Flexible inflatable type wind turbine blade and manufacturing method thereof

A wind power generation blade and inflatable technology, which is applied to wind power generation, wind turbines that are consistent with the wind direction, wind turbines, etc., can solve the problems of inconvenient transportation of wind turbine blades, and achieve the effect of reducing transportation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

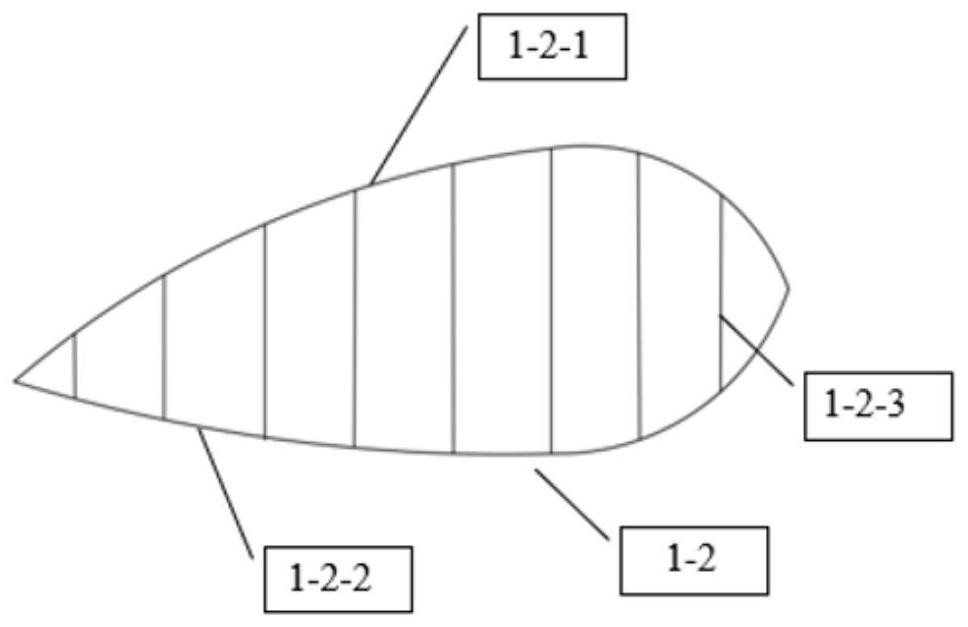

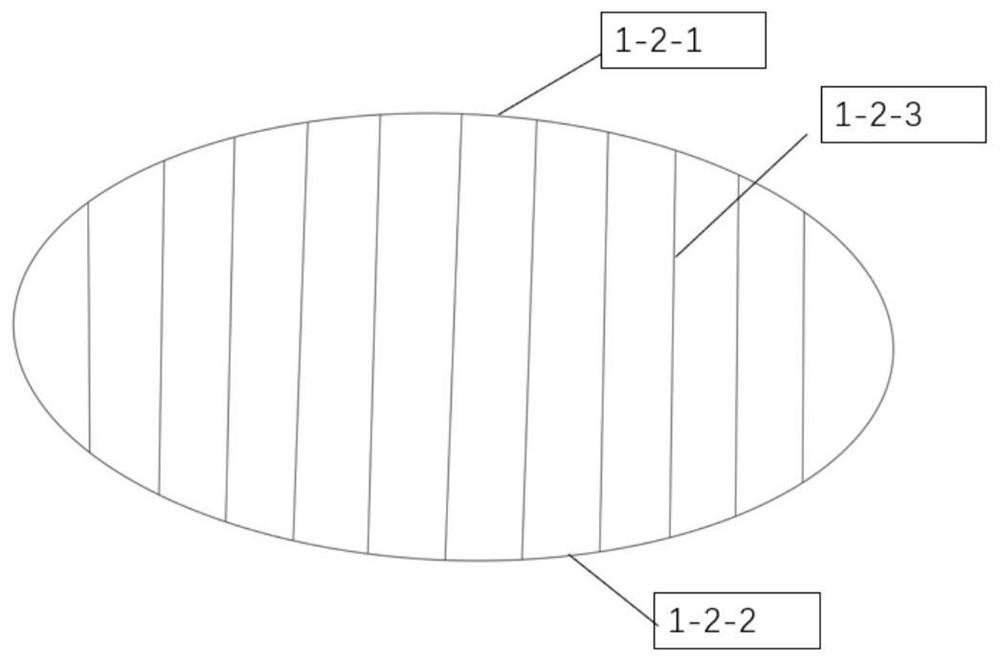

[0030] This embodiment provides a flexible inflatable wind power generation blade. The flexible inflatable wind power generation blade includes an outer layer of a flexible film and an inner layer of a variable-gauge spacer fabric. The shape presented in the straight state is the shape of a wind power generation blade, and the inner layer of the variable-gauge spacer fabric uses high-strength and easy-to-bend high-performance fibers as spacer filaments during preparation, so that the prepared wind power generation blade is naturally In the state, the upper and lower fabrics can be in a bonded state; the outer layer of the flexible film is formed by coating the outer surface of the variable-gauge spacer fabric with a resin that has both sealing and adhesive properties, and an inflatable opening is reserved during coating.

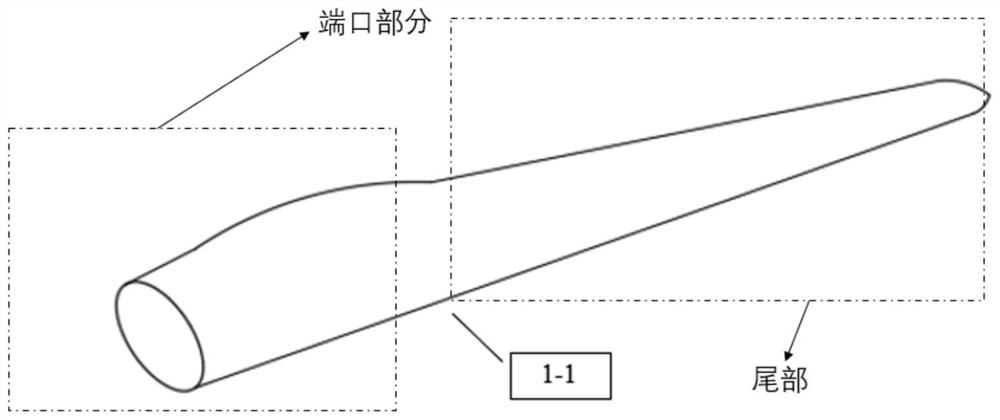

[0031] Such as Figure 1 to Figure 4 As shown, the flexible inflatable wind power blade includes an inner layer and an outer layer. The inner layer is a variab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com