Supporting device for turning long-axis workpiece

A supporting device and workpiece car technology, applied in the field of CNC lathes, can solve problems such as laborious handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

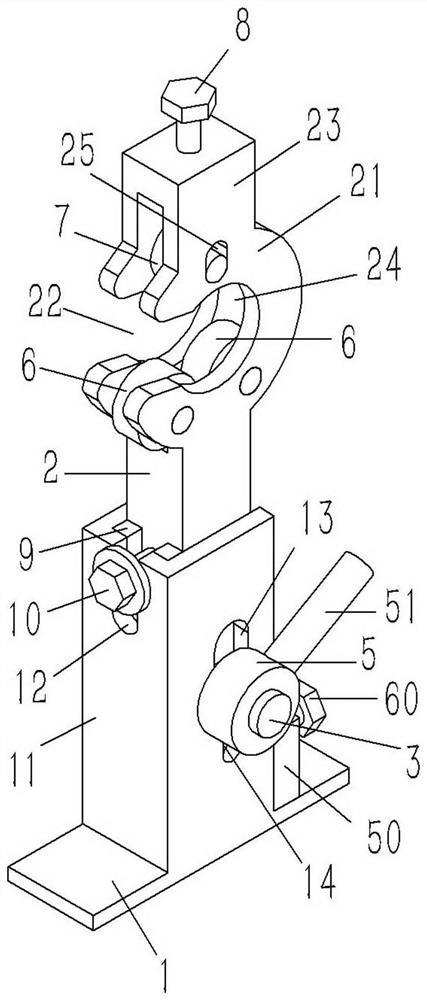

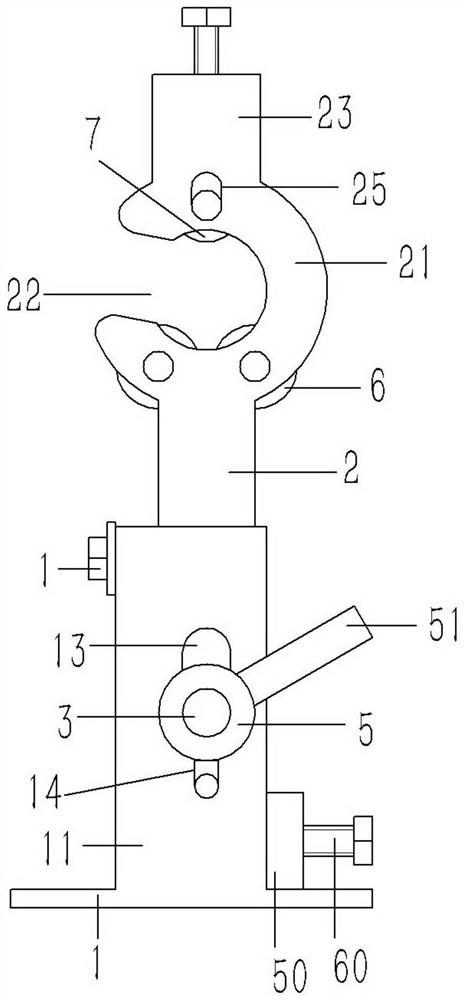

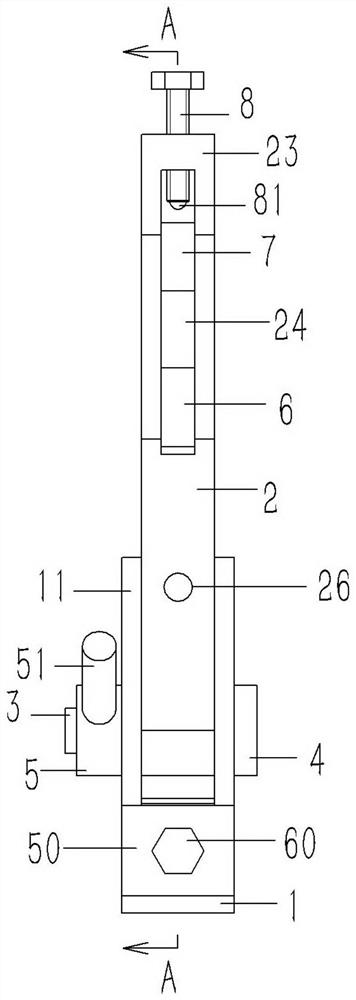

[0020] Example: see Figures 1 to 4 As shown in the figure, a support device for long-axis workpiece turning includes a base 1 on which a support seat 11 with a cross-section in the shape of a "匚" is formed, and a support rod 2 is inserted into the support seat 11. The lower end is plugged and fixed with a hinge shaft 3, and the two ends of the hinge shaft 3 pass through the support base 11 to insert and fix the limit sleeve 4 and the connection sleeve 5 respectively, and the outer wall of the connection sleeve 5 is formed with an insertion rod 51; the support rod 2 A threaded hole 26 is formed on the side wall of the upper part, and the limit bolt 10 is screwed in the threaded hole 26. A U-shaped notch 12 is formed on the side wall opposite to the upper end of the support seat 11, and the limit bolt 10 is inserted into the In the U-shaped notch 12 of the support seat 11;

[0021] The upper end of the support rod 2 is formed with a circular support sleeve 21, the top of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com