A control system for durability test of engine front end gear train accessories

A durability test, front-end gear train technology, applied in general control systems, engine testing, control/regulation systems, etc., can solve problems such as single durability assessment, lack of test control systems, and long bench resource occupation for durability tests. Achieve the effect of accurate testing, accurate test results, and saving development and verification time and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

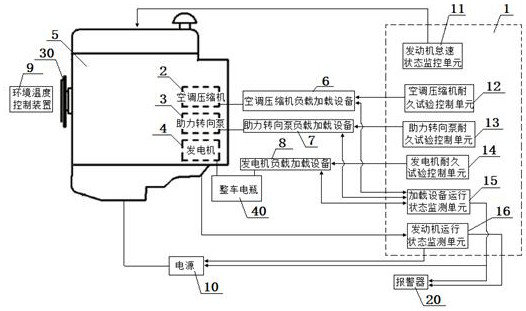

[0049] see figure 1 , a control system for the durability test of front end gear train accessories of an engine, comprising a controller 1, a system air conditioner compressor 2, a power steering pump 3, a generator 4, and an ambient temperature control device 9, the air conditioner compressor 2, power steering pump 3 Correspondingly connected with the air conditioner compressor load loading device 6 and the power steering pump load loading device 7 respectively, the generator 4 is connected with the generator load loading device 8 through the vehicle battery 40, and the engine idle speed State monitoring unit 11, air conditioner compressor endurance test control unit 12, power steering pump endurance test control unit 13, generator endurance test control unit 14, loading equipment operation state monitoring unit 15, engine operation state monitoring unit 16, the engine idle speed The state monitoring unit 11 is connected with the engine 5 signal, and the air-conditioning comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com