Loaded activated carbon, preparation method and device thereof

An activated carbon and supported technology, applied in the field of supported activated carbon and its preparation, can solve the problems of long production cycle, large material loss, complicated operation, etc., and achieve the effects of increasing the load, high production efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The invention provides a kind of preparation method of supported activated carbon, comprises the following steps:

[0062] Vacuumize the reaction kettle equipped with activated carbon, and then introduce the impregnating liquid into the reaction kettle for impregnation treatment to obtain supported activated carbon.

[0063] The invention carries out vacuum treatment on the reactor equipped with activated carbon. The present invention has no special limitation on the activated carbon, and the activated carbon well known to those skilled in the art can be used; in the present invention, the activated carbon preferably includes DDT-046 formula activated carbon or DDT-030 formula activated carbon, wherein, at a temperature of 25°C , Air pressure 101.325KPa, the index parameters of described DDT-046 formula activated carbon and DDT-030 formula activated carbon are shown in Table 1; The measuring method of each index is specifically as follows:

[0064] pH: After mixing 10g...

Embodiment 1

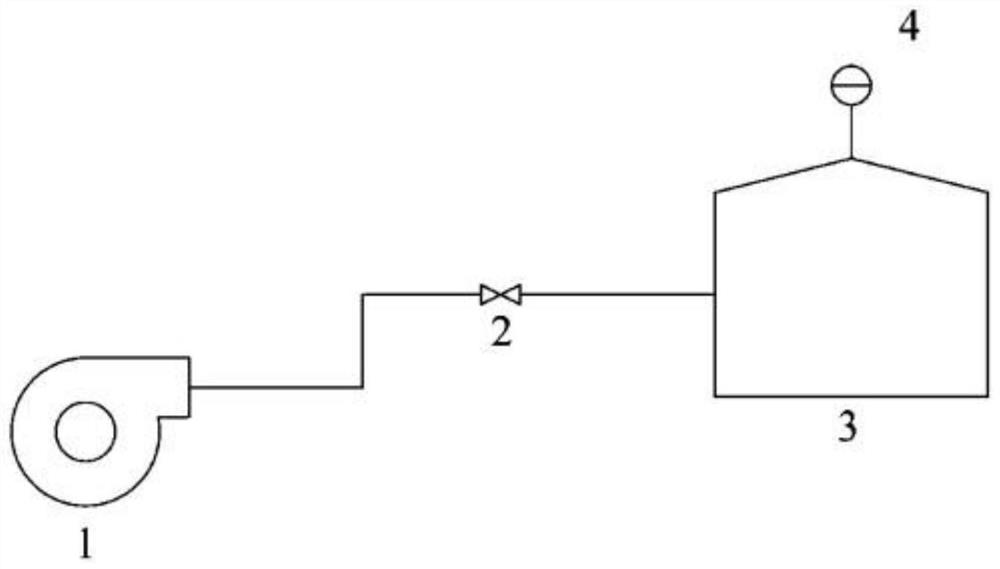

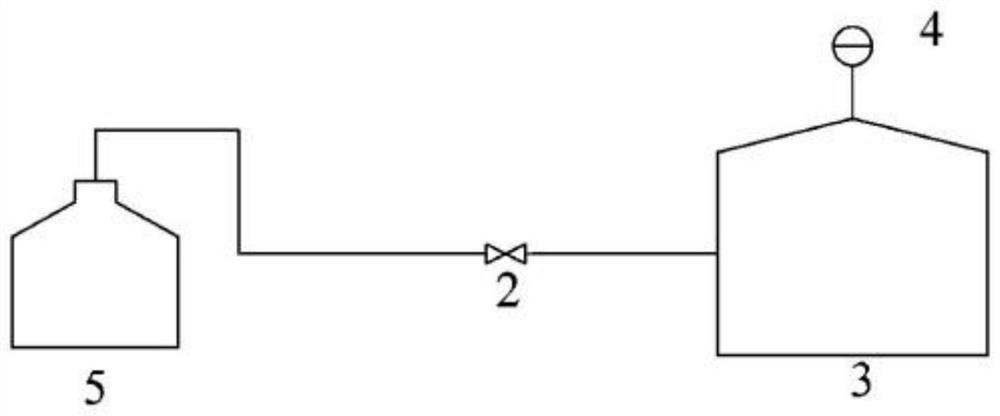

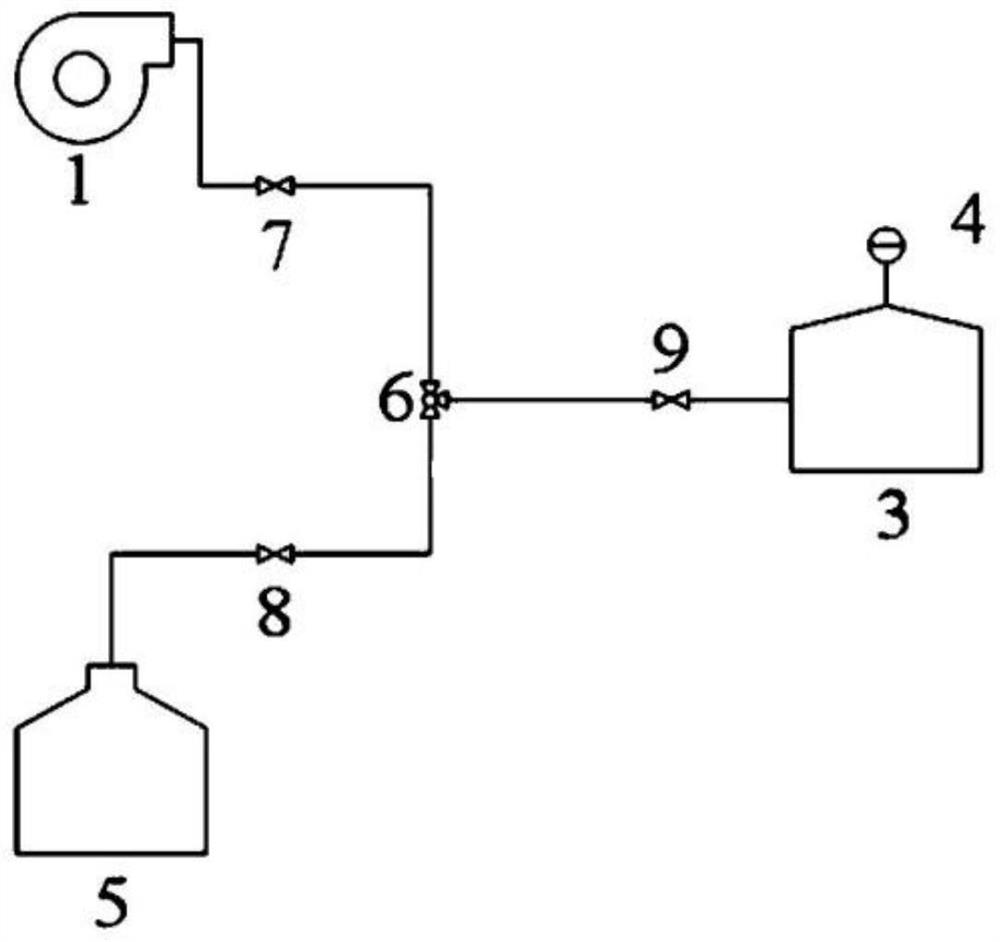

[0082] use figure 1 with 2 The device prepares loaded activated carbon, comprising the following steps:

[0083] Connect the reactor 3 and the vacuum pump 1 through a conduit with a valve 2, put activated carbon (DDT-046 formula activated carbon, see Table 1 for specific index parameters) in the reactor 3, and seal the reactor 3 with a sealing plug; then turn on the vacuum pump 1. Vacuumize the reaction kettle 3 (calculate the vacuum through the pressure indicated by the pressure gauge 4, and the vacuum degree is 0.05MPa), close the valve 2 and then turn off the vacuum pump 1, and maintain the vacuum in the reaction kettle 3 for 30 minutes; Ethylenetriamine aqueous solution, the mass fraction of diethylenetriamine is 13.3%; the mass ratio of activated carbon to impregnating liquid is 1:3) into the dispensing box 5, remove the vacuum pump 1, connect the reaction kettle 3 to the dispensing box 5, Open the valve 2, and use the pressure difference to introduce the impregnating l...

Embodiment 2

[0085] The supported activated carbon was prepared according to the method of Example 1, the difference being that when the reactor 3 was vacuumed, the degree of vacuum was 0.04MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com