Material transportation device for closed installation of corridor

A technology for transportation devices and corridors, applied in the field of material transportation devices, can solve problems such as inability to use large machinery and difficulties in material transportation, and achieve the effects of improving construction efficiency, low cost, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

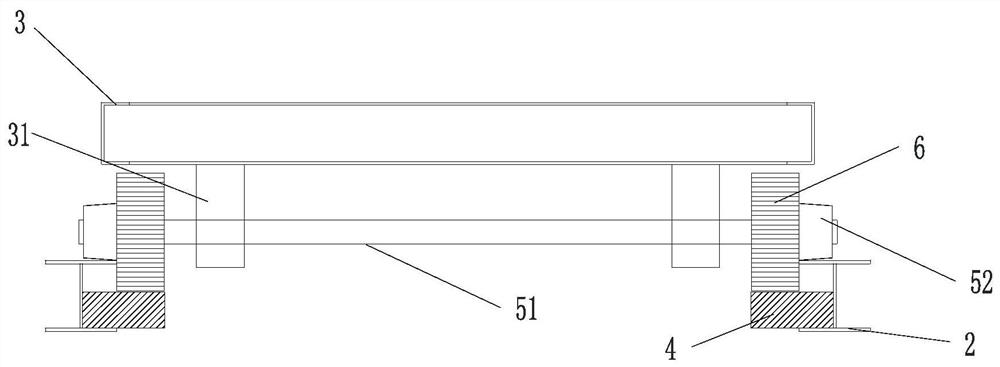

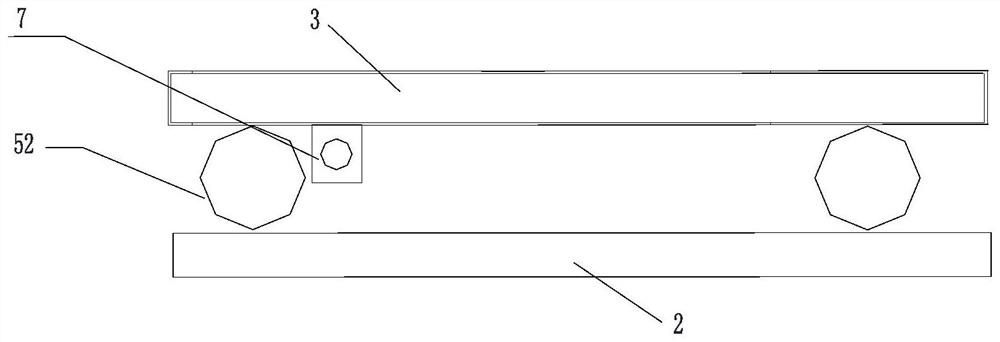

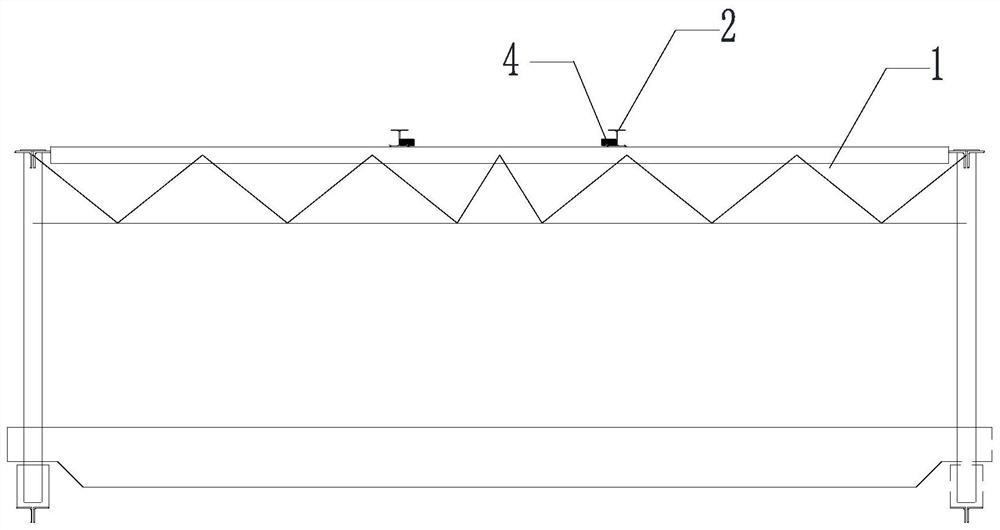

[0025] Such as Figure 1~4 As shown, the present invention discloses a material transportation device for the closed installation of corridors. A truss 1 is arranged on the top of the corridor, and the truss 1 has a slope; specifically, the transportation device includes a transportation trolley and two oppositely arranged Track 2: the transport trolley includes a frame 3 and two wheel pairs 5 located below the frame 3, and the two wheel pairs 5 are respectively located on both sides of the bottom length direction of the frame 3; each wheel pair 5 includes an axle 51 and the wheels 52 installed at both ends of the axle 51, and the vehicle frame 3 is equipped with a driving device 7 for driving the wheels 52 forward; the two rails 2 are welded and fixed on the truss 1, and the two wheels 5 The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com