Automatic coupling probe for ultrasonic department

An automatic coupling, ultrasonic technology, used in ultrasonic/sonic/infrasonic diagnosis, medical science, sonic diagnosis, etc., can solve the problems of inconvenient and quick disassembly, cumbersome disassembly, easy damage, etc., to prevent accumulation of dust and adjust operation. Simple and effective to meet the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

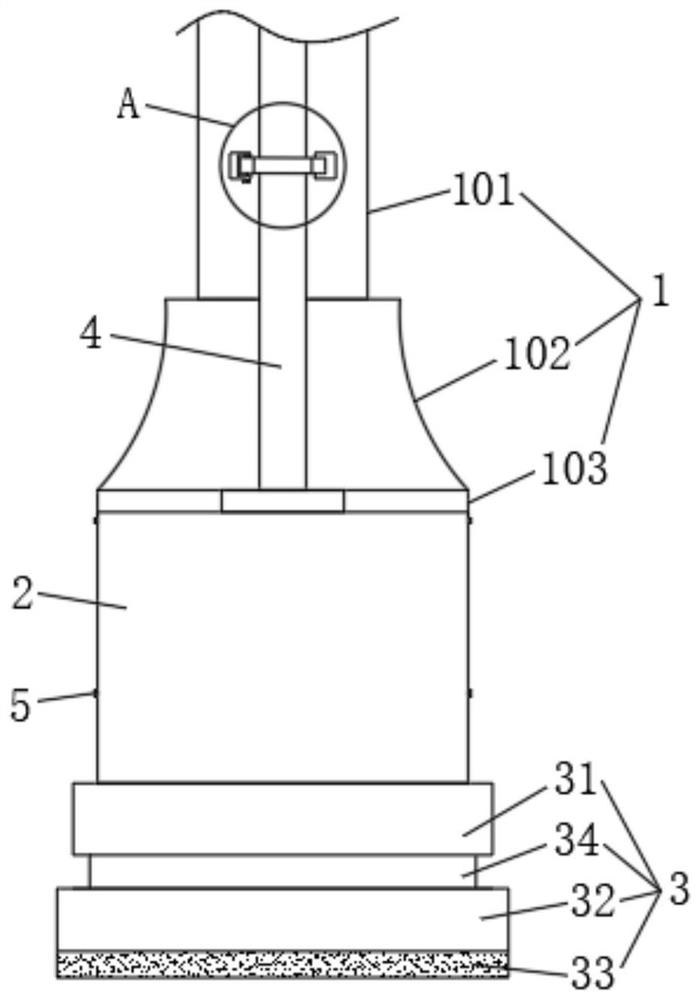

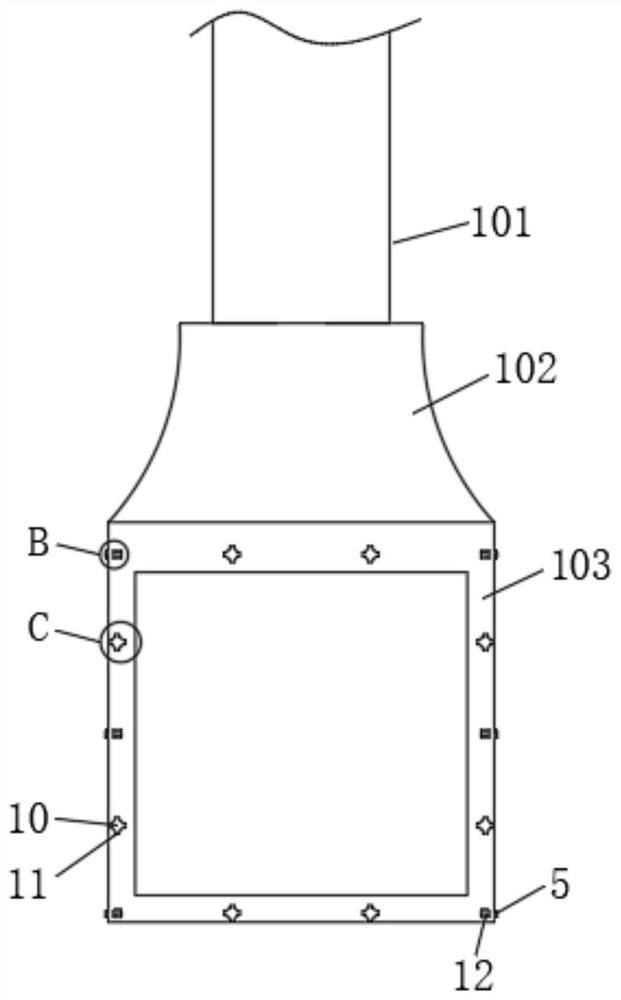

[0042] see Figure 1-Figure 15 shown, where figure 1 It is a schematic structural diagram of an ultrasonic automatic coupling probe provided by an embodiment of the present invention. It can be seen from the figure that the automatic coupling probe includes a detection component, a protection mechanism 3 sleeved at the end of the detection component, and a connection between the detection component and The matching component of the protection mechanism 3, the detection component includes the probe body 1 and the automatic coupling mechanism 2 clamped by the connecting component, and the automatic coupling mechanism 2 is clamped at the bottom of the probe body 1;

[0043] The protection mechanism 3 includes an outer frame 31 and a sleeve frame 32 sleeved on the end of the outer frame 31. The outer frame 31 is provided with a movable groove 34, and the edge of one end of the sleeve frame 32 extends inward to form a movable part 35, and the movable part 35 It fits inside the mov...

Embodiment 2

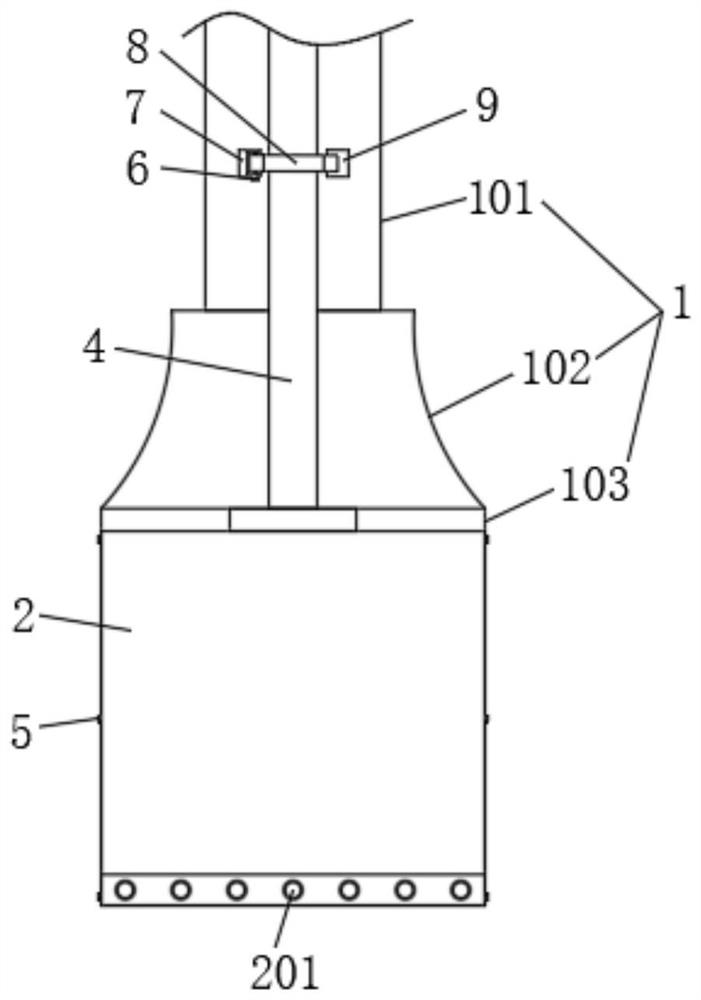

[0067] see Figure 15As shown, the mating assembly includes installation holes opened on both sides of the probe body 1 and the automatic coupling mechanism 2, and insertion rods 21 symmetrically screwed to both sides of the protection mechanism 3. The insertion rods 21 penetrate the interior of the installation holes, and the insertion rods 21 A twisting rod is installed at one end outside the protection mechanism 3 , and there are at least four mounting holes and inserting rods 21 , and the four inserting rods 21 correspond to the four mounting holes one by one.

[0068] Specifically, in this implementation, when it is necessary to use the probe, the medical staff can first screw the insertion rod 21 through the screw rod to unscrew the insertion rod 21 from the mounting hole, and then pull the protection mechanism 3 to release the protection mechanism 3 from the probe. The body 1 and the outer part of the automatic coupling mechanism 2 are removed, and then the medical pers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com