Connecting rod appearance size detection system and detection method

A technology of detection system and appearance size, which is applied in the direction of measuring devices, optical testing defects/defects, conveyor objects, etc., can solve the problems of low detection efficiency and low detection accuracy of the appearance size of connecting rods, and achieve the goal of saving material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

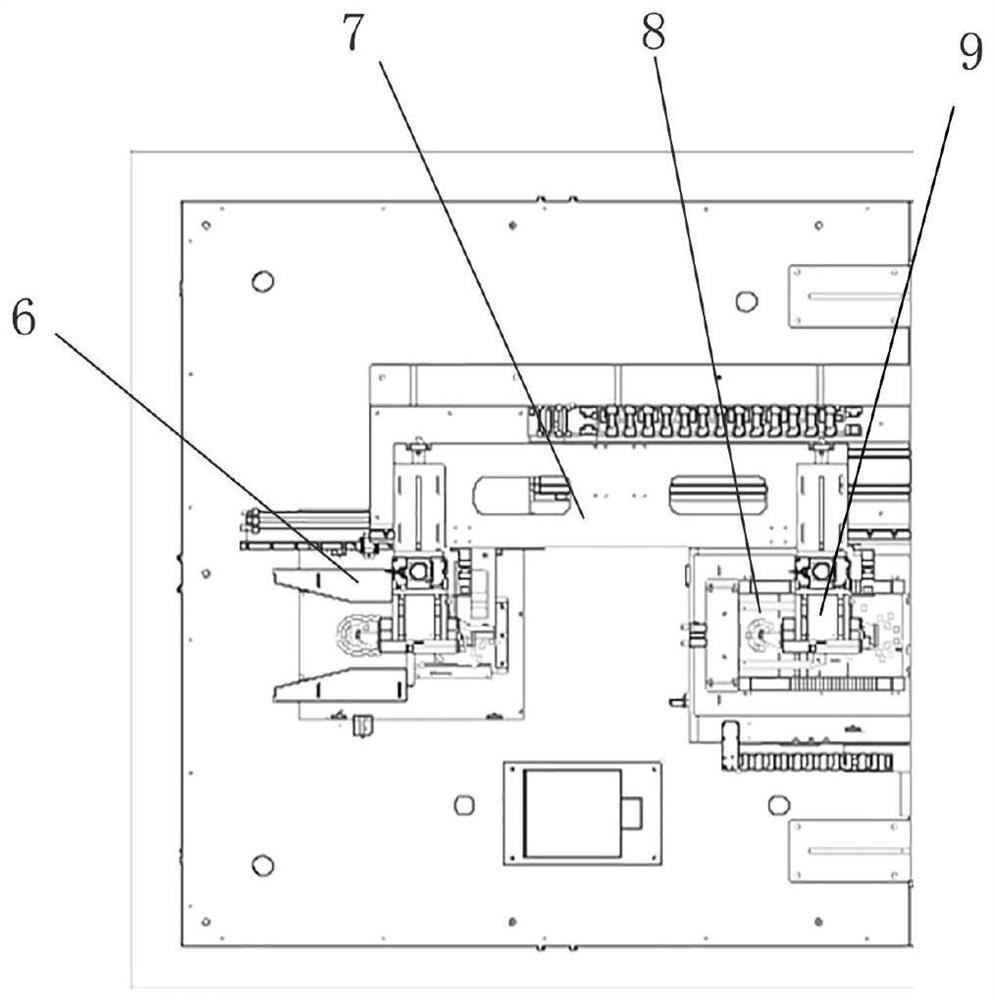

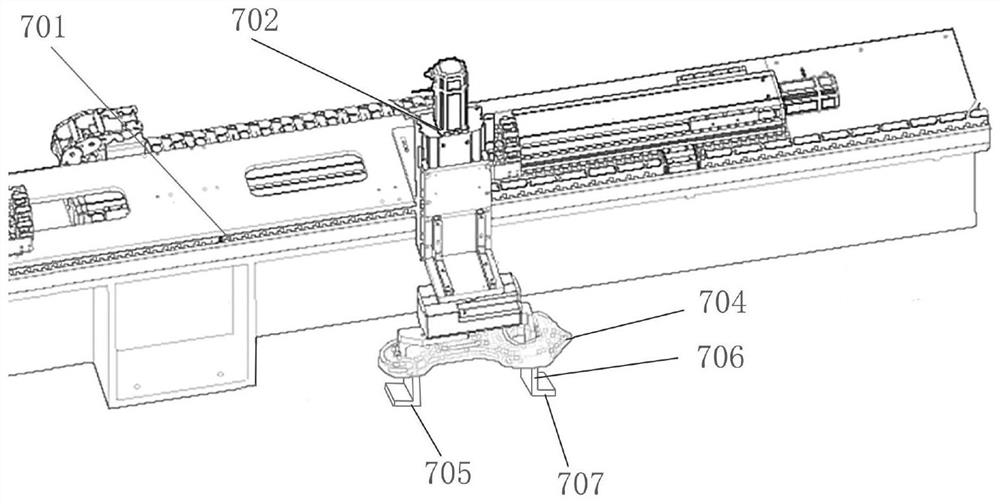

[0073] Embodiment 1, the external dimension detection system of connecting rod, such as Figure 1-5 As shown, it includes a feeding mechanism 6 , a transport mechanism 7 , a moving mechanism 8 and a laser detection system 9 .

[0074] The feeding mechanism 6 is connected to the moving mechanism 8 through the conveying mechanism 7 , and the moving mechanism 8 is provided with a laser detection system 9 .

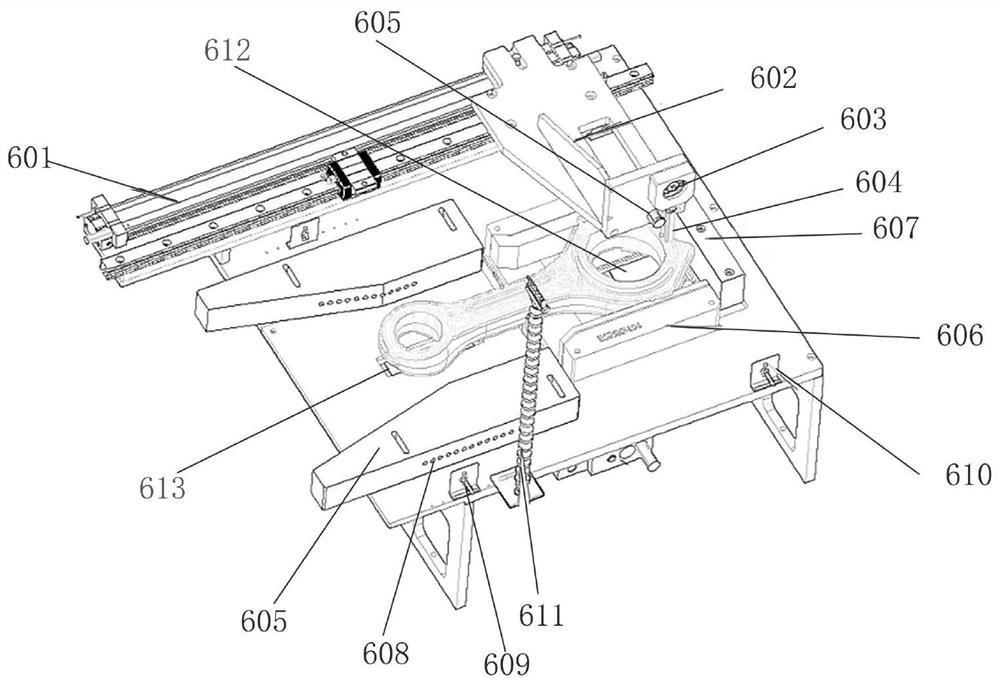

[0075] The feeding mechanism 6 includes a material shifting structure, a feeding guide rail 601 and a placement table 614;

[0076] Two placing platform limit blocks 1 605, two placing platform limiting blocks 2 606 and a placing platform stopper 607 are installed above the placing platform 614. Placement platform limit block 1 605, placement platform limit block 2 606 and placement platform stopper 607 are arranged sequentially along the direction from the head end to the tail end of the feeding mechanism 6, two placement platform limit block 1 605 and two placement platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com