Automobile door lock and automobile

A technology for car door locks and deadbolts, applied in vehicle locks, electric locks, building locks, etc., can solve the problems of large space occupied by the transmission structure, the overall volume of the car door lock, and the complex transmission of the transmission structure, and achieve volume reduction. Small, direct kinetic energy transfer, the effect of simplifying the internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

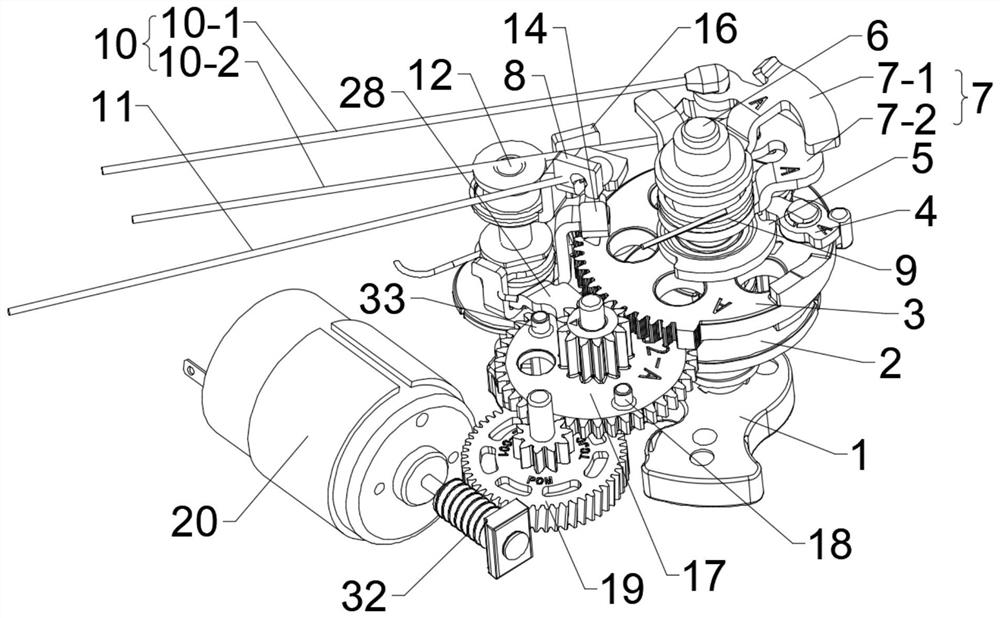

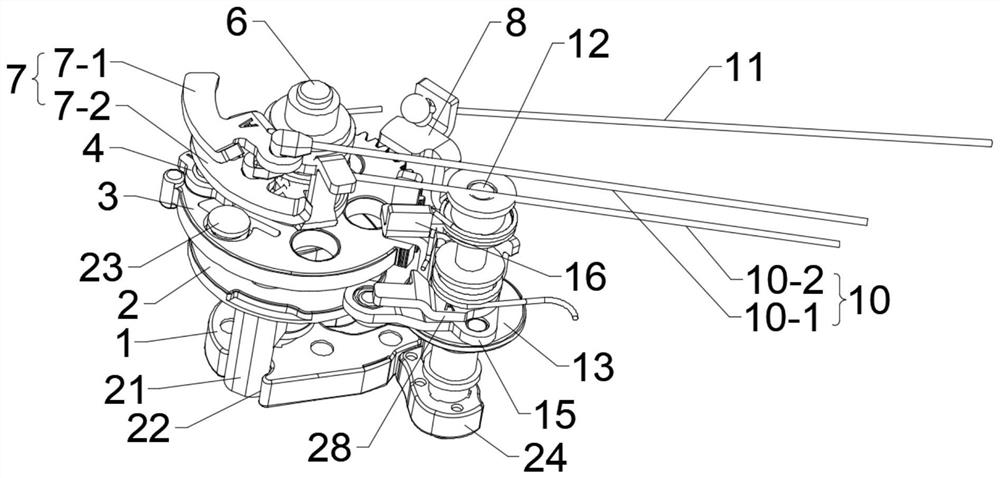

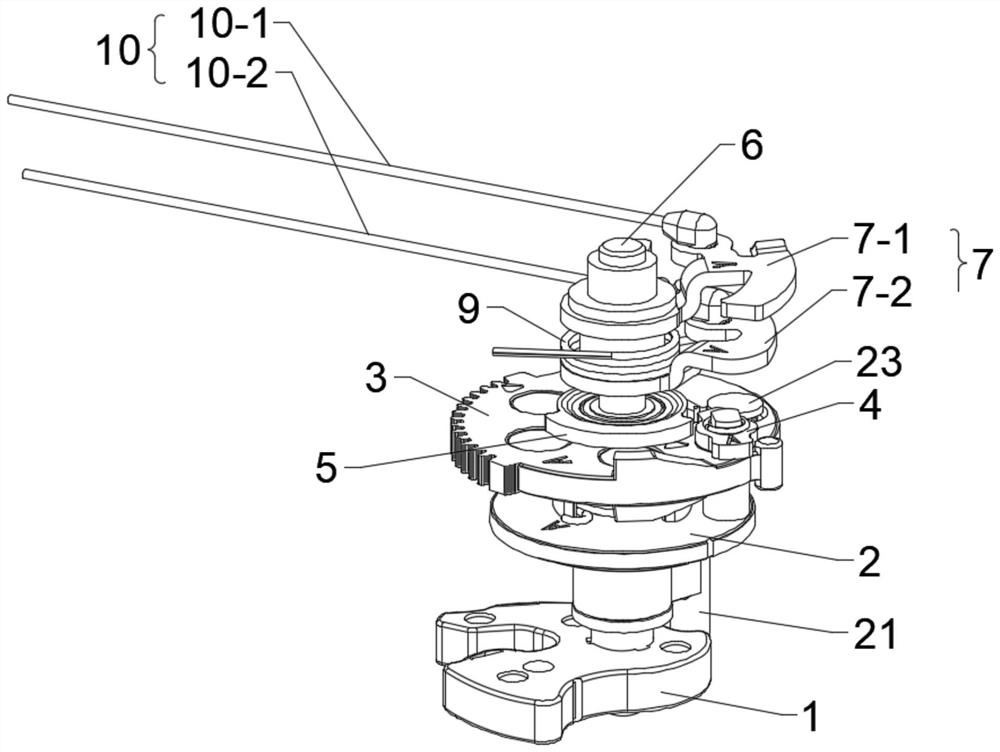

[0047] Such as Figure 1-6 As shown, this embodiment provides a car door lock, including: a coaxial and stacked locking structure with a deadbolt 1 and a rotating member 3; The clutch part 4 coaxially rotates or separates; the brake part 24 clamps the lock tongue 1 to realize locking; the first unlocking part is used to drive the brake part 24 to unlock with the lock tongue 1 .

[0048]The solution of this embodiment has the following effects, wherein the lock bolt 1 cooperates with the matching lock cylinder on the outer vehicle pillar to realize locking the vehicle door. Through the contact between the set clutch part 4 and the dead bolt 1, the dead bolt 1 is driven to rotate coaxially with the rotating part 3, and the clutch part 4 can be separated from the dead bolt 1 at the same time, so that the rotating part 3 cannot continue to drive the dead bolt 1 to rotate, and can Stopping the locking action improves the user experience, and the locking action can be stopped at an...

Embodiment 2

[0077] This embodiment provides a car door lock. The difference between this embodiment and Embodiment 1 lies in that the connection relationship between the linkage component 15 and the braking member 24 in this embodiment can be as follows. The other structures of this embodiment are completely the same as those of Embodiment 1.

[0078] In this embodiment, the linkage part 15 and the brake part 24 are integrally formed. Both the linkage part 15 and the brake part 24 can rotate on the axis of the second shaft 12. When the linkage part 15 rotates, the brake part 24 rotates at the same time. Thereby realizing unlocking.

Embodiment 3

[0080] This embodiment provides a car door lock. The difference between this embodiment and Embodiment 1 is that the first unlocking component and the second unlocking component in this embodiment may have the following structures. The other structures of this embodiment are completely the same as those of Embodiment 1.

[0081] In this embodiment, the first unlocking part includes a first pull cord and a first hook, and the second unlocking part includes a second pull cord and a second hook. The two hooks cooperate with the hook block. When the first pull rope or the second pull rope is pulled to move the first hook or the second hook, the hook block is driven to move together, thereby realizing the rotation of the linkage part 15, and the linkage part 15 drives the brake. The piece 24 moves away from the deadbolt 1, thereby realizing unlocking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com