Rapid gas storage and feeding control method of supercharged engine air system based on demand torque prediction

A supercharged engine, demand torque technology, applied in the direction of engine control, electrical control, combustion engine, etc., can solve the problems of slow instantaneous torque response, poor fuel consumption and emission of supercharged engines, so as to improve the quality of air-fuel ratio control and improve power Performance, improved emissions and fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

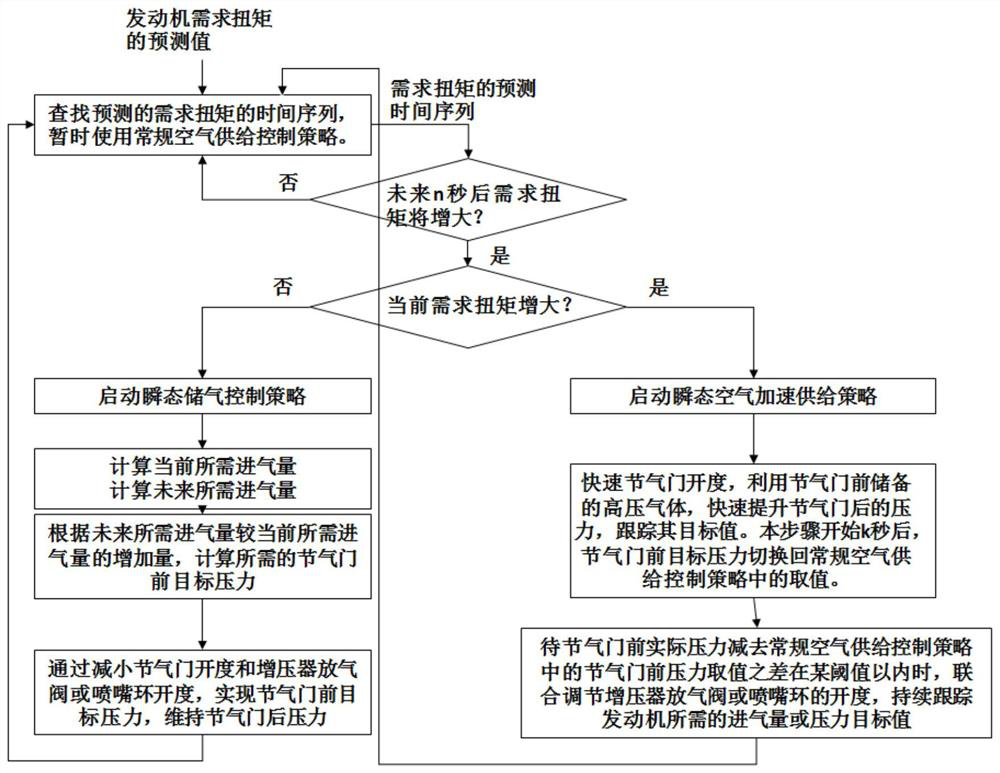

[0036] A fast gas storage and supply control method for a supercharged engine air system based on demand torque prediction, comprising the following steps:

[0037] Step 1, the conventional air supply control strategy finds the time series of the current demand torque and the predicted demand torque;

[0038] Step 2, if the predicted demand torque does not increase after n seconds in the future, return to step 1;

[0039] If the predicted demand torque increases after n seconds in the future, it is further judged whether the current demand torque increases:

[0040] If the current demand torque does not increase, start the transient air storage control strategy, and enter step 3; if the current demand torque increases, start the transient air acceleration supply strategy, and enter step 6;

[0041] Step 3, calculating the current required intake air volume according to the current demand torque, and calculating the future required intake air volume according to the predicted ...

Embodiment 2

[0048] This embodiment is further described in detail on the basis of Embodiment 1.

[0049]In the step 1, the conventional air supply control strategy can adopt any existing conventional control strategy, for details, reference can be made to the literature (Eriksson L, Nielsen L. Modeling and control of engines and drivelines. John Wiley & Sons, 2014).

[0050] In the step 3, the method of calculating the current required intake air volume according to the current demand torque is: calculate the required fuel injection volume per cylinder and cycle according to the current demand torque and the thermal efficiency of the engine, and then combine the engine air- Fuel ratio control requirements, calculate the current required intake air volume, that is, the air volume; the method of calculating the future required intake air volume according to the predicted demand torque is: calculate the required per cylinder according to the predicted demand torque and the thermal efficiency ...

Embodiment 3

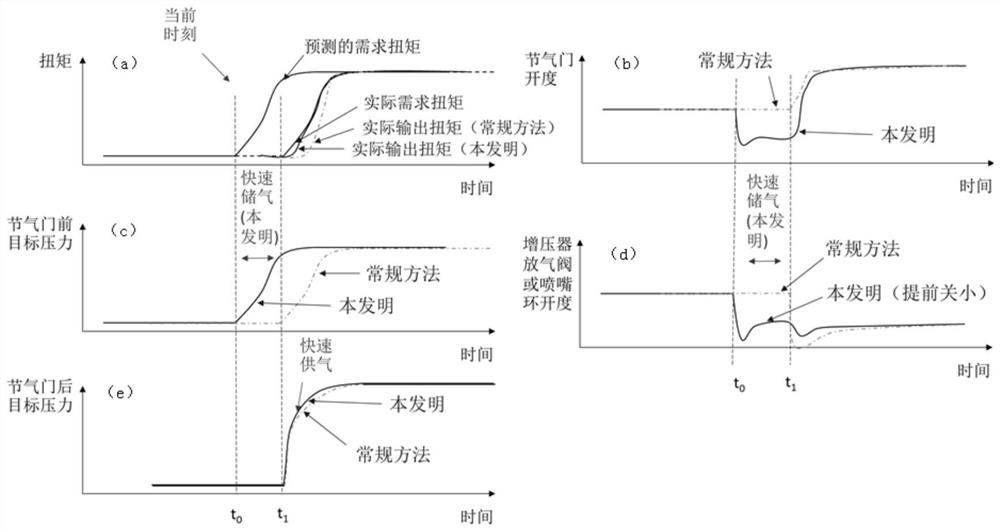

[0057] This embodiment simulates the method of the present invention, and the schematic diagrams of torque prediction, fast gas storage and fast gas supply in the present invention are as follows figure 2 shown.

[0058] at t 0 At time , the predicted demand torque starts to increase, but the current actual demand torque has not yet risen (such as figure 2 As shown in (a)), it enters the transient gas storage stage, so enter step 3 to calculate the required intake air volume. Afterwards, after calculation in step 4, the target pressure before the throttle of the transient gas storage control strategy ( figure 2 Shown in (b)) begins to rise, which is higher than the pre-throttle target pressure calculated by conventional methods. In order to track the target pre-throttle pressure, in the adjustment of step 5, ( figure 2 Shown in (e)) the opening of the blow-off valve or nozzle ring of the supercharger is reduced (less than the value of the conventional method, because t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com