Binocular Vision Calculation Normal Vector Method for Automatic Hole Making and Automatic Drilling and Riveting of Aircraft Panels

An aircraft wallboard, automatic drilling and riveting technology, applied in the direction of optical devices, image analysis, instruments, etc., to achieve the effect of improving quality and efficiency, accurate normal vector values, and solving normal vector problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

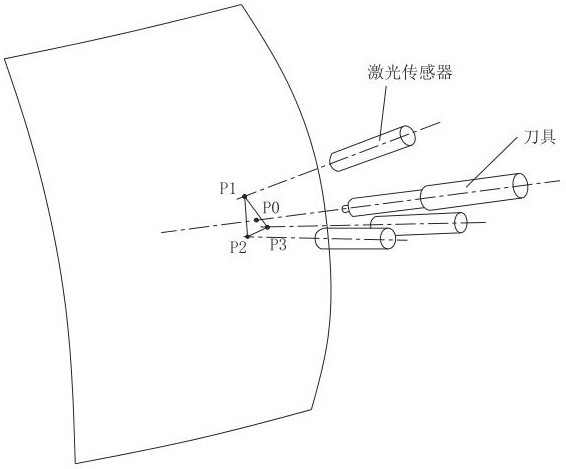

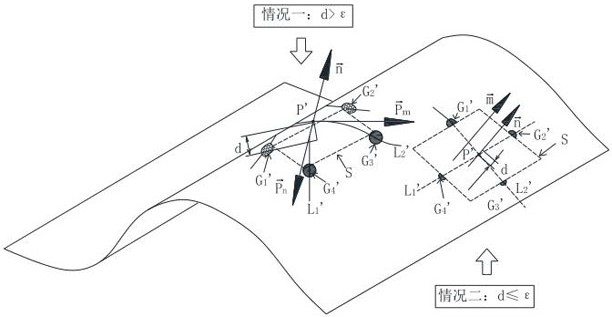

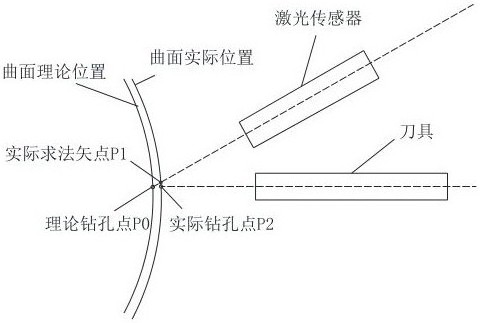

[0044] See Figure 4 to Figure 8, the present invention includes an end effector 1, a structured light emitter 2, a right camera 3 and a left camera 4; the structured light emitter 2, the right camera 3 and the left camera 4 are installed in front of the end effector 1 with adjustable angles , the method of finding the normal vector is:

[0045] (1) Use the structured light emitter 2 to project an 8×8 matrix light to the aircraft wall panel 5 around the position where holes need to be made or drilled and riveted. The matrix light will form a projection on the surface of the wall panel 5. There are 64 intersection points in this matrix.

[0046] (2) Use the binocular vision system to calculate the actual coordinates of the intersection point of the projection matrix (x 1 ,y 1 ,z 1 ) (x 2 ,y 2 ,z 2 )...(x 64 ,y 64 ,z 64 ); Calibrate the right camera 3 and the left camera 4, use the right camera 3 and the left camera 4 to shoot the projection matrix, and the photos taken...

Embodiment 2)

[0066] This embodiment is basically similar to Embodiment 1, the differences are: (1) Use a structured light emitter 2 to project a 9×9 matrix light to the aircraft wall panel 5 around the position that needs to be drilled or riveted, and the matrix light will The surface of the wall panel 5 forms a projection, and the matrix has 81 intersection points in total.

[0067] (2) Use the binocular vision system to calculate the actual coordinates of the intersection point of the projection matrix (x 1 ,y 1 ,z 1 ) (x 2 ,y 2 ,z 2 )...(x 81 ,y 81 ,z 81 ); Calibrate the right camera 3 and the left camera 4, use the right camera 3 and the left camera 4 to shoot the projection matrix, and the photos taken by the right camera 3 and the left camera 4 are respectively subjected to edge detection, edge fitting, and feature point extraction to obtain the photos The intersection point of the projection matrix in the middle, use stereo matching to determine the corresponding relationshi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com