Paint spraying equipment for cylindrical surface

A technique for spraying equipment and cylindrical surfaces, which is applied in spray booths, spray devices, chemical instruments and methods, etc. It can solve the problems of hand-held paint spraying machines such as fatigue of limbs, inability to paint uniformly, etc., to ensure quality and reduce paint waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

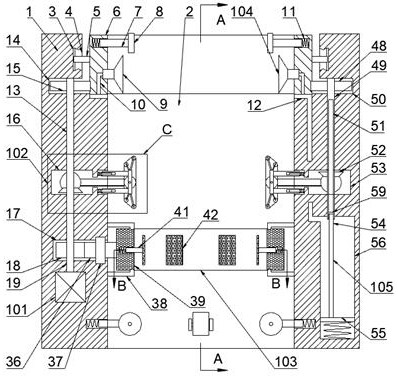

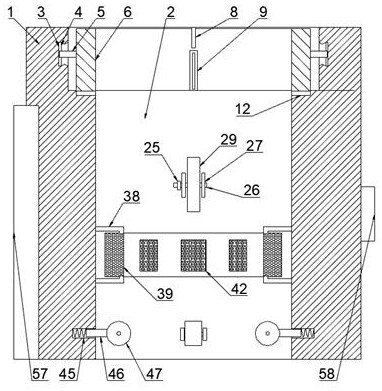

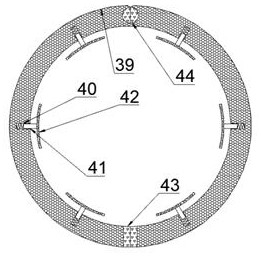

[0016] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0017] A cylindrical surface painting equipment described in conjunction with accompanying drawings 1-5 includes a frame 1 and a hinge 57 for hinged frame 1 and a switch 58 for locking the frame 1, the frame 1 is two semi-circular columns and is hinged and closed by the hinge 57 to form a circular column. The inner ring of the frame 1 encloses the working chamber 2, and the top of the frame 1 is provided with a track groove 3. A ring sleeve 6 at the same height as the track groove 3 is installed in the working chamber 2, and two support shafts 5 are fixedly arranged on the outer ring surface of the ring sleeve 6 symmetrically. The sheave 4 matched with the track groove 3, the inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com