Upper mold device for lens frame bending forming machine

A molding machine and technology for mirror frames, applied in the field of mirror frame processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

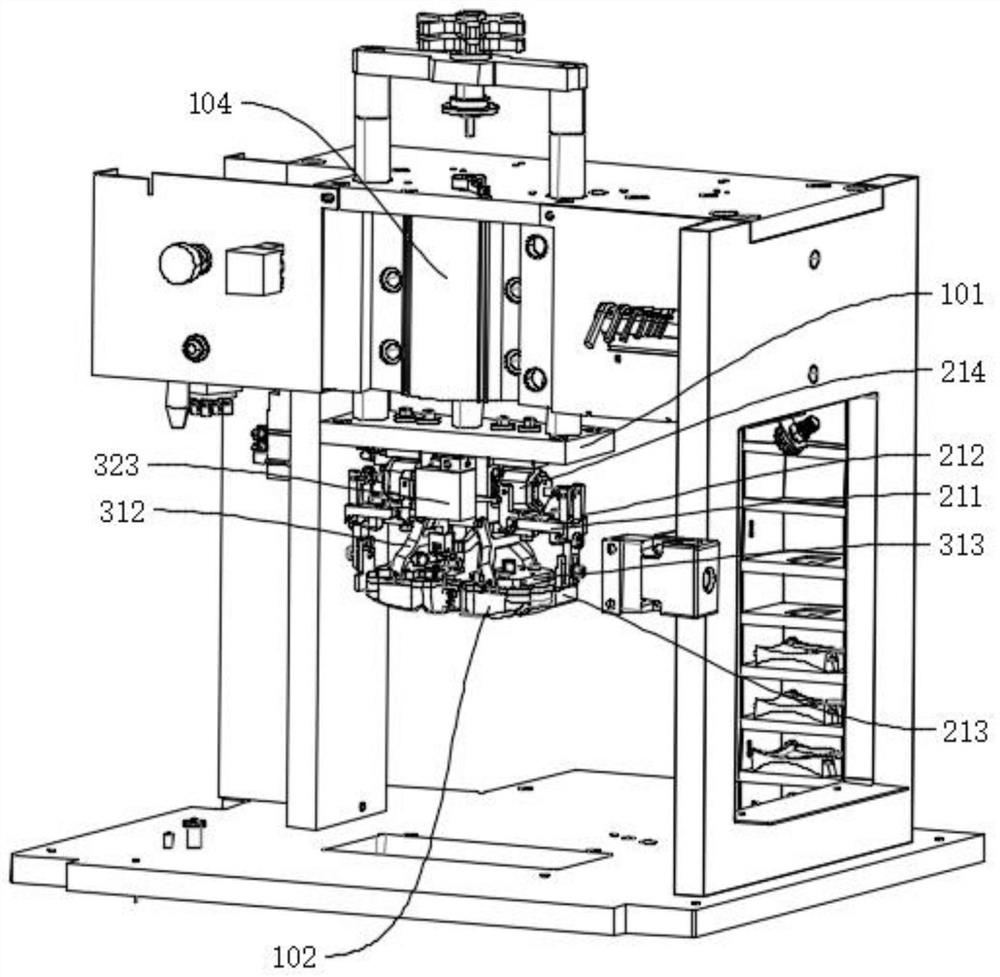

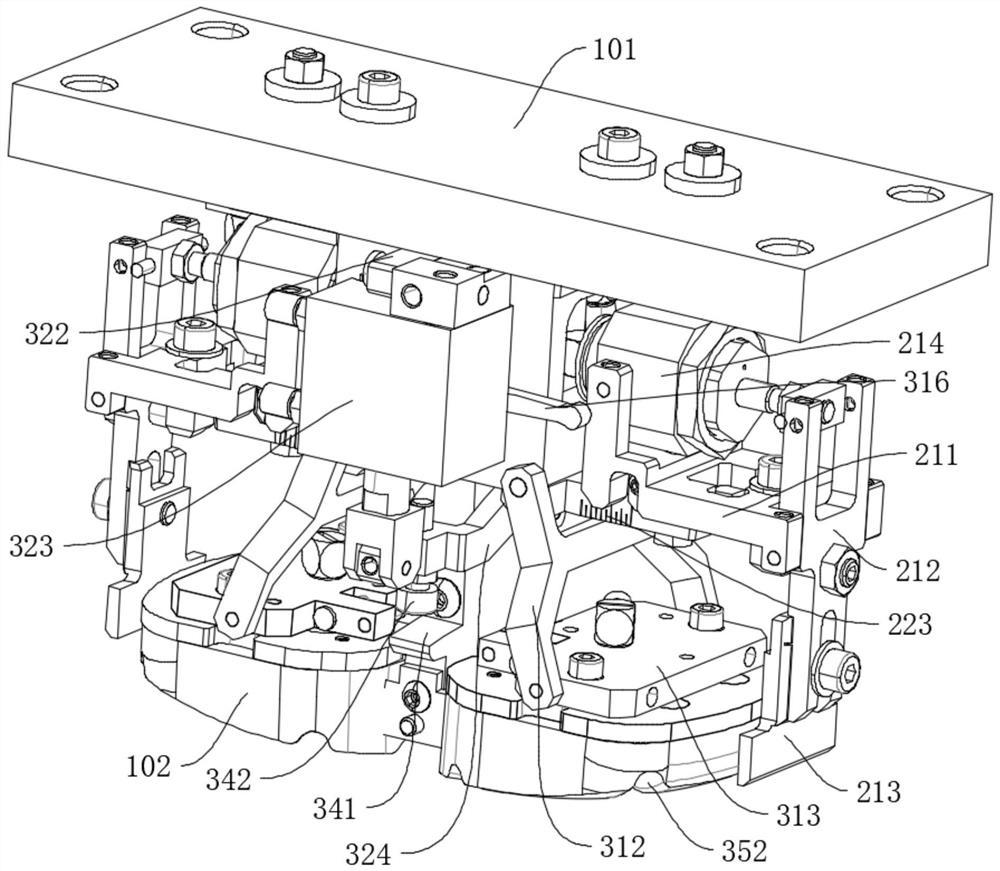

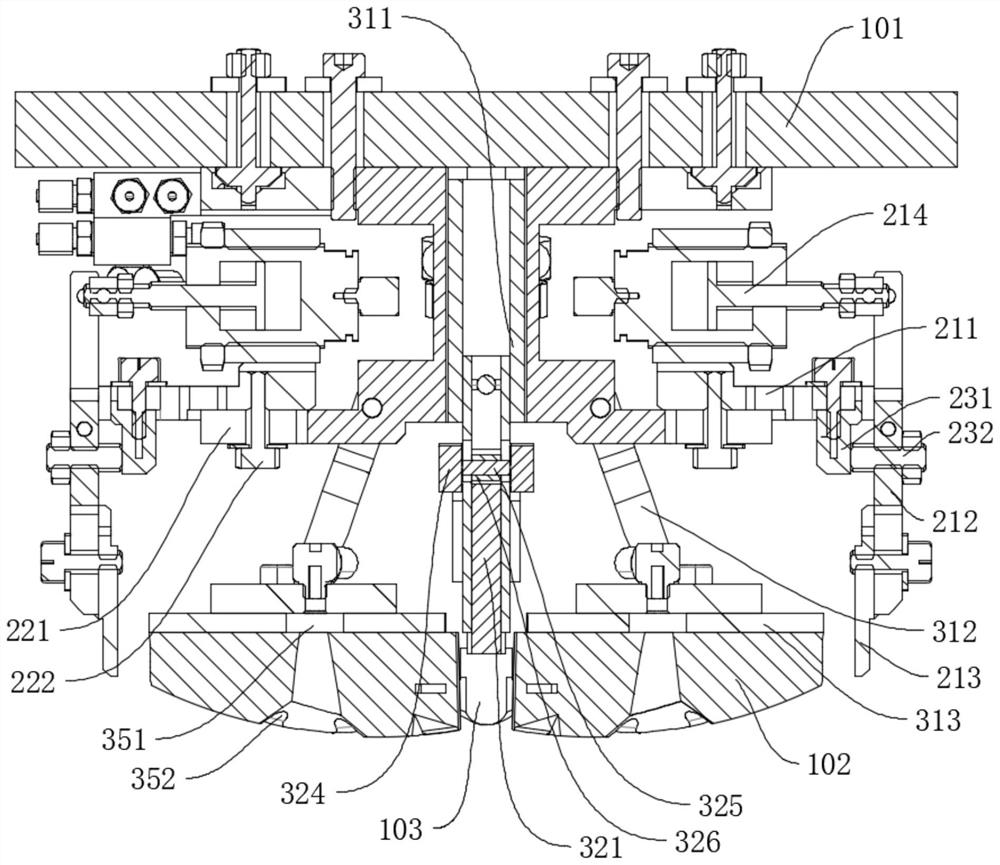

[0034] Such as Figure 1 to Figure 8As shown, the present invention proposes an upper mold device for a mirror frame bending machine, comprising an upper mold base 101 connected to the mirror frame forming machine and capable of moving up and down relative to the mirror frame forming machine, connected between the mirror frame forming machine and the upper mold base 101, and The lifting cylinder 104 that drives the upper mold base 101 to move up and down, and two upper modules 102 that are connected to the upper mold base 101 and abut against the lens frame respectively. The upper modules 102 are made of flexible materials, such as silica gel and rubber. An installation adjustment assembly is arranged between the upper module 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com