Chondroitin sulfate sodium salt heat energy circulating device

A technology of sodium chondroitin sulfate and circulation equipment, which is applied in the direction of heat exchangers, indirect heat exchangers, heat exchanger types, etc., which can solve the effect of heat exchange at high temperature loss, poor effect of discharging sludge and sundries, and heat exchange places Easy to dissipate and other problems, to achieve the effect of increasing the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

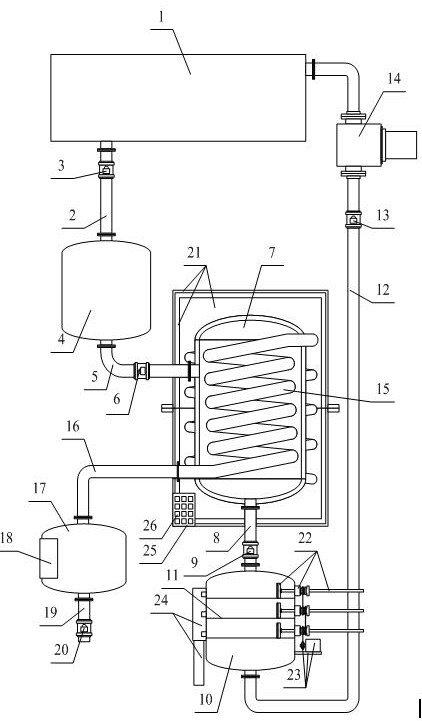

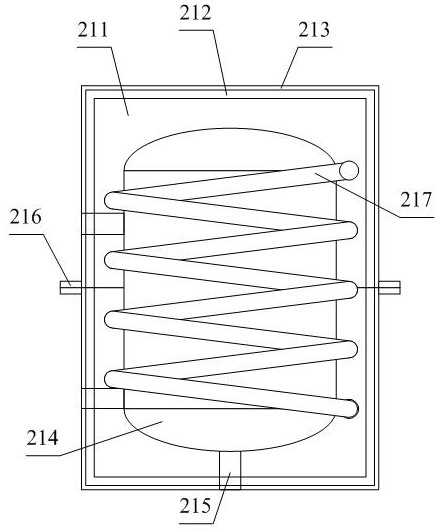

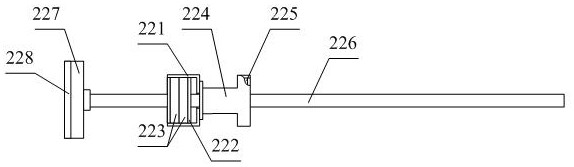

[0039] as attached figure 1 to attach figure 2 As shown, the chondroitin sulfate sodium thermal energy circulation device includes a resin adsorption device 1, a first connecting pipe 2, a first valve 3, a waste liquid tank 4, a second connecting pipe 5, a second valve 6, a storage tank 7, a third Connecting pipe 8, the third valve 9, multi-stage filter 10, filter screen 11, the fourth connecting pipe 12, the fourth valve 13, water pump 14, heat exchange pipe 15, the fifth connecting pipe 16, insulation tank 17, temperature Control heating pipe 18, water outlet pipe 19, fifth valve 20, heat preservation and preheating sleeve structure 21, movable pushing frame structure 22, auxiliary driving wheel structure 23, sealable discharge pipe structure 24, PLC 25 and drive switch 26, One end of the first connecting pipe 2 is connected to the left flange of the lower end of the resin adsorption device 1, and the other end is connected to the upper flange of the waste liquid tank 4; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com