Elevator traction machine failure judgment method and system based on current monitoring technology

A technology for elevator traction machine and fault determination, which is applied in the elevator field, can solve the problems of monitoring system error, abnormal operation warning and monitoring of the traction machine, and elevator failure, etc., and achieves the effect of improving operation safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The application scheme is further described as follows:

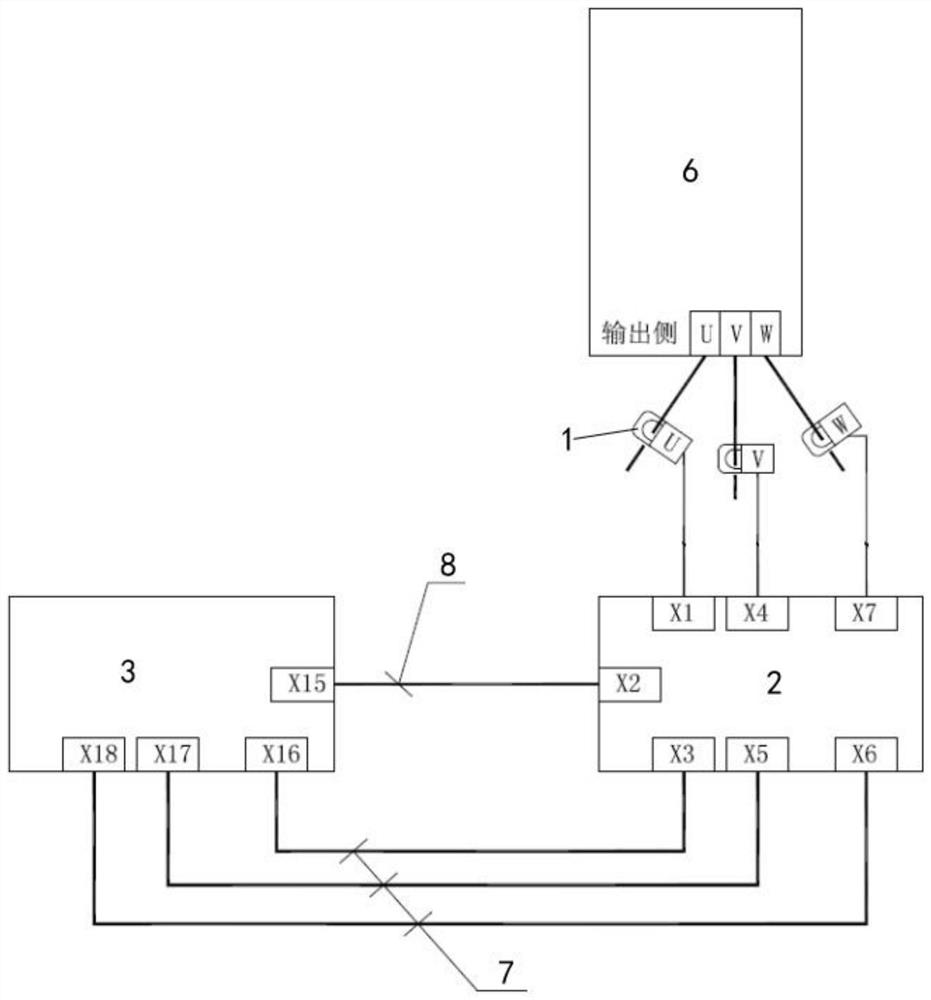

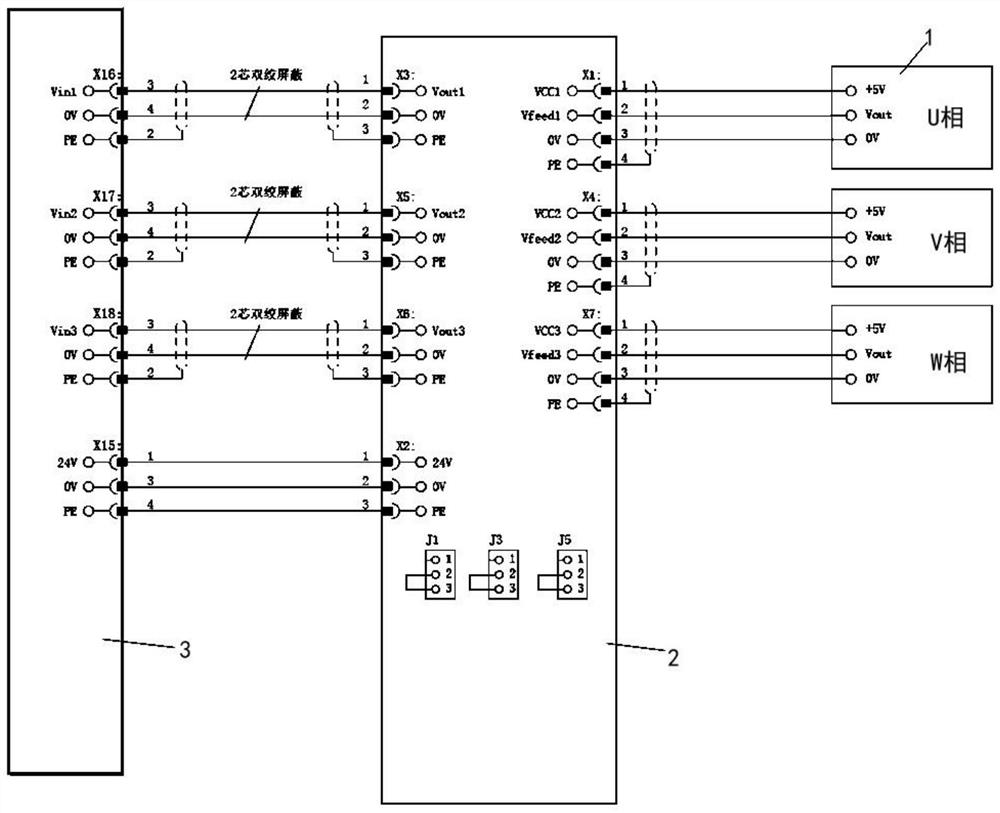

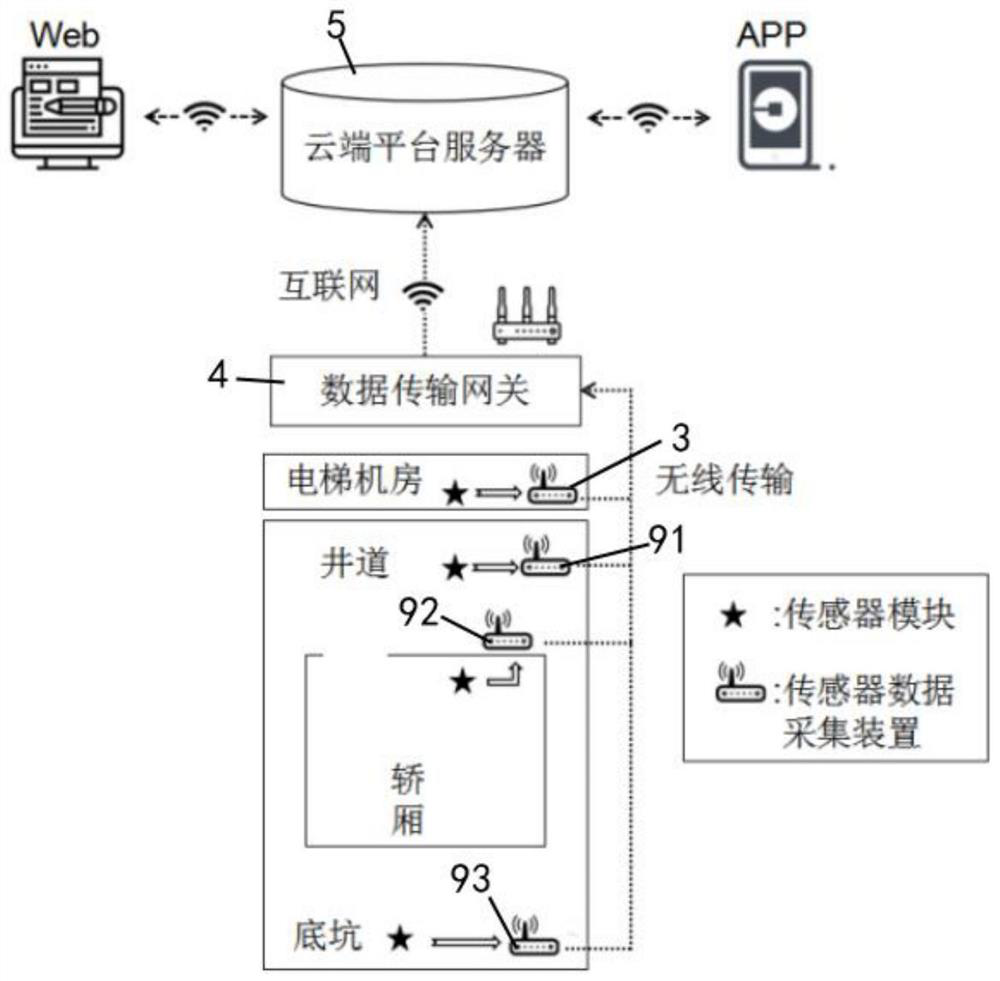

[0034] See attached Figures 1 to 3 , an elevator traction machine fault determination system based on current monitoring technology, which includes a current sensor 1, a signal box 2, an acquisition board 3, a data transmission gateway 4 and a cloud platform server 5; the current sensor 1 is connected to the traction machine Frequency converter 6 output terminals; the signal box 2 is connected between the current sensor 1 and the acquisition board 3, and is used to amplify the electrical signal collected by the current sensor 1; the acquisition board 3 includes a three-phase current collector, a processor And wireless communicator, the input end of described three-phase current collector is connected with the output end of signal box, and its output end is connected processor, and described processor is connected to cloud platform server 5 by wireless communicator, data transmission gateway 4; The cloud platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com