. Add AIBN2.3mg (dissolved in 1mL tetrahydrofuran), and react at 75°C for 4h. Continue to heat up to 85 degrees, after 1h of reaction. The reaction solution was concentrated to 10 mL, poured into 100 mL of n-hexane, and a dark blue powder solid was precipitated, washed twice with n-hexane and then once with ethanol, and the obtained solid was blown dry with nitrogen for later use.

[0074] 2) Disperse about 100 mg of the blue solid powder from the previous step in ethyl acetate (15 mL), add 270 mg of polyoctyl methacrylate (Mn=4300, self-made), stir at high speed for 2 hours, and remove the ethyl acetate in vacuo to obtain a blue color slurry. Mix the above blue slurry with 1.7mL cross-linkable polystyrene solution (dichloromethane solution, concentration 200mg / mL, Mn=4400, self-made), add photoinitiator 907 (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com