Automatic threading equipment for annealing device, and annealing device

An annealing device and automatic wearing technology, applied in the direction of heat treatment equipment, furnace types, furnaces, etc., can solve problems such as burns, whipping burns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiment of automatic threading device:

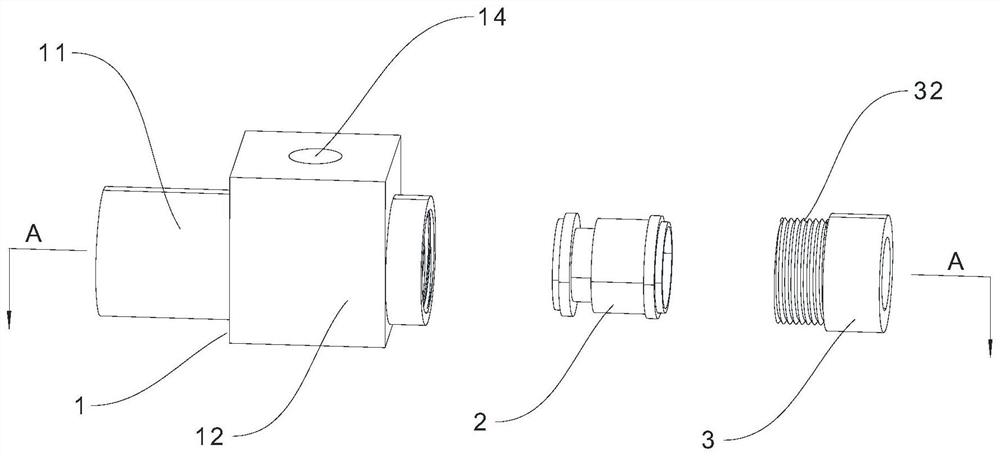

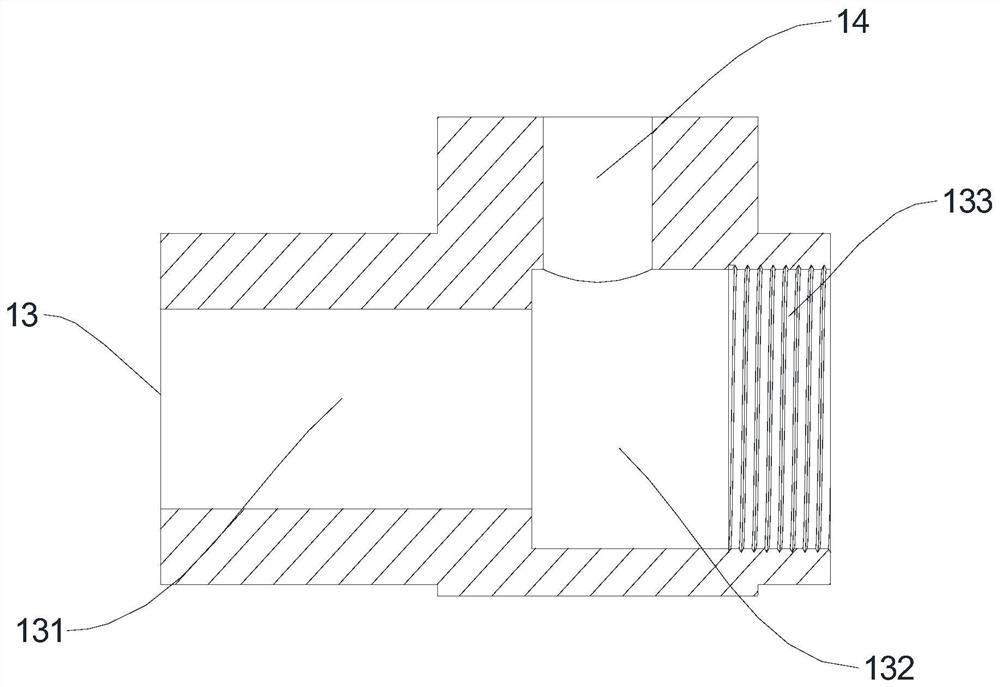

[0028] see Figure 1 to Figure 3 and Figure 5 , The automatic threading device provided in this embodiment includes a shell main body 1 , a functional part 2 and a fastener 3 connected in sequence. The casing main body 1 includes a first main body 11 and a second main body 12 that communicate with each other, and a first through hole 13 is opened along the axial direction of the first main body 11, and an air inlet 14 is opened on the second main body 12. The axes of the through hole 13 and the air inlet hole 14 are perpendicular. The first through hole 13 includes a first communication section 131 and a second communication section 132 , and a first end of the second communication section 132 communicates with the first communication section 131 . The fastener 3 is fixed on the second end of the second communication section 132 , and a third through hole 31 is opened along the axial direction of the fastener 3 , and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com