A Larsen steel sheet pile cofferdam and its construction method

A Larsen steel sheet pile and construction method technology, which is applied to sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of inaccurate soil pit size, inability to put steel sheet piles in, and low construction accuracy, so as to increase the use of range, increase installation efficiency and installation accuracy, and reduce the possible effects of irrigation channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following is attached Figure 1-8 The application is described in further detail.

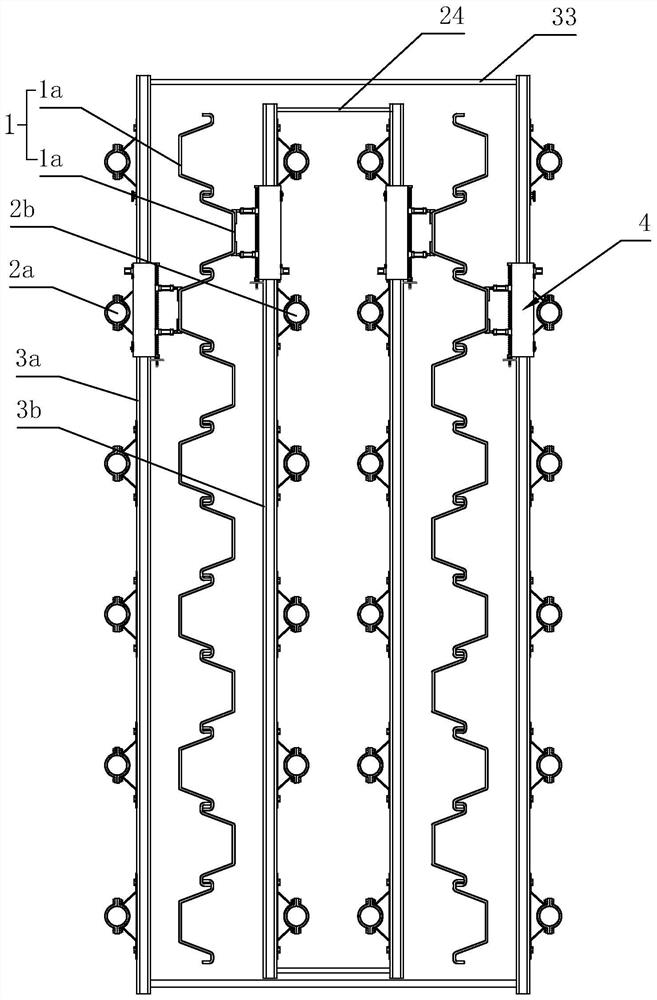

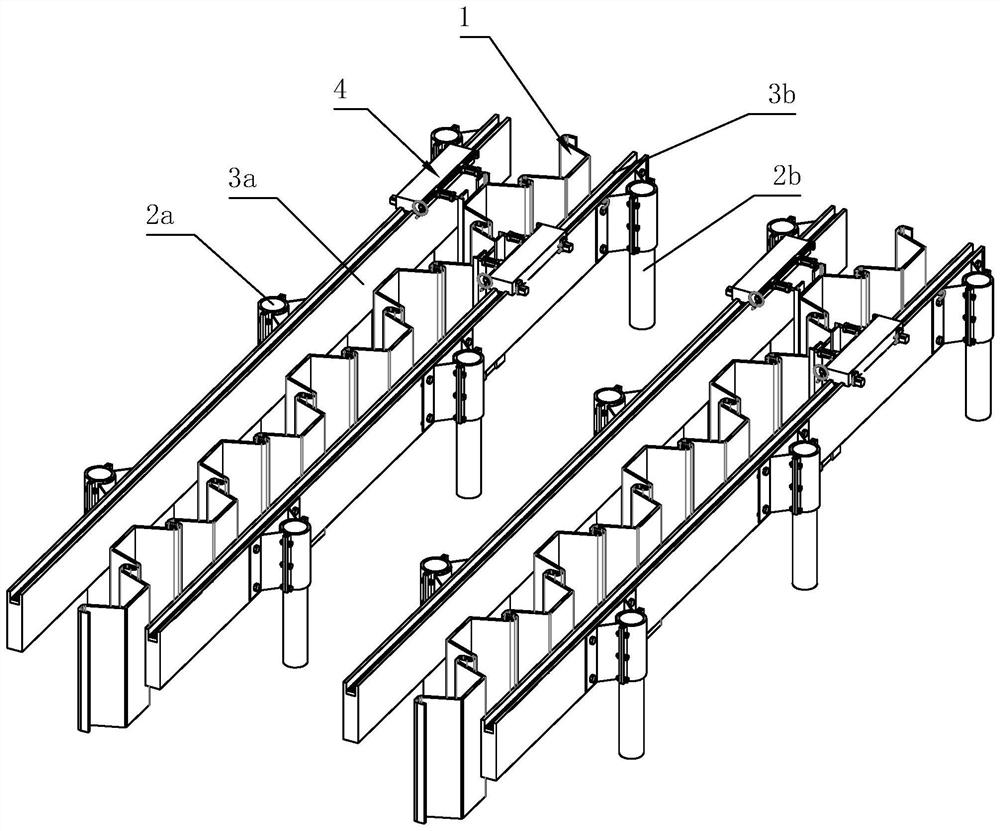

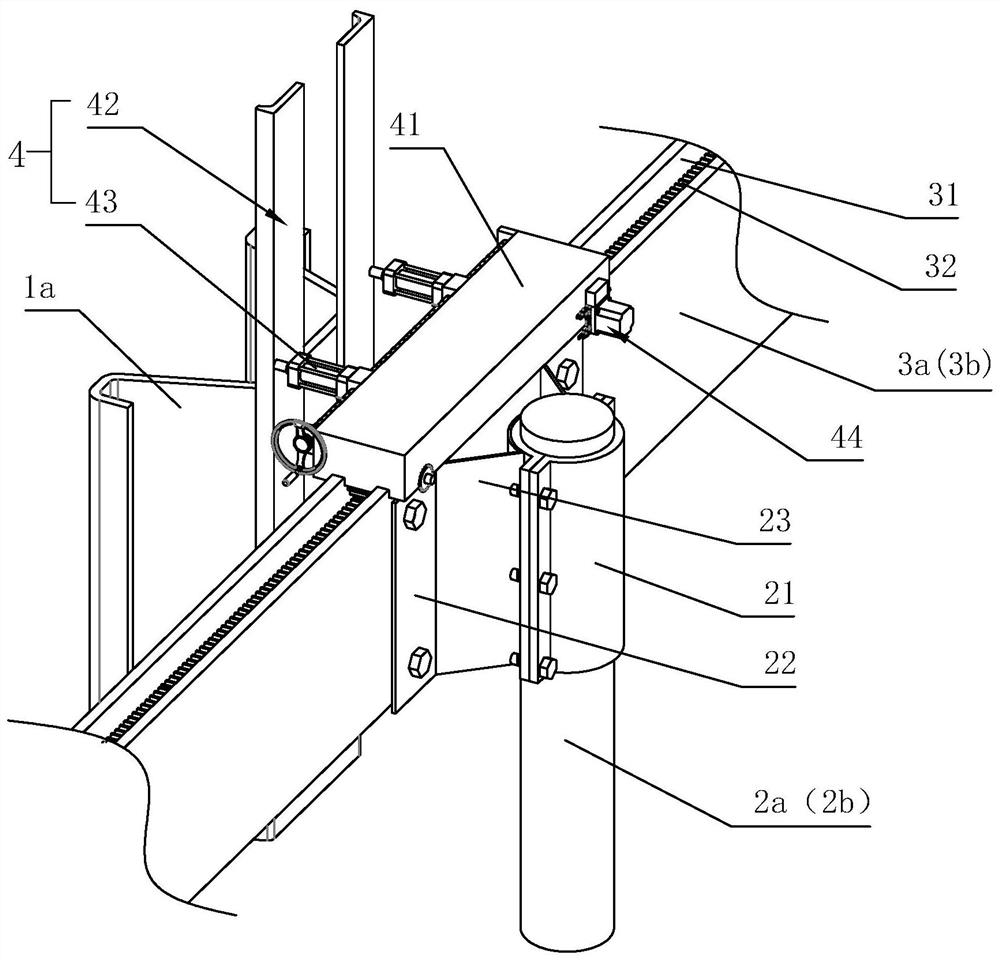

[0048] This application discloses a Larsen steel sheet pile cofferdam, referring to figure 1 , figure 2 , including two rows of Larsen steel sheet piles 1 arranged along the width direction of the river and spliced by multiple Larsen steel sheet piles 1a, two rows of outer foundations parallel to the Larsen steel sheet piles 1 and located on the outside of the two rows of Larsen steel sheet piles 1 Pile 2a, two rows of inner foundation piles 2b which are parallel to Larsen steel sheet piles 1 and located inside the two rows of Larsen steel sheet piles 1 respectively, arranged along the width direction of the river and located between Larsen steel sheet piles 1 and outer foundation piles 2a The outer rail frame 3a and the inner rail frame 3b arranged along the width direction of the channel and located between the Larsen steel sheet pile 1 and the inner foundation pile 2b, the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com