Dustfall equipment for cutting corrugated board

A corrugated cardboard and cutting technology, which is applied in the field of dust suppression equipment for corrugated cardboard cutting, can solve the problems of air pollution and affect the health of staff, and achieve the effect of convenient fixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

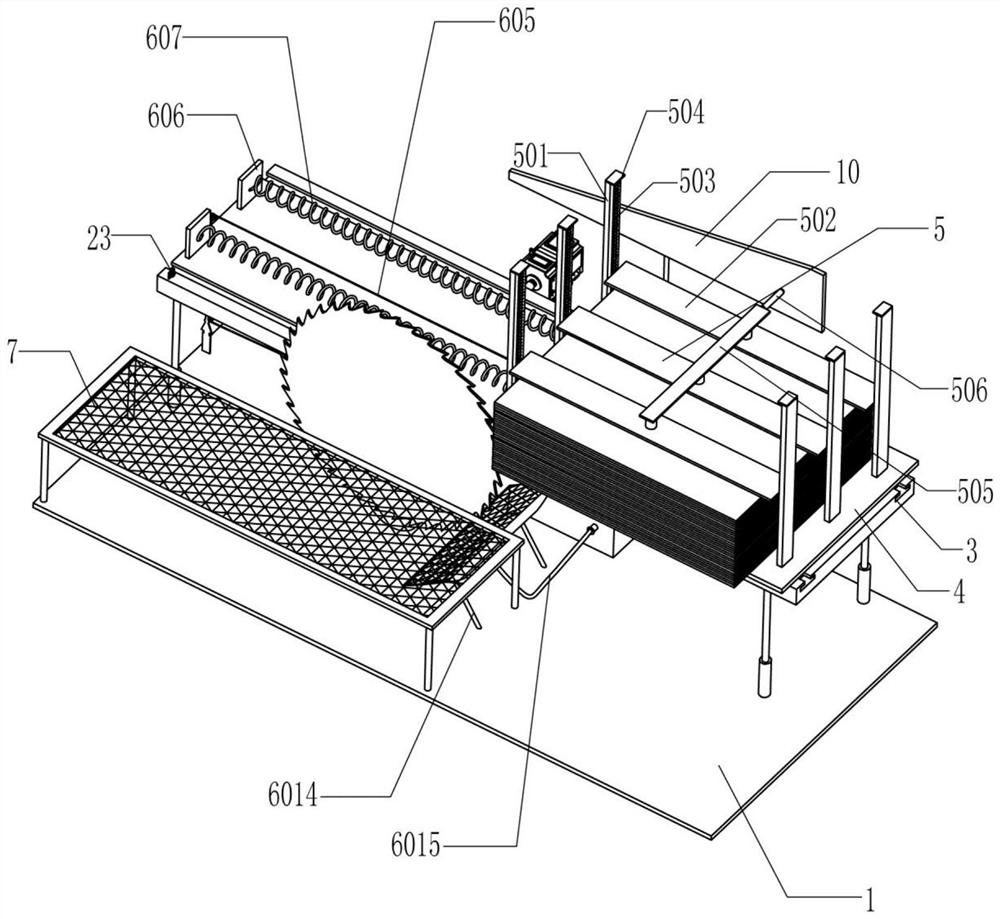

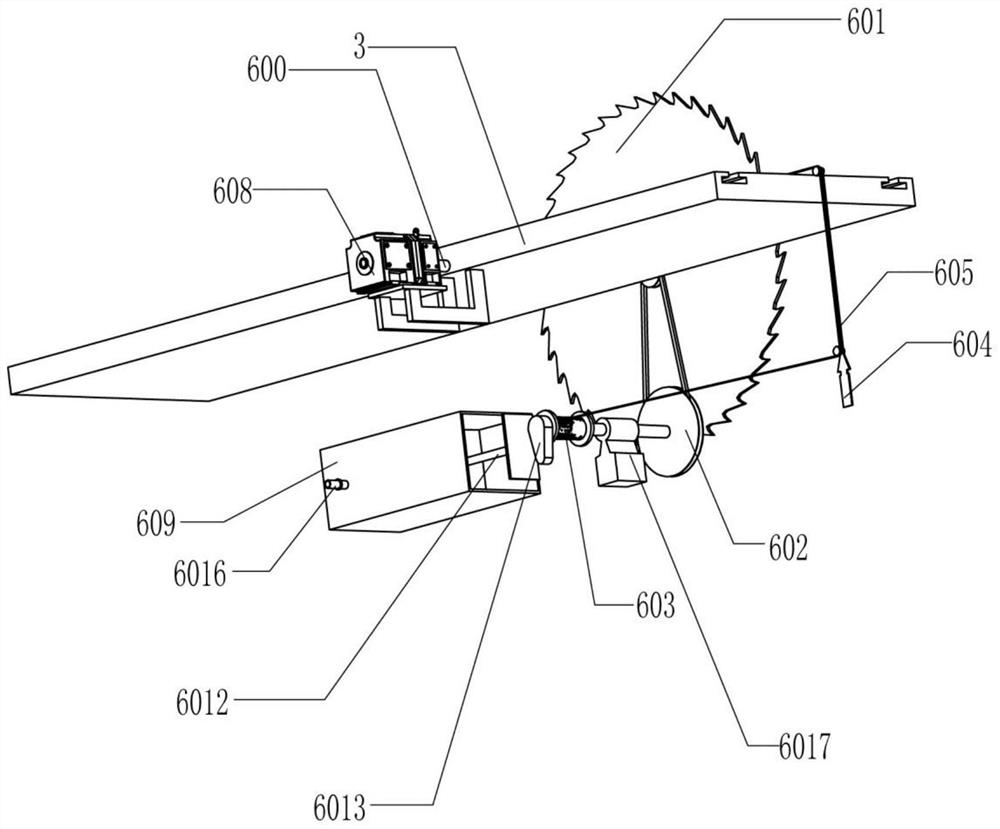

[0021] A kind of dust suppression equipment for cutting corrugated cardboard, such as Figure 1-5 As shown, it includes a base plate 1, legs 2, guide rail plate 3, sliding plate 4, corrugated cardboard clamping and fixing device 5, corrugated cardboard cutting and dust suppression device 6 and placing net plate 7, and the base plate 1 is a 1cm thick Cuboid and the bottom plate 1 is fixedly installed with four legs 2 by welding, the guide rail plate 3 is fixedly installed on the four legs 2 by welding, and the sliding plate 4 is slidably installed on the guide rail plate 3 , the sliding plate 4 can move left and right along the guide rail plate 3, the corrugated cardboard clamping and fixing device 5 is installed on the sliding plate 4, and the corrugated cardboard cutting and dust suppression device 6 is installed on the base plate 1 and the guide rail plate 3. The placing screen 7 is fixedly installed on the bottom plate 1 by welding.

[0022] The corrugated cardboard clampi...

Embodiment 2

[0026] On the basis of Embodiment 1, such as Figure 1-5 As shown, a pushing mechanism is also included, and the pushing mechanism includes a second guide rail 8, a sliding block 9, a wedge frame 10, a fourth compression spring 11, a sliding frame 12, a first wedge rod 13, a fifth compression spring 14, The first guide wheel 15, the second guide wheel 16, the sliding sleeve 17, the second wedge rod 18, the sixth compression spring 19 and the second pull cord 20, the second guide rail 8 is vertically arranged and installed on the bottom plate 1 by bolts The sliding block 9 is slidably installed on the second guide rail 8, the sliding block 9 can move back and forth along the second guide rail 8, the wedge frame 10 is installed on the sliding block 9 through bolts, and the fourth compression spring 11 is installed between the second guide rail 8 and the sliding block 9, the "L"-shaped sliding frame 12 is fixedly installed on the bottom plate 1 by welding, and the first wedge-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com