Novel high-efficiency composite permanent magnet motor Halbch iron core structure

A permanent magnet motor, iron core structure technology, applied in the shape/style/structure of magnetic circuit, synchronous motor with static armature and rotating magnet, magnetic circuit, etc., to simplify the control mode of the frequency converter, improve the output performance, The effect of reducing harmonic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

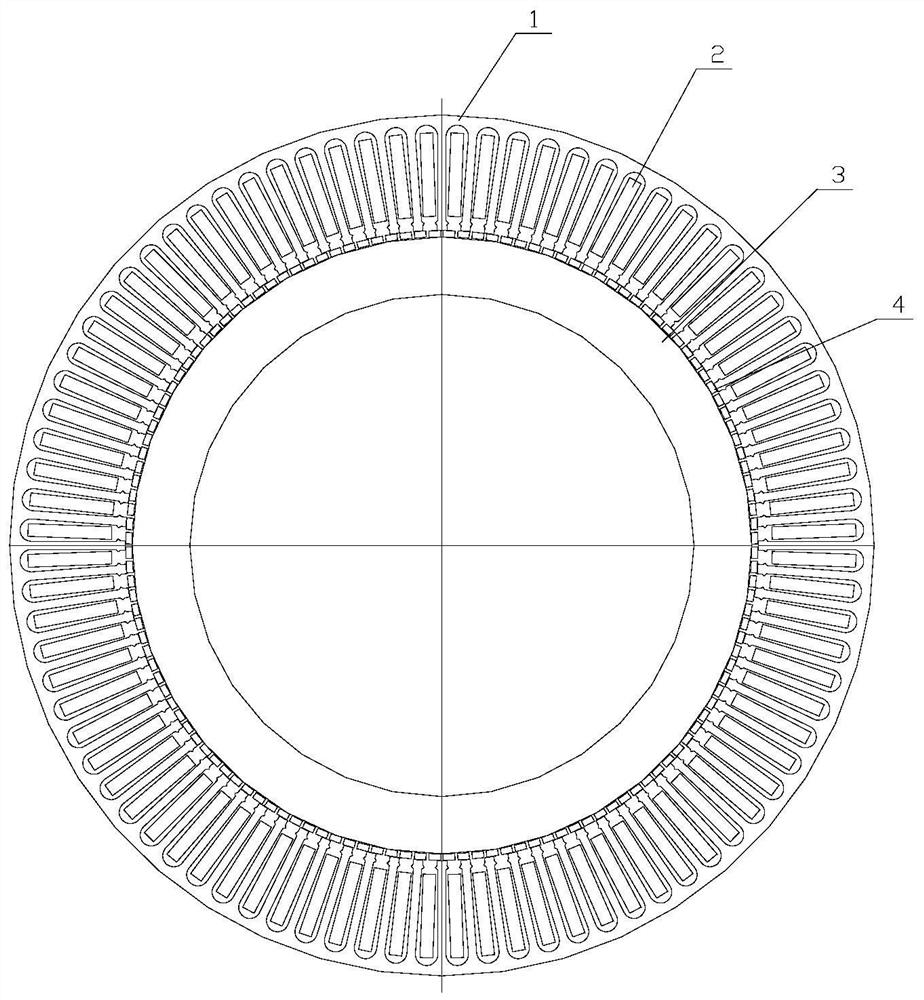

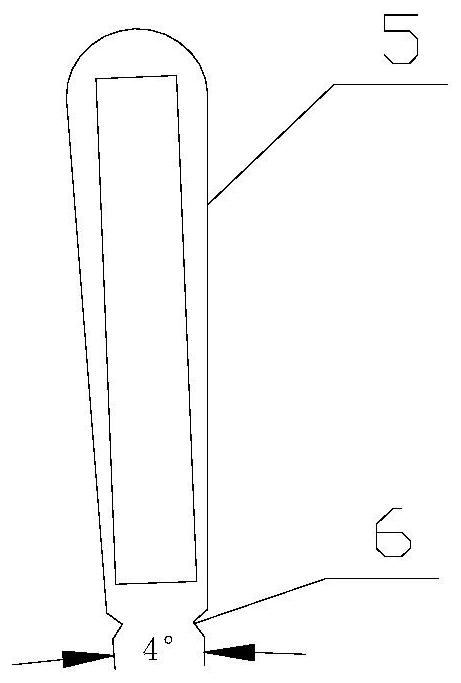

[0018] Such as figure 1 The one shown includes the rotor core 3 and the stator core 1 arranged coaxially. The stator core 1 is formed by stacking several stator punches. The inner ring surface of the stator punches is provided with a winding hole 5, and the stator core is placed in the winding hole 5. The winding 2 and the winding hole 5 are set as long strips distributed radially, and the width gradually increases from the inner ring surface to the outside, and the angle between the edge lines on both sides is 4° (such as figure 2 As shown), the outer ring surface of the rotor core 3 is inlaid with the magnetic steel 4, and the magnetization method of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com