RTM automatic glue mixer

A glue mixing machine, automatic technology, applied in the direction of mixer, mixer accessories, dissolving, etc., to achieve the effect of preventing misoperation, preventing wrong proportioning, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

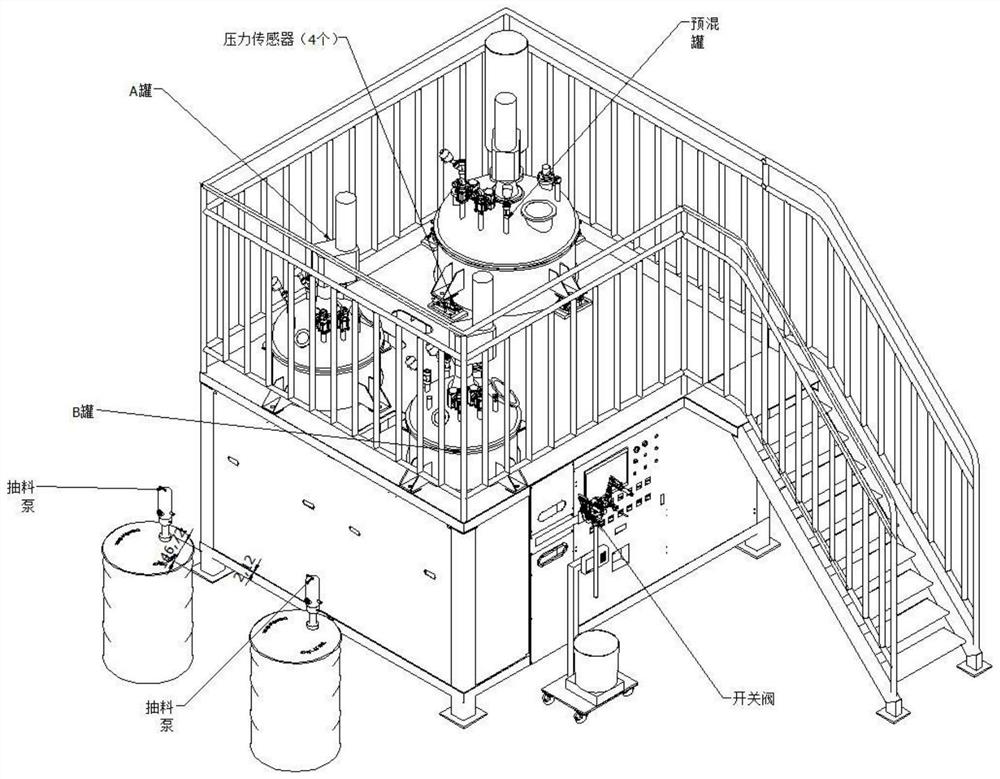

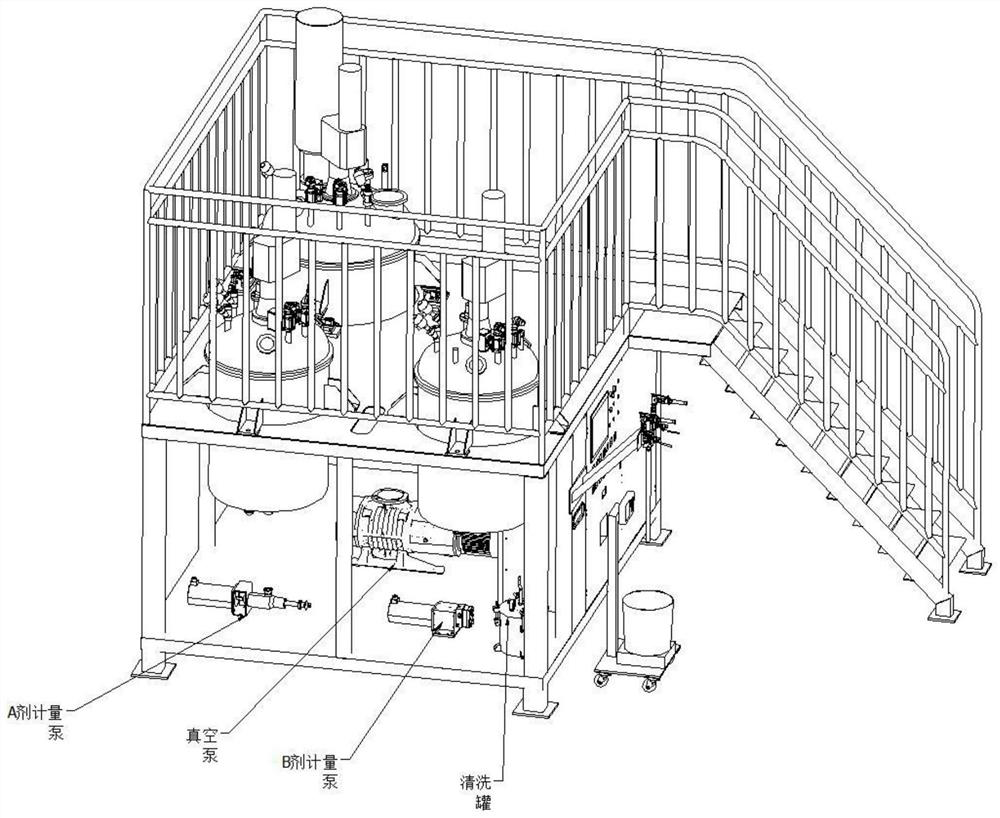

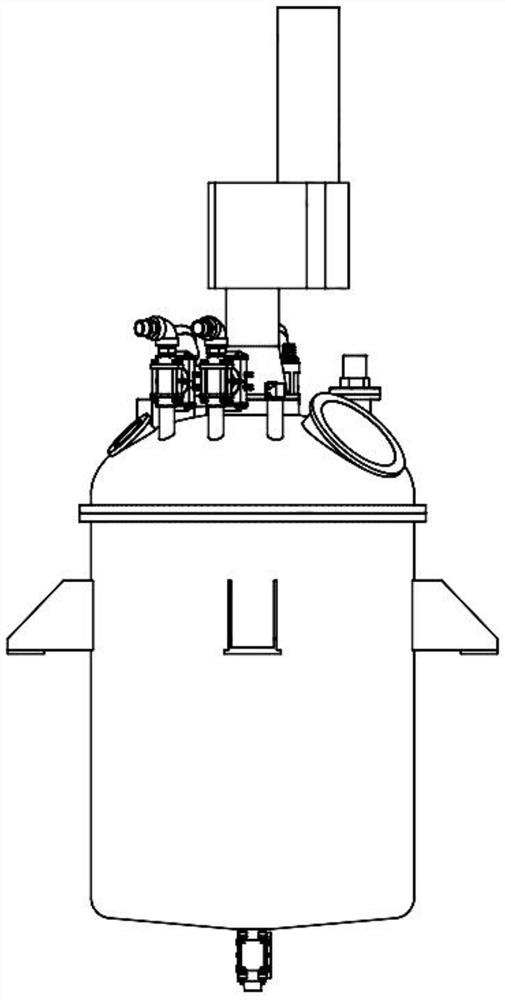

[0024] Such as Figure 1 to Figure 5 As shown, an RTM automatic glue mixing machine includes A tank, B tank, premix tank, A agent raw material tank and B agent raw material tank; the premix tank is also equipped with a pneumatic diaphragm pump and a premix reflux automatic switch valve. The discharge valve at the bottom of the mixing tank is connected with the pneumatic diaphragm pump, the automatic switch valve for premixing backflow and the upper end of the premixing tank in sequence through the pipeline; and the pipeline of the discharge valve at the bottom of the premixing tank is a pipeline with a heated pipeline; The motor of the stirring device of the mixing tank is 1.5KW; the motor of the stirring device of the A tank is 1.5KW; the motor of the stirring device of the B tank is 0.75KW; Agent A metering pump and agent B metering pump; agent A metering pump is a screw metering pump, suitable for high viscosity glue with additives in the glue; agent B metering pump is a ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com