A general electrode coating system for lithium/sodium ion batteries

A sodium-ion battery, general-purpose electrode technology, applied in battery electrodes, electrode collector coatings, secondary batteries, etc., to achieve the effect of ensuring stability, reducing friction, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

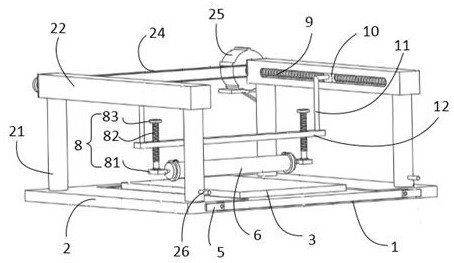

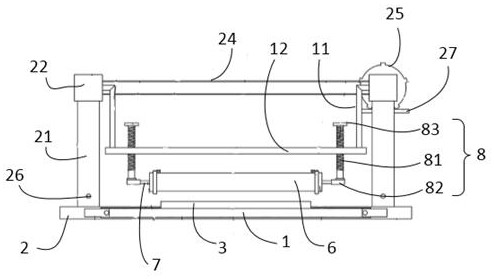

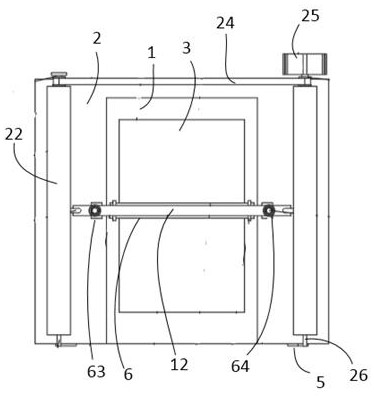

[0041] Embodiment 1: see Figure 1 to Figure 13 , a general electrode coating system for lithium / sodium ion batteries, including a base plate 2, a slot is provided on the upper side of the base plate 2, and the slot runs through the front side of the base plate 2, thereby forming a socket on the front side of the base plate 2. A support plate 1 is provided in the slot, and a positioning groove for installing the base 3 is provided on the upper side of the support plate 1; Board 1 can move back and forth along the slot. A buffer device 4 is provided between the back side of the support plate 1 and the back side of the slot. Two compression devices 5 are arranged on the front side of the base plate 2, and the compression devices 5 are distributed on both sides of the slot, and are rotatably connected with the base plate 2, and the rotation of the compression devices 5 can make the compression devices 5 and the support plate 1 contact with the front side, and can cooperate with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com