Corrugated film hole with branch holes

A technology of air film holes and corrugated shapes, applied in the direction of blade support components, engine components, machines/engines, etc., can solve the problems that the shape cannot be processed qualifiedly, and there are few complicated special-shaped hole test verifications, etc., to achieve a good air film Coverage area, convenient processing, and the effect of reducing momentum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

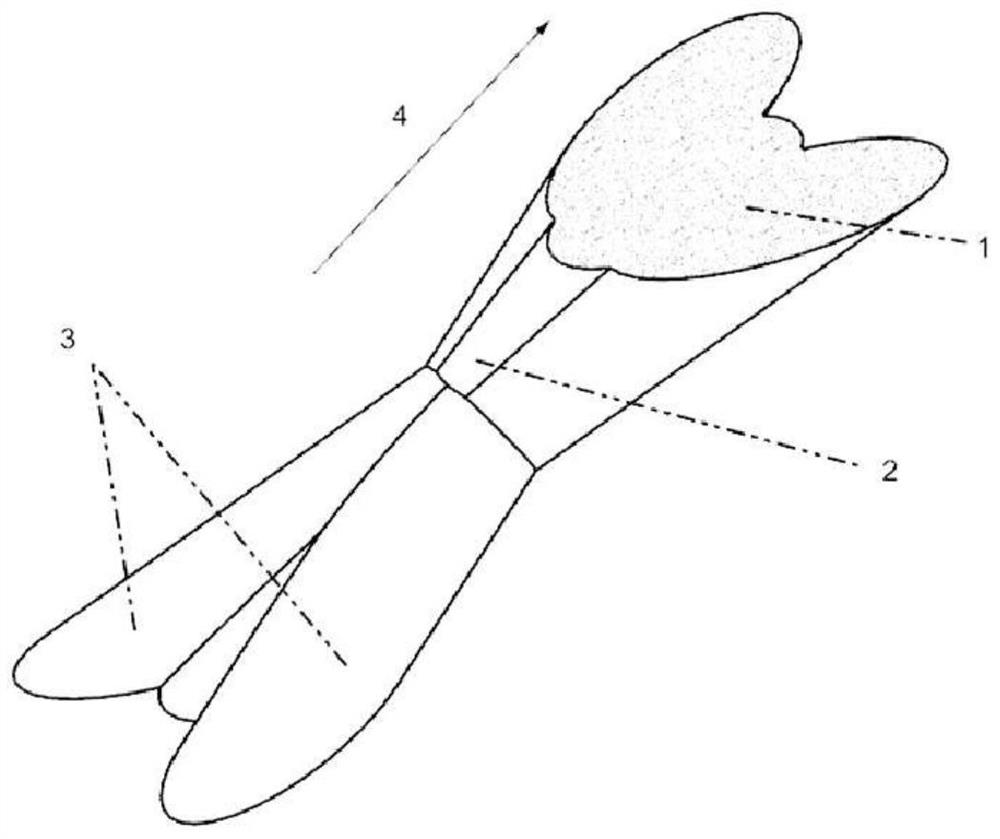

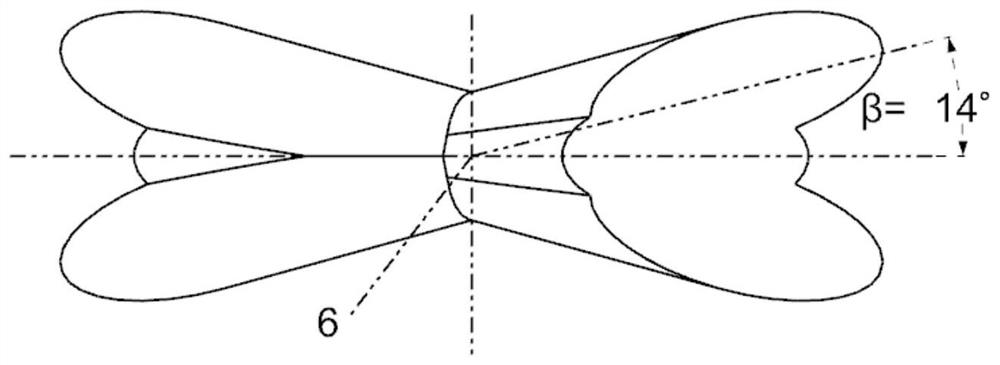

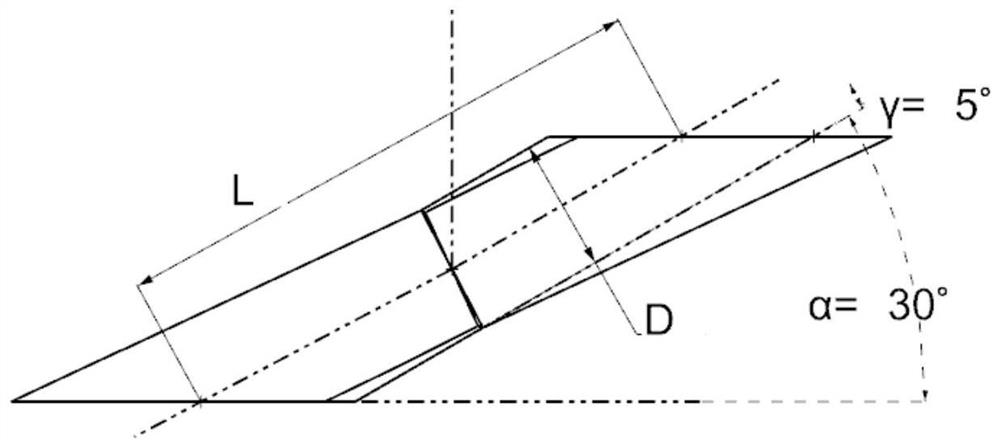

[0029] like figure 1 , as shown in Fig. 2, the corrugated gas film hole with branch hole provided by the present embodiment is double corrugated hole, comprises main hole 2 and two branch holes; The second half section 5 of the two branch holes is arranged on the left and right sides of the front part of the main hole 2, and has a spanwise expansion and backward inclination; the second half section 5 of the two branch holes communicates with the rear part of the main hole 2 , the airflow 4 flows to the outlet section 1 similar to a special-shaped hole along the direction indicated by the arrow.

Embodiment 2

[0031] like image 3 , as shown in Figure 4, the corrugated gas film hole with branch holes provided in this embodiment is a single corrugated hole, including the main hole 2 and the second half section 5 of the two branch holes; the second half section 5 of the two branch holes is connected with the main hole The rear parts of 2 communicate with each other, which is the only difference between the single corrugated hole and the above-mentioned double corrugated hole, mainly due to processing considerations. In the case of limited processing equipment, in order to reduce the damage of the back substrate during laser processing or when the high-temperature component is a multi-layer composite material, the number of processing in a specific area needs to be reduced. Single corrugated holes are used. The inlet cross section 7 of the single corrugated hole is elliptical consistent with the traditional cylindrical hole.

[0032] In the above-mentioned double corrugated hole and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com