Mass fixable by actinic radiation, and use of said mass

A technology of actinic radiation and radiation curing, used in non-polymer organic compound adhesives, adhesive heating methods for adhesives, coatings, etc. problem, to achieve the effect of good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0150] To produce the curable composition according to the invention, the isocyanate-reactive component is first mixed with the passivating agent. The micronized solid isocyanate is then added and the mixture is thoroughly mixed by means of a vacuum kneader. Then other isocyanate-reactive components, radiation-curing components, photoinitiators and all other additives (E), such as catalysts, stabilizers or thixotropes, are added while excluding light with a wavelength of less than 500 nm. Solid additives can also be introduced into the liquid formulation components as pre-solutions or suspensions.

[0151] The overall composition was thoroughly mixed with a vacuum kneader and filled into opaque cartridges.

[0152] To manufacture the curable composition according to the comparative example, a similar method was used.

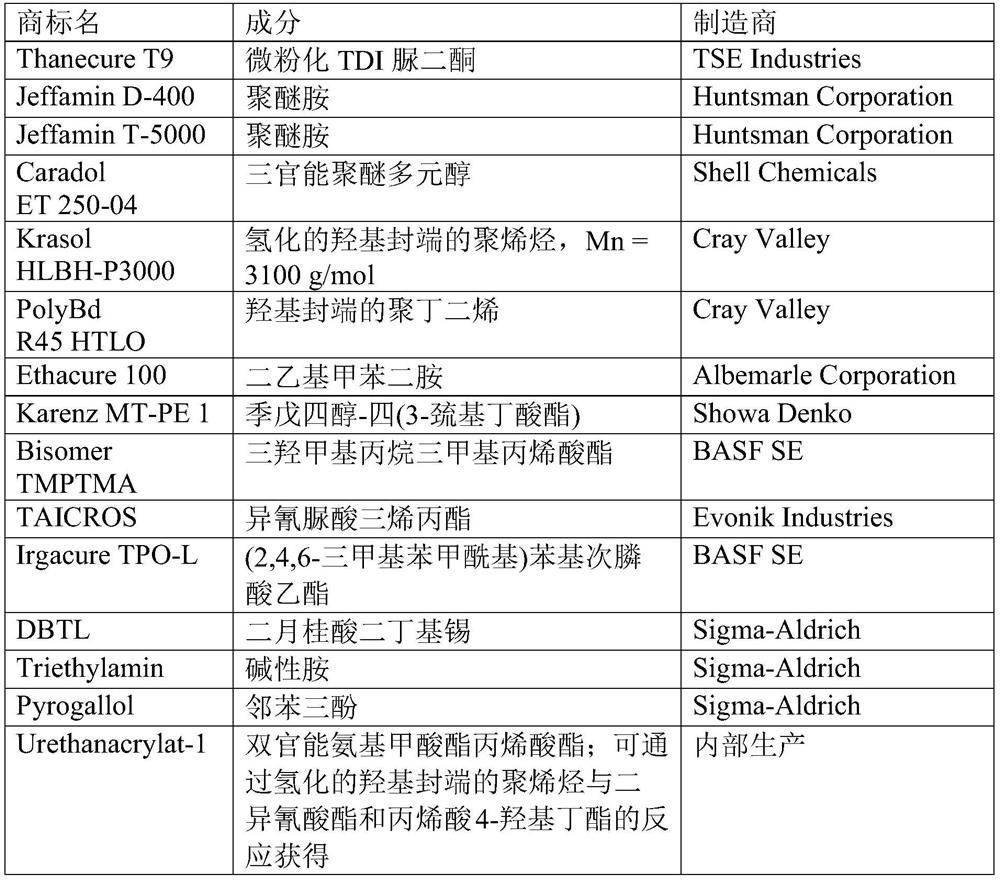

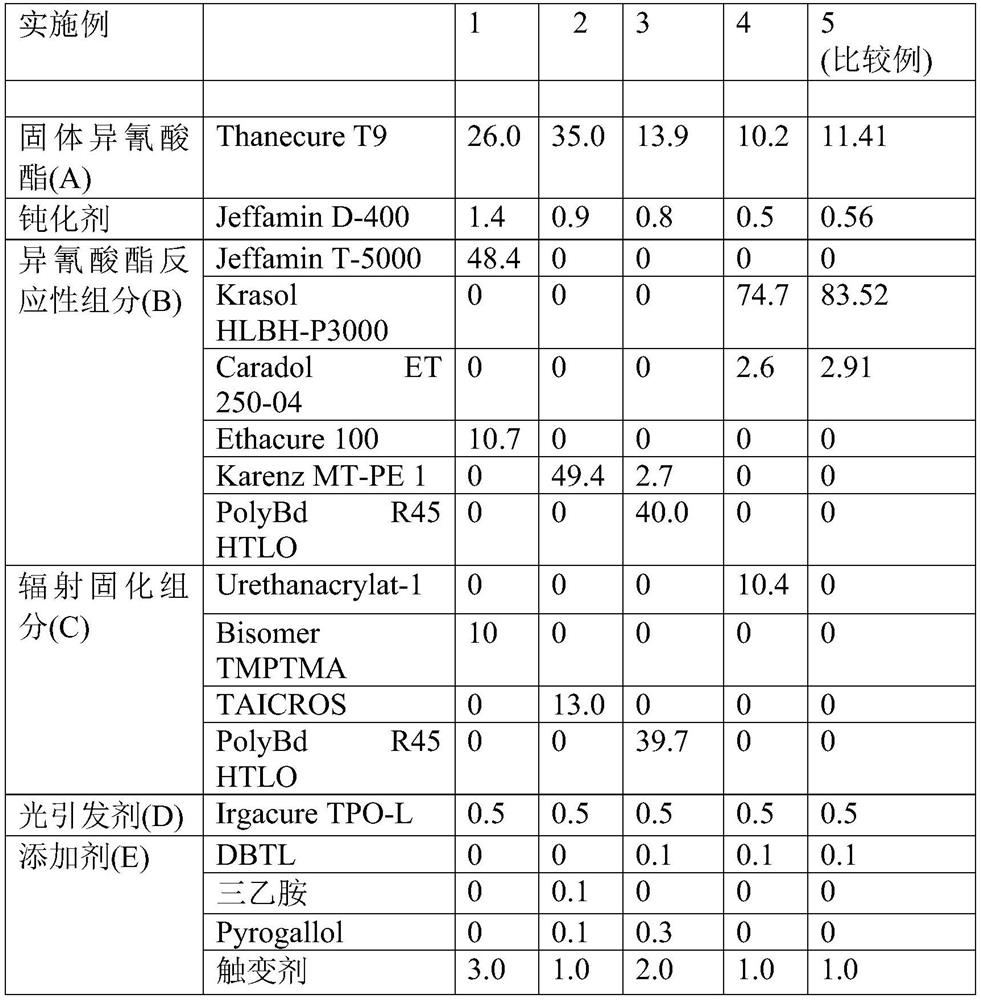

[0153] Table 1 below lists the components used to make the curable compositions:

[0154] Table 1: Components of the curable composition

[0155]

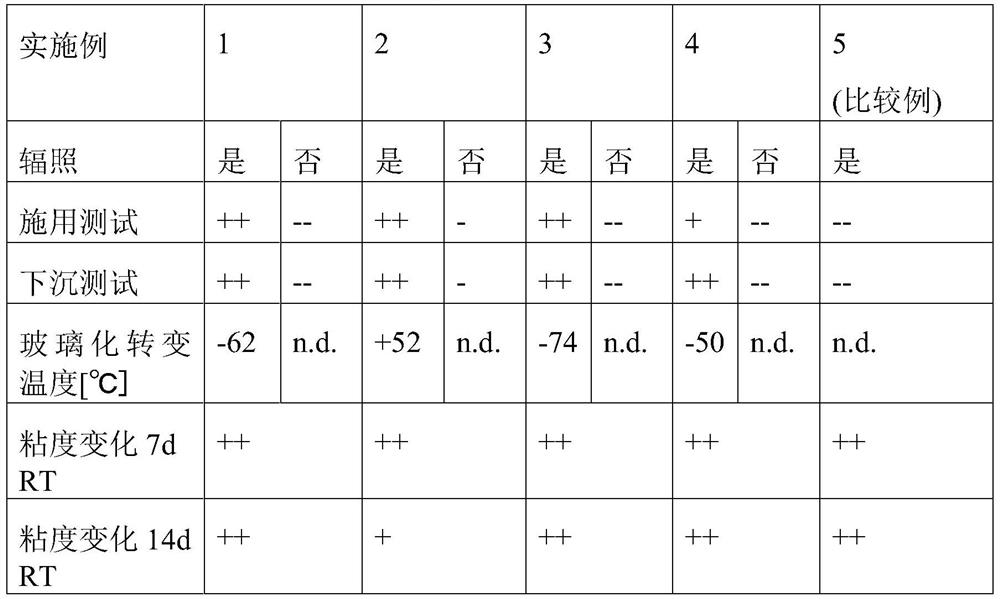

[0156...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com