A large arc-shaped forging billet forming forging method

A forging billet and arc-shaped technology, which is applied in the field of forming forging with precise control of the bending radian of large-scale arc-shaped forging billets, can solve the problems of forging structure and performance degradation, heating, and long heating time of large forgings, so as to improve the stability of structure performance and reduce The effect of forging fire times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Forging material: TC18, phase transition point 875°C, quantity: 2 pieces, forging blank thickness: 300mm, bending arc angle: R2699, blanking weight, 1850Kg.

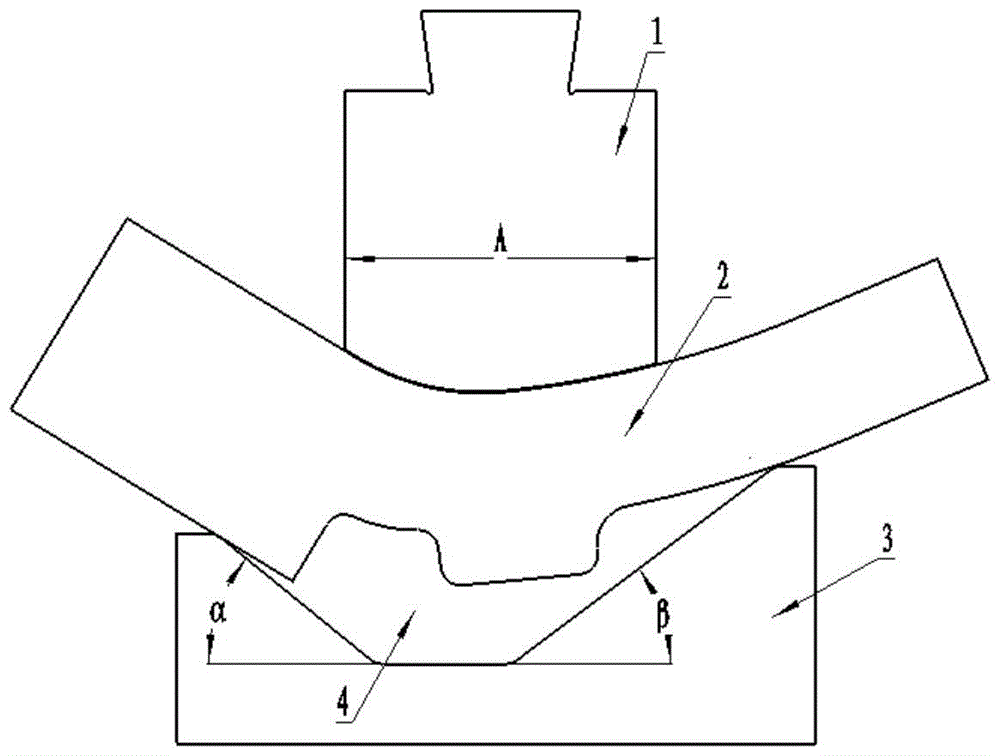

[0023] Step 1: Membrane production

[0024] The lower surface of the upper membrane 1 is an arc-shaped boss with a width A of 300mm, an arc of R2699mm, and a length of 300mm; a dovetail keyway is made on the upper surface of the upper membrane 1 with a height of 350mm. The cavity of the lower membrane 3 is a trapezoidal groove 4 with the same cross section, and the width of the lower membrane 3 is 450°; is α, the acute angle formed by its long side and the plane where the bottom surface of the trapezoidal groove 4 is located is β, and the angles of α and β are respectively 39° and 37°; the height of the short side of the trapezoidal groove 4 is 150mm lower than the long side, and the upper opening The width is 1270mm; the width of the bottom surface of the trapezoidal groove 4 is 340mm, and the maximum...

Embodiment 2

[0039] Forging material: TC8, phase transition point 878°C, quantity: 3 pieces, forging billet thickness: 280mm, bending arc angle: R2585, blanking weight, 1550Kg.

[0040] Step 1: Membrane production

[0041] The lower surface of the upper membrane 1 is an arc-shaped boss, the width A of the boss is 280mm, the radian is R2585mm, and the length is 300mm; a dovetail keyway is made on the upper surface of the upper membrane 1, and the height dimension is 350mm. The cavity of the lower membrane 3 is a trapezoidal groove 4 with the same cross section, and the width of the lower membrane 3 is 450°; is α, the acute angle formed by its long side and the plane where the bottom surface of the trapezoidal groove 4 is located is β, and the angles of α and β are respectively 37° and 35°; The width is 1270mm; the width of the bottom surface of the trapezoidal groove 4 is 300mm, and the maximum height of the lower membrane 3 is 650mm.

[0042] Step 2: Forging a suitable elongated forging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com