An Improved Splicing Structure of Aluminum Alloy Profiles

A technology of aluminum alloy profiles and connecting blocks, which is applied in the direction of connecting members, thin plate connections, quick-action fasteners, etc., can solve the problems of easy detachment, dislocation, and weak socket structure of the splicing position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The standard parts used in the present invention can be purchased from the market, and the special-shaped parts can be customized according to the instructions and the accompanying drawings. The specific connection methods of each part adopt mature bolts, rivets, welding in the prior art , pasting and other conventional means, no longer described in detail here.

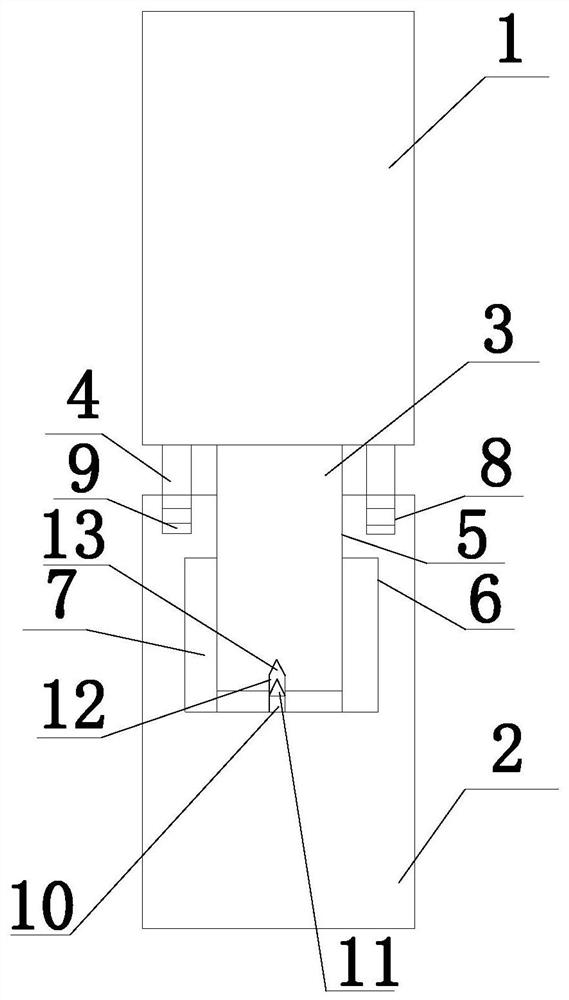

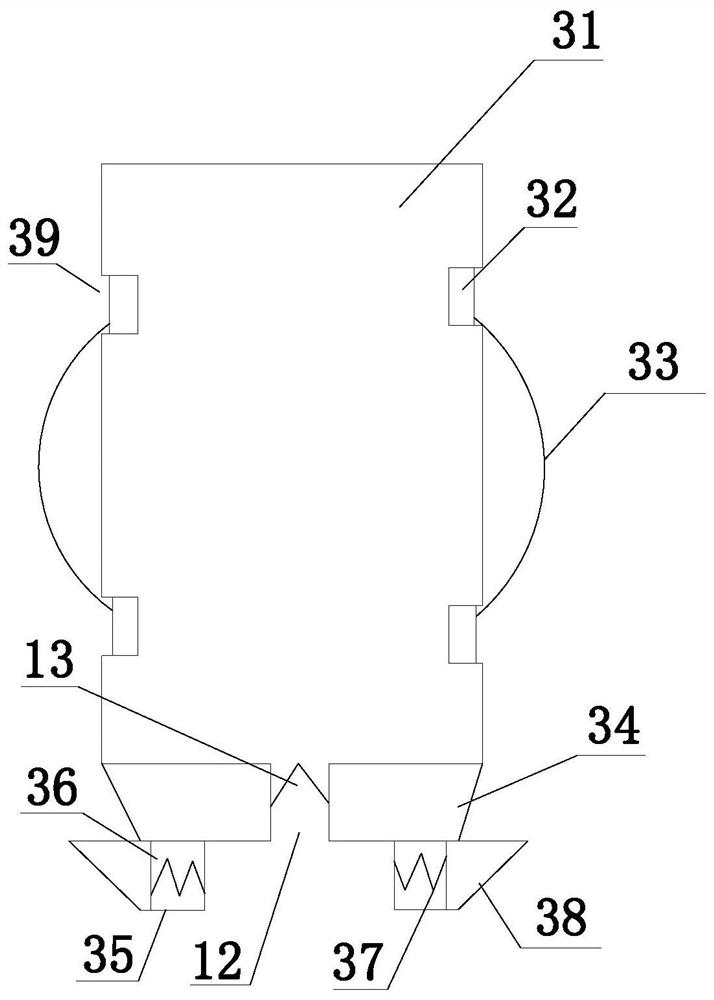

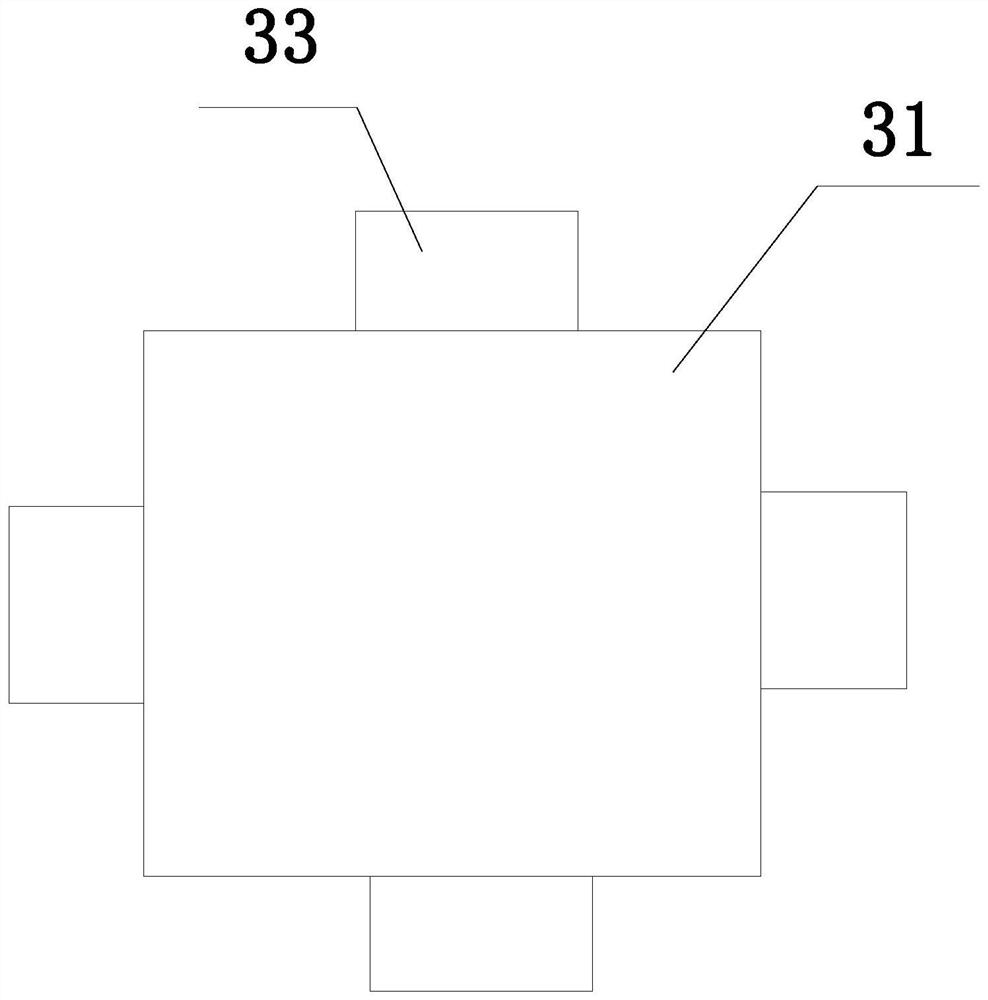

[0018] refer to Figure 1-6, a specific embodiment of the present invention includes a first aluminum alloy profile 1 and a second aluminum alloy profile 2, characterized in that: the center of the bottom surface of the first aluminum alloy profile 1 is fixed with a cuboid connecting block 3, and the bottom surface of the first aluminum alloy profile 1 Two cylindrical blocks 4 are fixed, and the two cylindrical blocks 4 are symmetrically distributed on both sides of the cuboid connecting block 3. The top surface of the second aluminum alloy profile 2 is provided with a first cuboid groove 5, and the cuboid con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com