Gas distribution device of optical thin film plasma enhanced atomic layer deposition equipment

An atomic layer deposition, plasma technology, applied in coating, gaseous chemical plating, metal material coating process, etc., can solve the problem of only gas distribution system, improve, can not meet the production needs of optical film, etc., to achieve rapid adjustment , Simple and reasonable structure, easy installation and post-maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

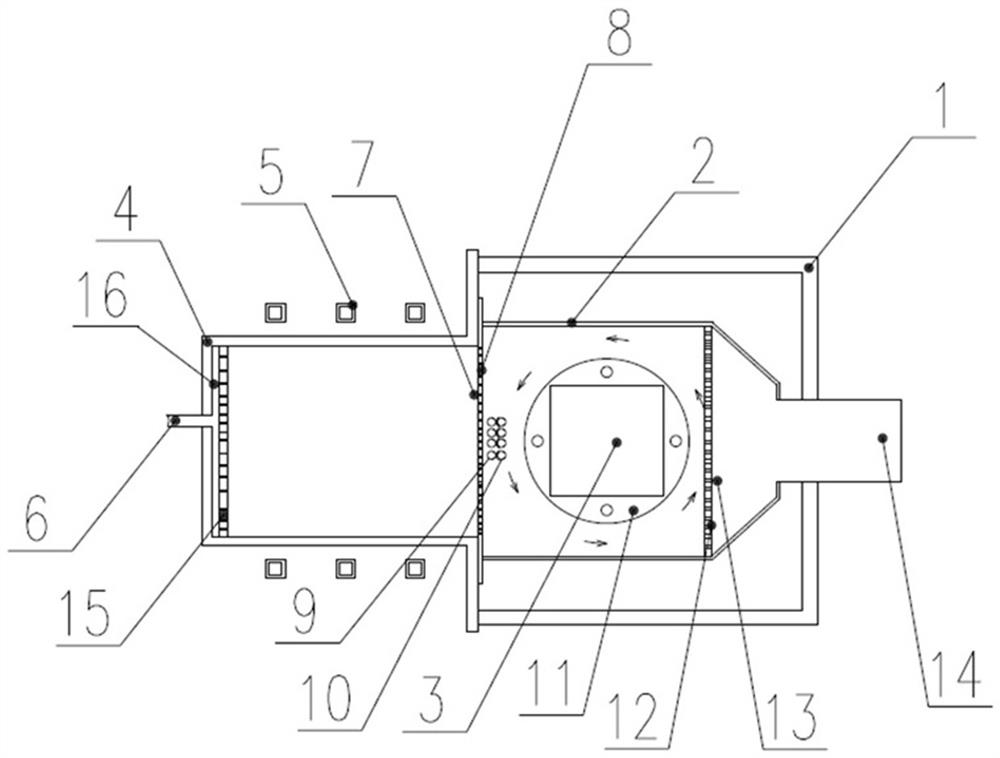

[0026] Embodiment: The gas distribution device of the plasma-enhanced atomic layer deposition equipment for the optical thin film in this embodiment is set on the plasma-enhanced atomic layer deposition equipment, which can be used for the deposition of single-layer or multi-layer optical thin films of different materials.

[0027] like figure 1 As shown, the main body of the plasma-enhanced atomic layer deposition equipment in this embodiment includes an external vacuum chamber 1 , a process chamber 2 , and a plasma component quartz chamber 4 as a plasma chamber.

[0028] Wherein, one end of the plasma component quartz cavity 4 is provided with a plasma component gas inlet 6, and the plasma-related source gas in the plasma-enhanced atomic layer deposition film forming process enters the plasma component quartz through the plasma component gas inlet 6. Inside of cavity 4. Around the plasma assembly quartz cavity 4, plasma assembly steel pipe coils 5 arranged in an array are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com