Thermal inductance feedback device and method for virtual fire-fighting drilling

A feedback device and fire-fighting technology, applied in educational appliances, air heaters, fluid heaters, etc., can solve the problems of inaccurate collection of hot gas, large size of equipment, complex structure, etc., to improve the ability of feedback to users, device Simple and convenient to use and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

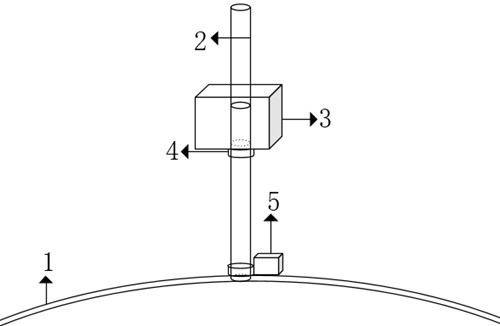

[0020] See figure 1 , a thermal feedback device and method for a virtual fire drill according to the present invention, comprising:

[0021] The fixed rotating shaft device 1 is made of hard plastic material, and is a fixture of the device, which is used to fix the device according to the shape of the semi-ellipse.

[0022] Lifting rod 2 is made of wooden material with gear grooves, is a device for placing hot air blower 3 and power output unit 5, and is automatically connected with fixed rotating shaft 1.

[0023] The hot air blower 3 is a comprehensive control unit composed of multiple control units, which is the heat induction emitter of the whole device. The baffle is used to control the direction of the heat generated.

[0024] The control unit 4 is the data processing and control unit of the entire device. First, extract the corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com