Turnover box for tobacco transportation

A turnover box and tobacco technology, applied in the direction of transportation and packaging, anti-rot containers, bottle/can parts, etc., can solve the problem of theft of the turnover box, the loss of the package in the middle, the tobacco is easy to be affected by moisture and mildew, and the box body Deformation and other problems, to improve turnover efficiency and storage efficiency, improve warehouse space utilization, and avoid loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

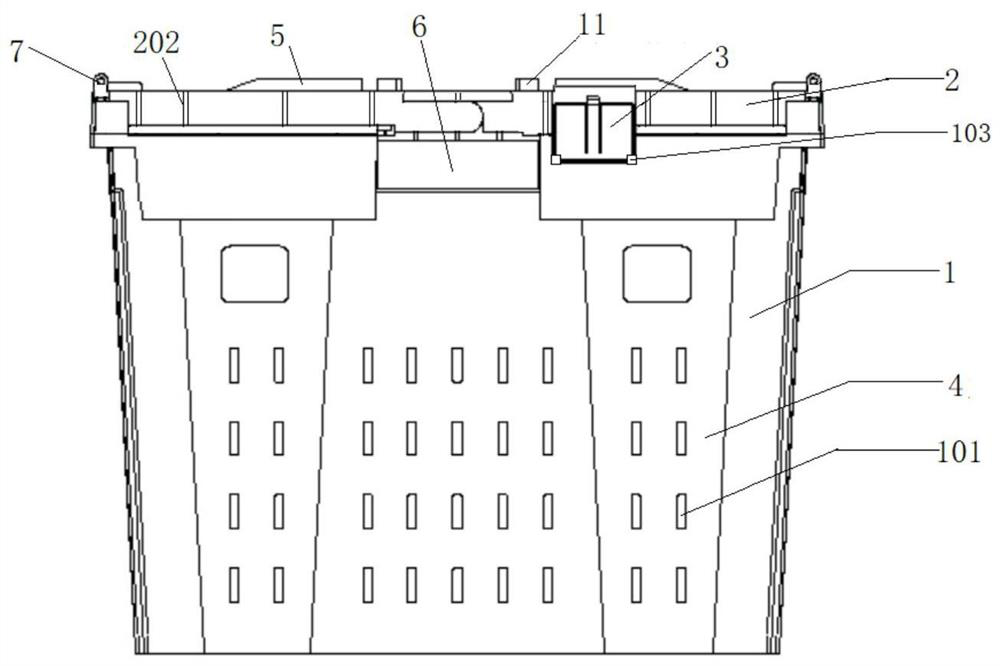

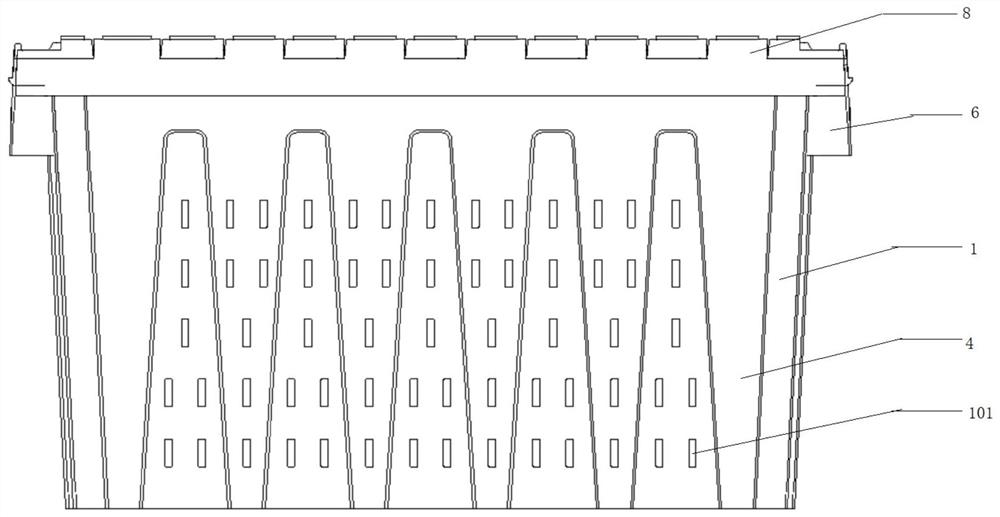

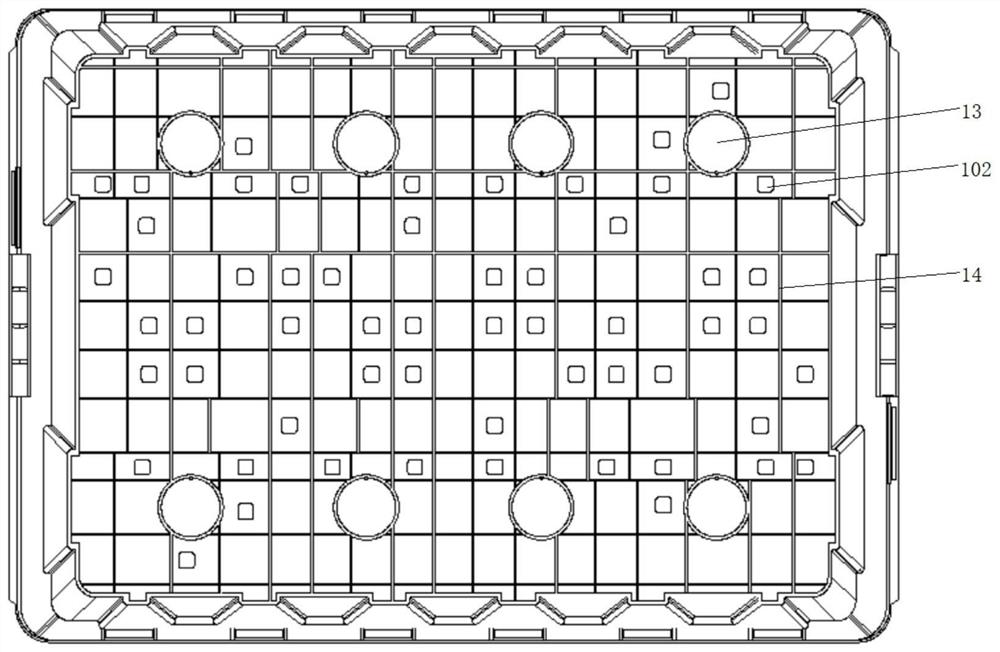

[0135] Embodiment 1 provides a kind of turnover box for tobacco transportation, such as figure 1 As shown, a box body 1 is included; the box body 1 is provided with a cover body 2 . The components on each long side of the box body 1 are symmetrically designed, and the components on the short side are symmetrically designed. The box body 1 includes a turnover box body, a strengthening device, and a box drainage device; the turnover box body is provided with a strengthening device and a box drainage device.

[0136] Such as figure 1 As shown, the reinforcement device includes side reinforcement ribs 4 and bottom reinforcement ribs 14 . The side of the box 1 is provided with 16 side ribs 4; each long side of the box 1 is provided with 6 side ribs 4, and each short side is provided with 2 side ribs 4; The side rib 4 is a trapezoidal rib shape with a wide top and a narrow bottom; the side rib 4 is 8mm higher than the plane where the turnover box body on the same side is; the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com