Six-axis cooperative robot development platform based on rapid control prototyping system

A prototype system and rapid control technology, which is applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of difficult writing of control codes and difficult implementation of advanced algorithms, and achieve high-precision control, fast motion control, and reduced effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

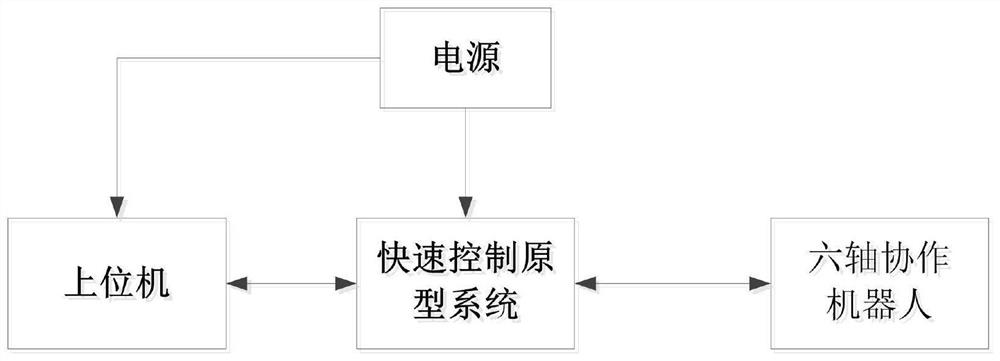

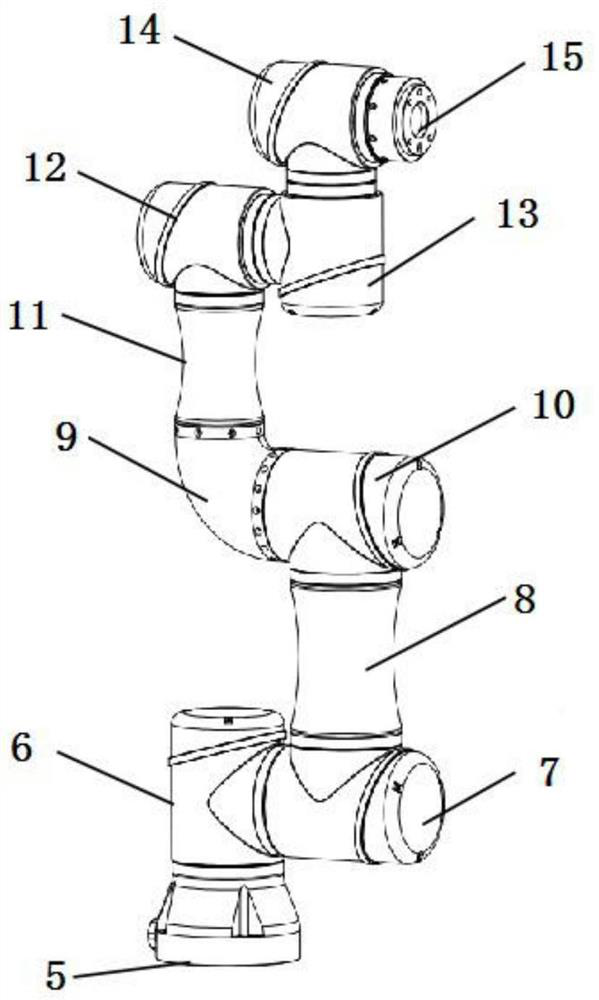

[0046] Such as figure 1 As shown, a six-axis collaborative robot development platform based on rapid control prototyping system, including:

[0047] The upper computer adopts a PC, and the development software is loaded on the PC; the upper computer is used to observe and display the real-time information of the six-axis collaborative robot, input control instructions and adjust parameters online; the development software loaded on the PC is embedded by MATLAB / Simulink and CCS Compiler and other tool software, these tool software combined with the function of automatic code generation can help people with poor programming foundation to complete the development of various control algorithms in a short time.

[0048] Power supply, providing AC 220V power supply for the development system of the upper computer, and DC 48V power supply for the rapid control prototype system;

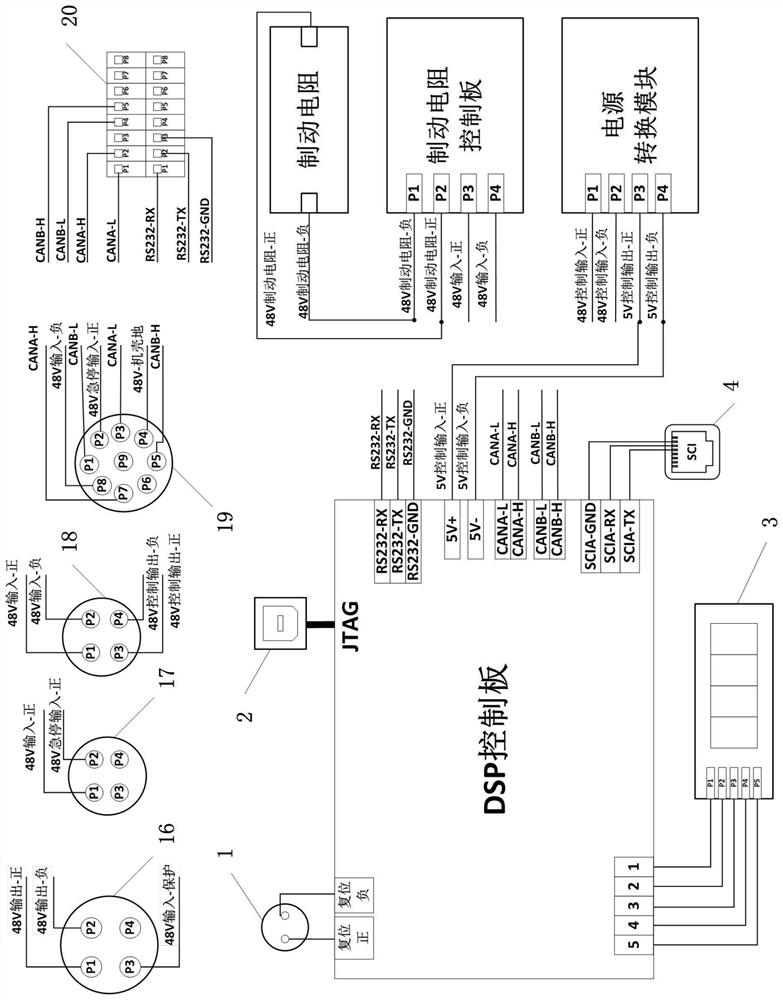

[0049] The rapid control prototype system is an open control platform for rapid control code generation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com