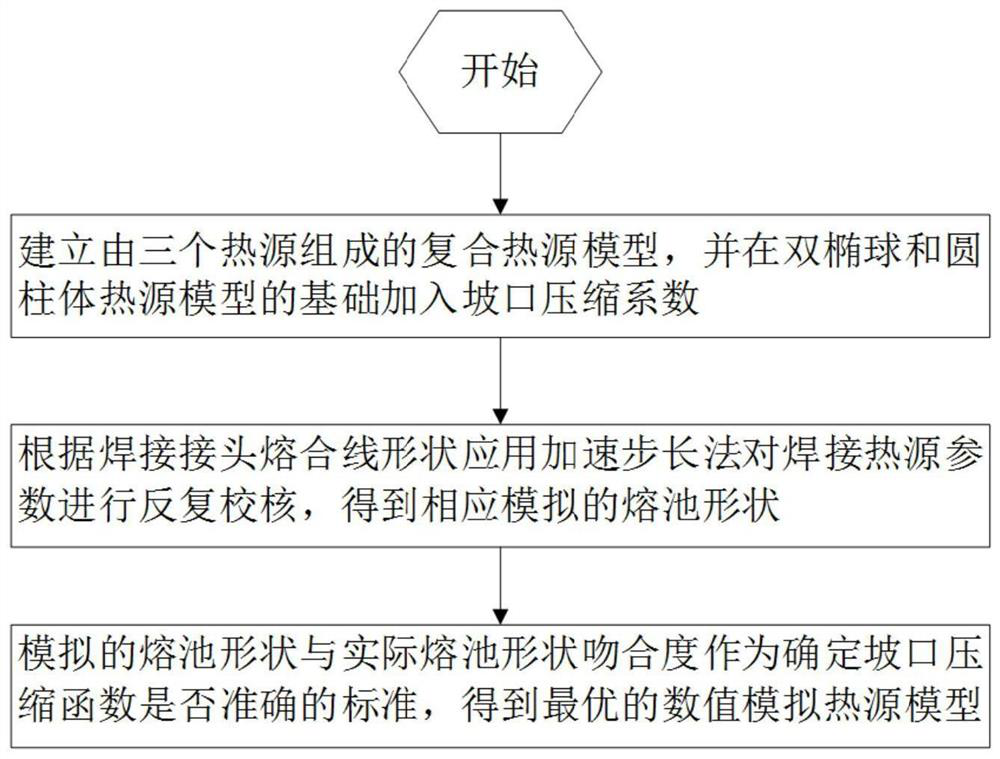

Modeling method of laser arc heat source model based on groove compression coefficient

A laser arc heat source and compressibility technology, applied in CAD numerical modeling, special data processing applications, design optimization/simulation, etc., can solve the problem of low accuracy of heat source model, and achieve the effect of solving the problem of width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

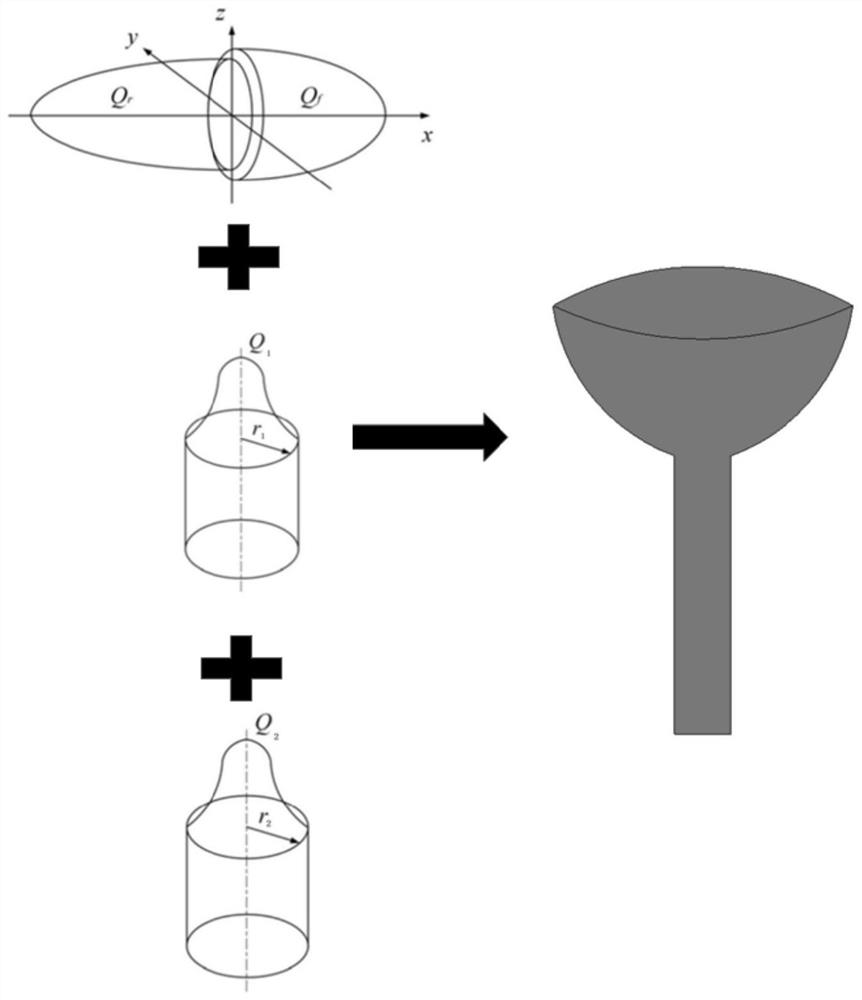

Method used

Image

Examples

specific Embodiment example 1

[0064] Cut the alloy steel plate of 150mm×80mm×18.4mm, make a 30° V-shaped groove, and perform three-pass composite heat source multi-pass welding. The sample size is as follows: figure 2 shown. After cutting and surface treatment of X80 high-strength pipeline steel, debris and oil will exist on its surface. Therefore, before welding, sand the sample with sandpaper, then clean the sample with acetone, and finally wipe it with alcohol. The process parameters shown in Table 1 are used for welding.

[0065] Table 1 The welding process parameters used in Example 1

[0066]

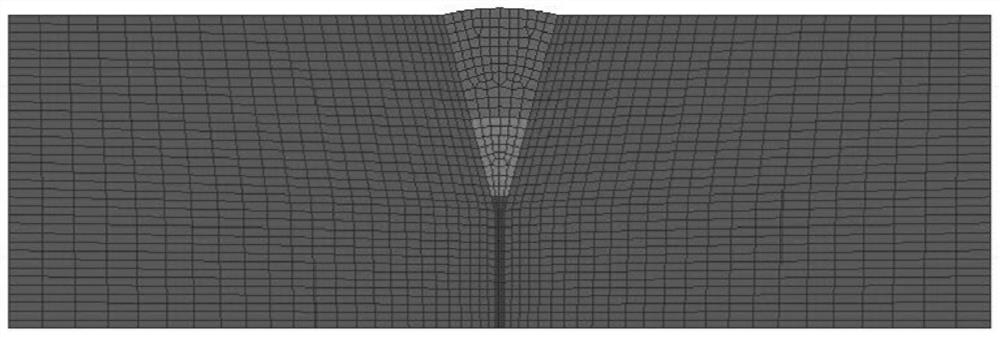

[0067] In order to ensure better calculation accuracy and less calculation amount, different division methods and grid density were carried out in different regions according to the model when dividing the grid. The solid70 hexahedral thermal analysis unit was used in the weld and its surrounding areas and For fine mesh division, the solid70 hexahedral thermal element is used for coarse mesh division in...

specific Embodiment example 2

[0072] Cut the alloy steel plate of 150mm×80mm×18.4mm, make a 30° V-shaped groove, and perform three-pass composite heat source multi-pass welding. The sample size is as follows: figure 2 shown. After cutting and surface treatment of X80 high-strength pipeline steel, debris and oil will exist on its surface. Therefore, before welding, sand the sample with sandpaper, then clean the sample with acetone, and finally wipe it with alcohol. The process parameters shown in Table 2 are used for welding.

[0073] The welding process parameters used in the second example of Table 2

[0074]

[0075] In order to ensure better calculation accuracy and less calculation amount, different division methods and grid density were carried out in different regions according to the model when dividing the grid. The solid70 hexahedral thermal analysis unit was used in the weld and its surrounding areas and For fine mesh division, the solid70 hexahedral thermal element is used for coarse mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com