Preparation method and application of hollow covalent triazinyl framework material loaded with MoS2 quantum dots

A framework material and triazine-based technology, which is applied in the field of preparation of hollow covalent triazine-based framework materials, can solve the problems of tediousness, harsh preparation conditions, and easy aggregation of nanosheets, and achieve economical, environmentally friendly, and simple preparation processes Moreover, the effect of promoting transfer and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 The present invention is loaded with MoS 2 Preparation method of quantum dot hollow covalent triazine-based framework material:

[0032] The loading of the present invention has MoS 2 The preparation method of quantum dot hollow covalent triazine-based framework material can be divided into three steps:

[0033] (1) Preparation of silica nanospheres: adding ethanol, tetraethyl orthosilicate, deionized water and 25% to 28% ammonia water to a three-necked flask at a volume ratio of 220:18:30:10.5, Stir vigorously at 40°C for 2 hours, centrifuge the solution, wash the product three times with water and ethanol, and dry it. After grinding, a white powder is obtained, which is an ordered silica template.

[0034] (2)MoS 2 Preparation of quantum dot solution: 120mg of MoS 2 Disperse the powder in 60ml of 1mg / ml tannic acid solution, in a water bath at 25°C, continue to sonicate (300w power) for 4 hours, and then centrifuge at 10,000 rpm for 10 minutes to obta...

Embodiment 2

[0036] Embodiment 2 The present invention is loaded with MoS 2 Structural characterization of quantum dot hollow covalent triazine-based framework materials.

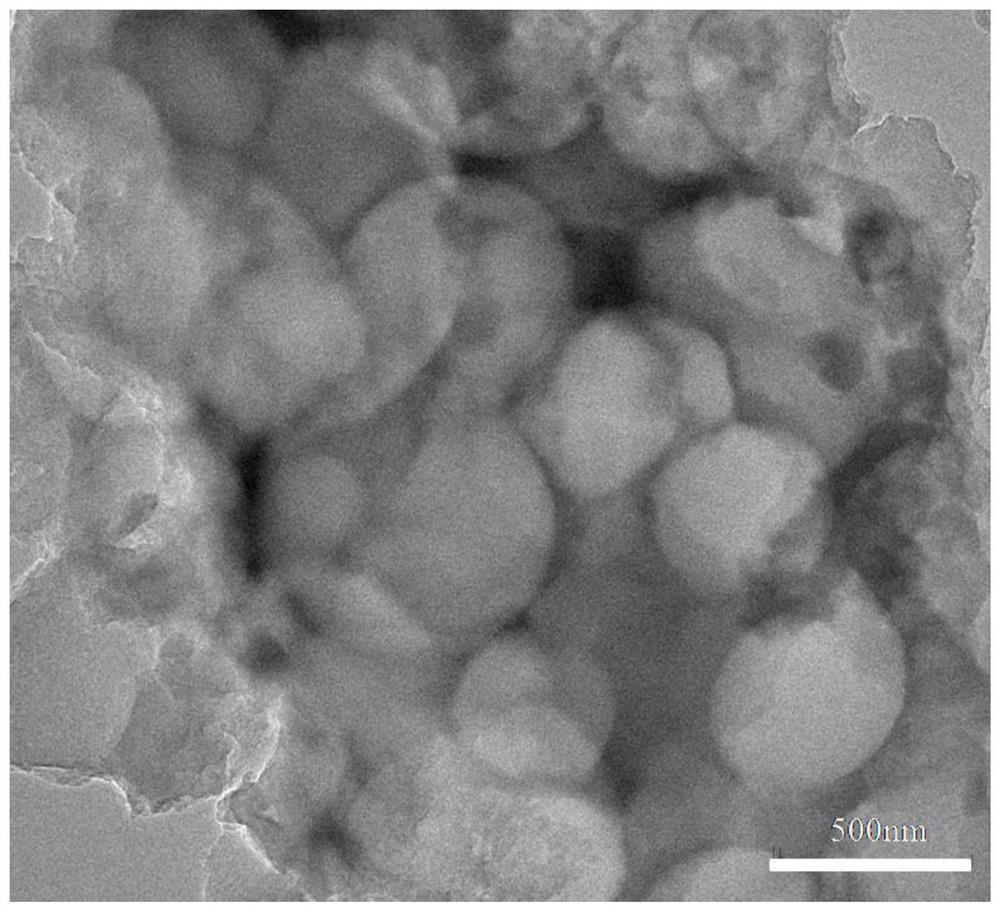

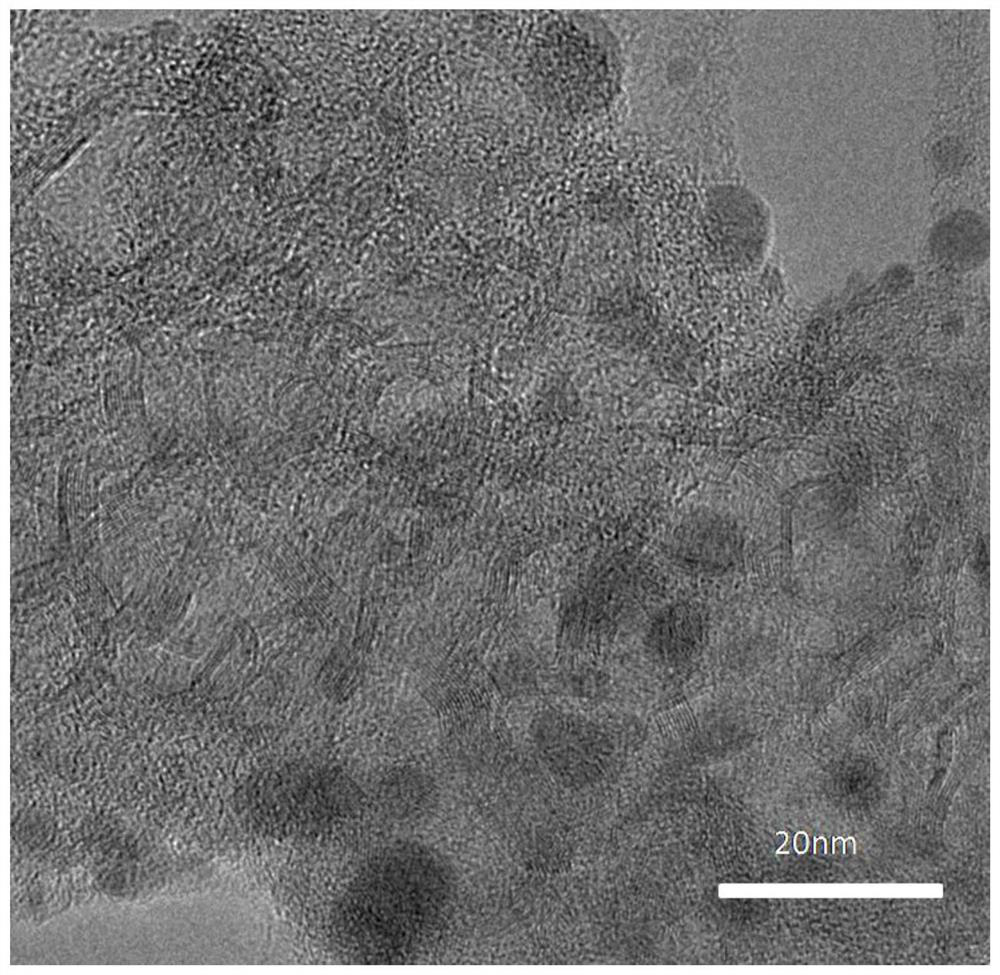

[0037] (1) Morphological characterization

[0038] SEM and TEM images ( Figure 1-2 ) shows a unique multilayered and interconnected porous structure, and the loaded MoS 2 There is no obvious collapse of the channel behind the quantum dots, indicating that the structure of the material is stable and strong. HRTEM image ( image 3 ) clearly shows that MoS 2 The average diameter of quantum dots is about 5nm, and MoS 2 The quantum dots are evenly distributed on the surface of the hollow covalent triazine-based framework material.

[0039] (2) Crystal form characterization

[0040] pass( Figure 4 ) can be seen, in the loaded MoS 2 Before and after the quantum dots, the hollow covalent triazine-based framework materials have two obvious diffraction peaks, which respectively correspond to the (100) crystal plane of ...

Embodiment 3

[0045] Embodiment 3 The present invention is loaded with MoS 2 Quantum dot hollow covalent triazine-based framework material photolyzes water to generate hydrogen under visible light

[0046] loaded with MoS 2 The preparation process of quantum dot hollow covalent triazine-based framework material is the same as Example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com